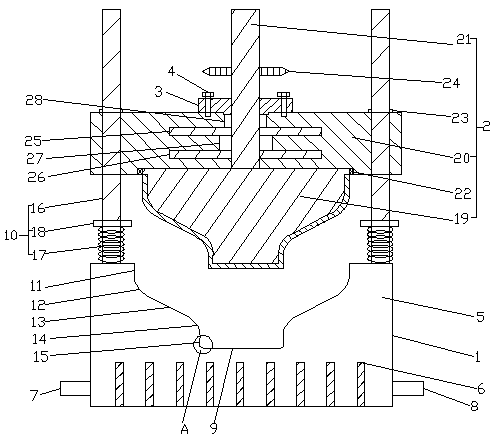

A stamping die for the shell head of a high-voltage transformer

A technology of high-voltage transformers and stamping dies, which is applied in the manufacture of inductors/transformers/magnets, forming tools, manufacturing tools, etc., which can solve the problems of high temperature heat dissipation, low breakdown resistance and poor heat resistance of the die head and other problems, to achieve the effects of good pressure resistance and impact resistance, good head formability, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

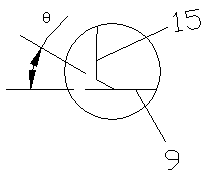

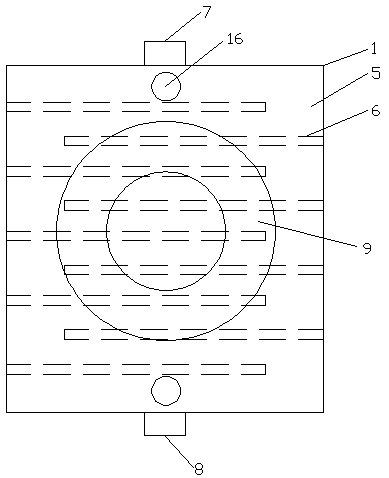

Method used

Image

Examples

Embodiment 1

[0046] The above stamping die for the head of a high-voltage transformer shell, wherein the preparation method of the heat-insulating coating is as follows:

[0047] (1) Take 21 parts by mass of nano-titanium dioxide, 12 parts of nano-tin oxide, 13 parts of nano-silicon dioxide, 6 parts of nano-zinc-aluminum oxide and 2 parts of nano-molybdenum trioxide in a ball mill, and control the speed at 1450r / min, ball mill for 2 hours, then add 8 parts of polyvinyl alcohol and 6 parts of polyvinyl pyrrolidone dispersant in turn, under the power of 560w microwave, control the stirring rate to 410r / min, the temperature is 180 ℃, and react for 3 hours to prepare the nanocomposite material ;

[0048](2) Take 17 parts of E51 bisphenol A epoxy resin and 13 parts of polypropylene by mass parts, add 4 parts of talcum powder, control the stirring rate at 145r / min, and the temperature at 150°C for 3 hours to prepare Obtain modified resin;

[0049] (3) Add 26 parts of nanocomposite materials a...

Embodiment 2

[0051] The above stamping die for the head of a high-voltage transformer shell, wherein the preparation method of the heat-insulating coating is as follows:

[0052] (1) Take 22 parts by mass of nano-titanium dioxide, 14 parts of nano-tin oxide, 11 parts of nano-silicon dioxide, 5 parts of nano-zinc-aluminum oxide and 3 parts of nano-molybdenum trioxide in a ball mill, and control the speed at 1300r / min, ball mill for 1 hour, then add 9 parts of polyvinyl alcohol and 8 parts of polyvinyl pyrrolidone dispersant in turn, under the power of 560w microwave, control the stirring rate to 350r / min, and the temperature is 210℃, react for 3 hours to prepare nanocomposites ;

[0053] (2) Take 15 parts of E51 bisphenol A epoxy resin and 10 parts of polypropylene by mass parts, add 3 parts of talcum powder, control the stirring rate at 135r / min, and the temperature at 160°C for 3 hours to prepare Obtain modified resin;

[0054] (3) Add 32 parts of nanocomposite materials and 18 parts o...

Embodiment 3

[0056] The above stamping die for the head of a high-voltage transformer shell, wherein the preparation method of the heat-insulating coating is as follows:

[0057] (1) Take 12 parts by mass of nano-titanium dioxide, 14 parts of nano-tin oxide, 8 parts of nano-silicon dioxide, 7 parts of nano-zinc-aluminum oxide and 3 parts of nano-molybdenum trioxide in a ball mill, and control the speed at 1500r / min, ball mill for 1 hour, then add 8 parts of polyvinyl alcohol and 10 parts of polyvinyl pyrrolidone dispersant in turn, under the power of 560w microwave, control the stirring rate to 350r / min, the temperature is 200 ℃, and react for 2 hours to prepare the nanocomposite material ;

[0058] (2) Take 20 parts of E51 bisphenol A epoxy resin and 13 parts of polypropylene by mass parts, add 5 parts of talcum powder, control the stirring rate at 160r / min, and the temperature at 150°C for 3 hours to prepare Obtain modified resin;

[0059] (3) Add 33 parts of nanocomposite materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com