Non-hydrogenated chocolate with cocoa butter alternatives and preparation method thereof

A non-hydrogenation, chocolate technology, applied in cocoa, confectionery, confectionary industry, etc., can solve the problems of poor taste, limited application, difficult operation, etc., and achieve the effect of overcoming the soft texture and meeting the quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Formula for producing 100kg non-hydrogenated cocoa butter substitute chocolate: non-hydrogenated refined palm kernel oil 28kg, non-hydrogenated coconut oil 10kg, white sugar 32kg, cocoa powder 8kg, skim milk powder 10kg, whey powder 2.5kg, maltodextrin 4.85kg, soybean protein Powder 1.8kg, glyceryl monostearate 2kg, soybean lecithin 0.4kg, polyglycerol ricinoleate 0.2kg, sucrose fatty acid ester 0.2kg, edible essence vanillin 0.05kg.

[0032] Preparation Process:

[0033] 1) Grind the white granulated sugar into powdered sugar with a sugar powder machine.

[0034] 2) Put non-hydrogenated vegetable oil, sucrose fatty acid ester, and glycerol monostearate together into an oil melting pot to melt them all to obtain an oil phase, and keep it at 70-90°C for later use.

[0035] 3) Mix powdered sugar, cocoa powder, milk powder, soybean protein powder, maltodextrin, and part of the oil, and then send it to a two-roller mill combined with a five-roller mill, and grind it to 15-...

Embodiment 2

[0042] Formula for producing 100kg non-hydrogenated cocoa butter substitute chocolate: non-hydrogenated refined palm kernel oil 25kg, non-hydrogenated coconut oil 12kg, white sugar 35kg, cocoa powder 7kg, skim milk powder 8kg, whey powder 4kg, maltodextrin 3.5kg, soybean protein powder 2kg, glyceryl monostearate 2.5kg, soybean lecithin 0.5kg, polyglycerol ricinoleate 0.2kg, sucrose fatty acid ester 0.2kg, food flavor vanillin 0.1kg.

[0043] Preparation Process:

[0044] 1) Grind the white granulated sugar into powdered sugar with a sugar powder machine.

[0045] 2) Put non-hydrogenated vegetable oil, sucrose fatty acid ester, and glycerol monostearate together into an oil melting pot to melt them all to obtain an oil phase, and keep it at 70-90°C for later use.

[0046] 3) Mix powdered sugar, cocoa powder, milk powder, soybean protein powder, maltodextrin, and part of the oil, and then send it to a two-roller mill combined with a five-roller mill, and grind it to 15-30 micro...

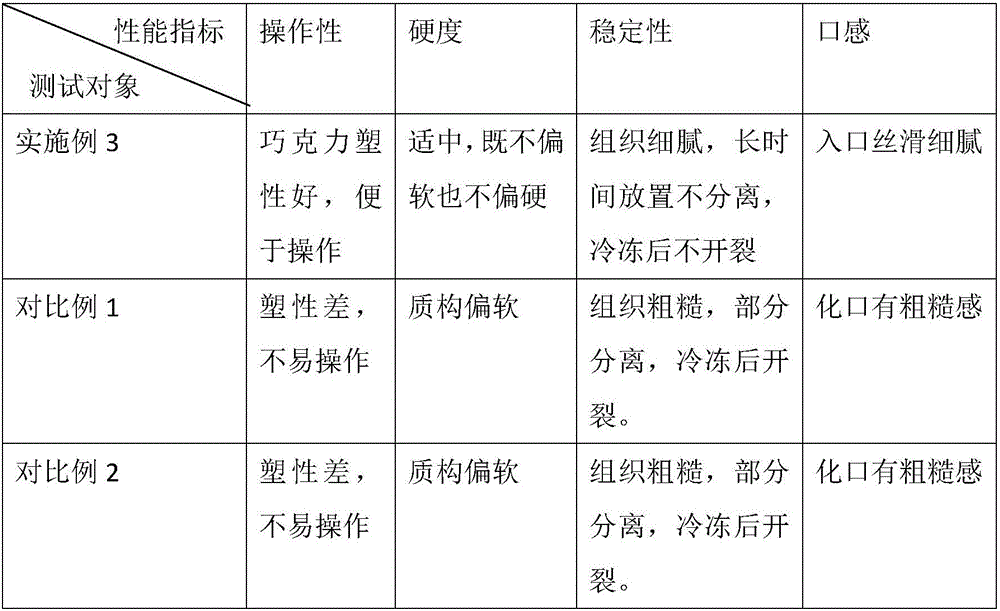

Embodiment 3

[0053]Formula for producing 100kg non-hydrogenated cocoa butter substitute chocolate: non-hydrogenated refined palm kernel oil 28kg, non-hydrogenated coconut oil 12kg, white sugar 30kg, cocoa powder 9kg, skim milk powder 7kg, whey powder 3kg, maltodextrin 5kg, soybean protein powder 2.6 kg, glyceryl monostearate 2.5kg, soybean lecithin 0.45kg, polyglycerol ricinoleate 0.2kg, sucrose fatty acid ester 0.2kg, food flavor vanillin 0.05kg.

[0054] Preparation Process:

[0055] 1) Grind the white granulated sugar into powdered sugar with a sugar powder machine.

[0056] 2) Put non-hydrogenated vegetable oil, sucrose fatty acid ester, and glycerol monostearate together into an oil melting pot to melt them all to obtain an oil phase, and keep it at 70-90°C for later use.

[0057] 3) Mix powdered sugar, cocoa powder, milk powder, soybean protein powder, maltodextrin, and part of the oil, and then send it to a two-roller mill combined with a five-roller mill, and grind it to 15-30 mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com