Automatic feeding tapping machine

An automatic feeding and tapping machine technology, applied in the field of machine tools, can solve problems such as difficult alignment of the center of the frosted rod, and achieve high processing efficiency, good processing consistency, and good neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

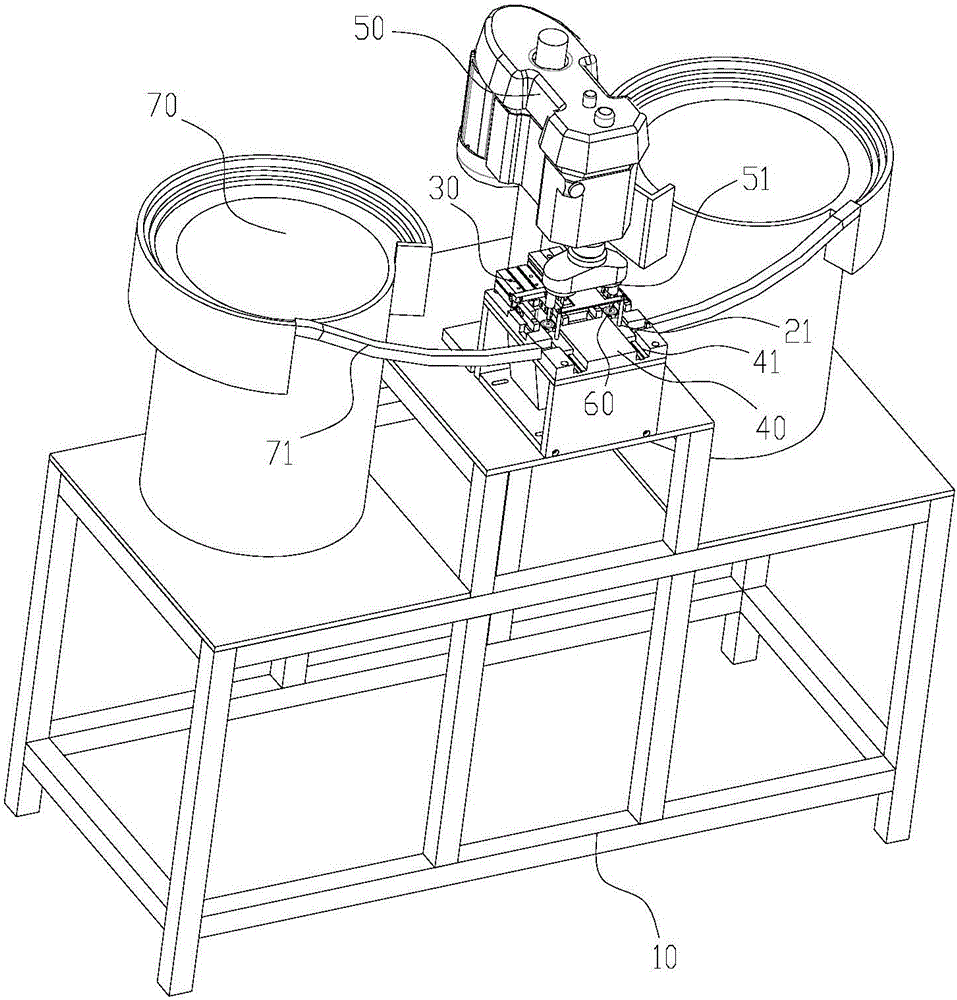

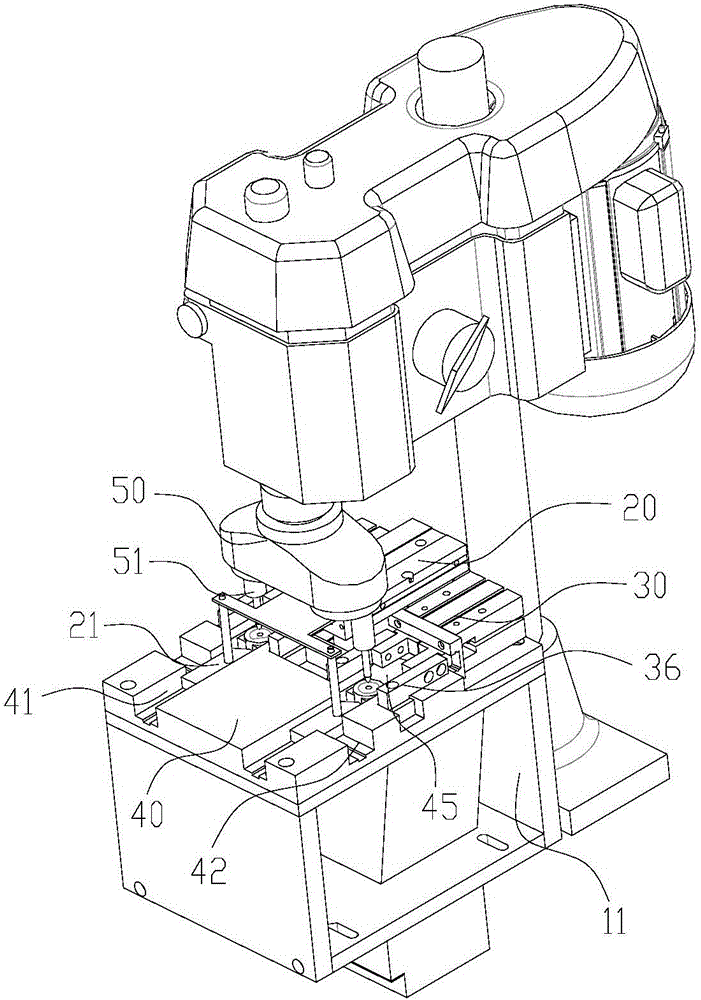

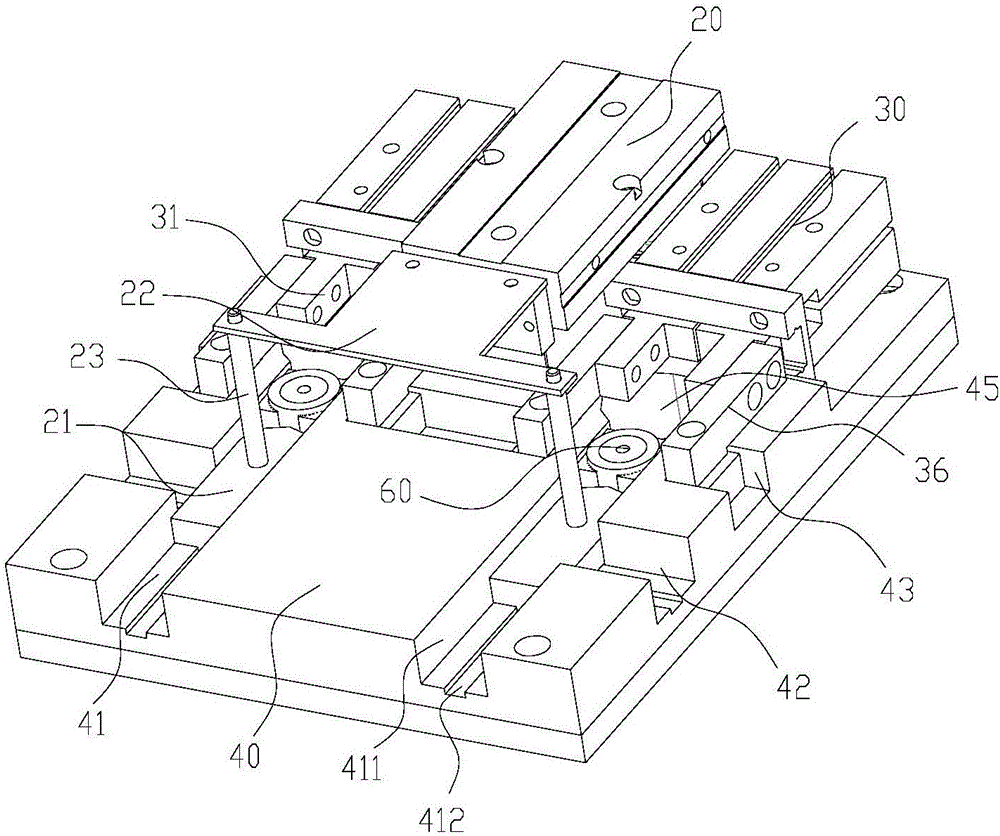

[0028] Examples, see Figure 1 to Figure 3 Shown: an automatic feeding tapping machine, including a frame 10, a machine head 50 installed on the frame 10 and a vibration plate 70 installed on the frame 10, and a tapping drill bit 51 is installed on the machine head 50 , a positioning fixture is installed on the frame 10, and the positioning fixture is installed below the tapping drill bit 51. After the workpiece 60 is clamped on the positioning fixture, the machine head 50 drives the tapping drill bit 51 to go down and tap on the workpiece 60, and the positioning The fixture includes a bottom template 40, a pusher cylinder 20 and a clamping cylinder 30. On the bottom template 40, a guide groove 41 and an inlet groove 42 connected to the guide groove 41 are provided. The guide groove 41 extends towards the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com