Catalyst for synthesizing ethyl ethoxyacetate through hydrogenation of diethyl oxalate and preparation method and application of catalyst

A technology of ethyl ethoxyacetate and diethyl oxalate, which is applied to the catalyst for synthesizing ethyl ethoxyacetate by gas-phase hydrogenation of diethyl oxalate and the field of preparation thereof, and can solve the problem of overcapacity, single product, and limited development and industrialization. To achieve the effect of sufficient raw materials, simple preparation method and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

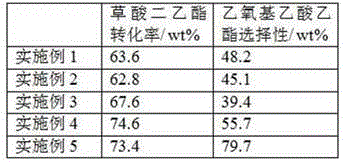

Examples

Embodiment 1

[0020] A method for preparing a catalyst for hydrogenating diethyl oxalate to synthesize ethyl ethoxy acetate, comprising the steps of: (1) uniformly mixing 0.223 g copper acetate and 3.422 g aluminum sulfate; (2) mixing copper ions and aluminum ions The total amount of ions and the molar coordination ratio of oxalic acid are calculated as 1:1.6. Add 4.41 g of oxalic acid to the mixed metal salt in the above step (1) and stir vigorously at room temperature for 6 h; (3) the obtained product in step (2) Move in 50 o C for 8 h, then at 100 o Dry at C for 5 h to obtain the catalyst precursor powder; raise the powder sample prepared in step (3) to 400 °C in air o Calcined at C for 10 h, heating rate 1 o C / min, that is, CuO / Al with a mass content of 5.0 wt% of copper oxide 2 o 3 Diethyl oxalate hydrogenation catalyst.

[0021] The above CuO / Al 2 o 3 1 mL of catalyst was filled in a fixed-bed tubular reactor. The catalyst was heated at a volumetric space velocity of 1800 h -...

Embodiment 2

[0023] A method for preparing a catalyst for hydrogenating diethyl oxalate to synthesize ethyl ethoxy acetate, comprising the following steps: (1) uniformly mixing 0.798 g copper sulfate and 5.009 g aluminum nitrate; (2) mixing copper ions and aluminum ions The total amount of ions and the molar coordination ratio of citric acid were calculated as 1:1.9, and 11.242 g of citric acid was quickly added to the mixed metal salt in the above step (1) and stirred vigorously at room temperature for 3 h; (3) the step (2 ) proceeds into 30 o C for 10 h, then at 80 o C and dried for 8 h to obtain the catalyst precursor powder; (4) heat the powder sample prepared in step (3) to 800 °C in air o Calcined at C for 1 h, heating rate 1 o C / min, that is, CuO / Al with a mass content of 25.0 wt% of copper oxide 2 o 3 Diethyl oxalate hydrogenation catalyst.

[0024] The above CuO / Al 2 o 3 1 mL of catalyst was filled in a fixed-bed tubular reactor. The catalyst was subjected to a volumetric ...

Embodiment 3

[0026]A method for preparing a catalyst for hydrogenating diethyl oxalate to synthesize ethyl ethoxy acetate, comprising the following steps: (1) uniformly mixing 1.876 g copper nitrate and 5.115 g aluminum nitrate; (2) mixing copper ions and aluminum ions The molar coordination ratio of the total amount of ions and tartaric acid is 1:1, and 6.904 g of tartaric acid is quickly added to the mixed metal salt in the above step (1) and vigorously stirred at room temperature for 4 h; (3) the obtained Item moved into 50 o C for 6 h, then at 70 o C for 10 h to obtain catalyst precursor powder; (4) heat the powder sample prepared in step (3) to 700 °C in air o C calcined for 2 h, heating rate 15 o C / min, that is, CuO / Al with a mass content of 40.0 wt% of copper oxide 2 o 3 Diethyl oxalate hydrogenation catalyst.

[0027] The above CuO / Al 2 o 3 1 mL of catalyst was filled in a fixed-bed tubular reactor. The catalyst was subjected to a volumetric space velocity of 3600 h -1 , 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com