High capacity porous silicon material, preparation method and application thereof

A porous silicon, high-capacity technology, applied in the field of material science, can solve the problems of unfavorable high theoretical specific capacity, oxidation, and lower specific capacity of porous silicon, and achieve simple process, avoid oxidation, improve specific capacity and cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) The magnesium silicide is heat-treated at 600° C. for 20 hours, and excessive high-purity nitrogen is used as the reaction gas during the heat treatment.

[0027] 2) Treat the product obtained in step 1) in a hydrochloric acid solution of a certain concentration for 10 hours, where the concentration of hydrochloric acid is 0.5 mol / L, wash it with deionized water 5 times after acid treatment, then centrifuge, and finally vacuum dry.

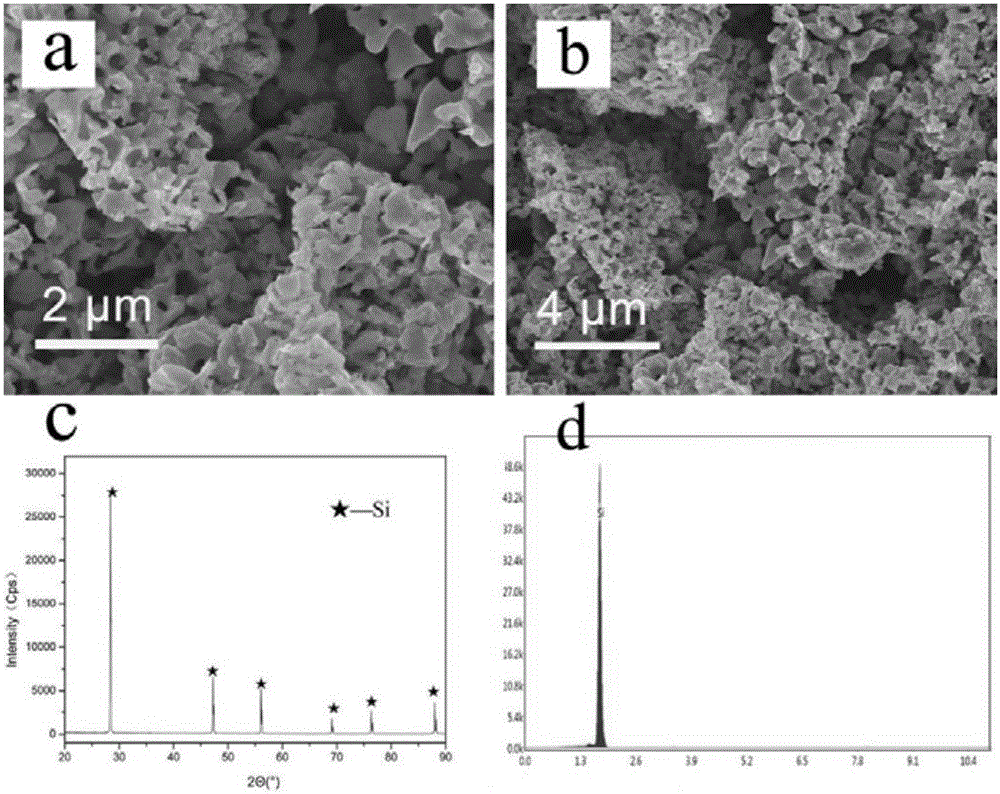

[0028] The relevant characterization results of the porous silicon prepared in this example are as follows figure 1 Shown. It can be seen from the figure that the particle size distribution of this porous silicon is narrow, the pore size is nanometer, the pore distribution is uniform, the particles are pure silicon, and the oxygen content is so low that the scanning electron microscope energy spectrometer (EDS) cannot detect oxygen.

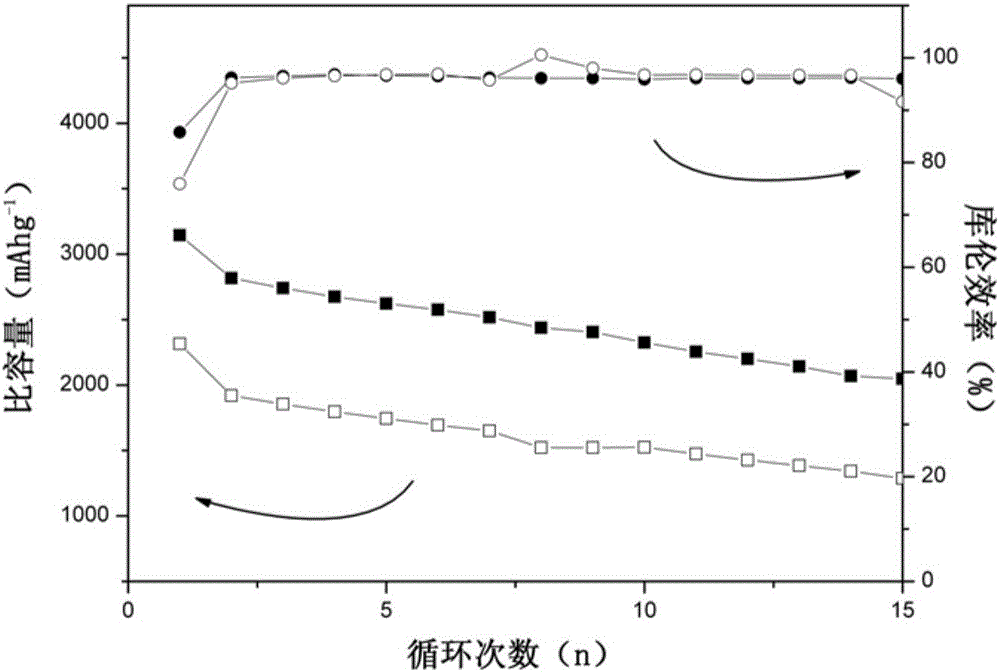

[0029] The porous silicon prepared in this example was made into a button cell for performance testing, and the...

Embodiment 2

[0031] 1) The magnesium silicide is heat-treated at 700° C. for 15 hours, and excessive high-purity nitrogen is used as the reaction gas during the heat treatment.

[0032] 2) Treat the product obtained in step 1) in a hydrochloric acid solution of a certain concentration for 5 hours, where the concentration of hydrochloric acid is 2.0 mol / L, wash it with deionized water 7 times after acid treatment, then centrifuge, and finally vacuum dry.

[0033] The relevant characterization results of the porous silicon material prepared in this example are the same as figure 1 similar.

[0034] The porous silicon prepared in the examples was made into a button cell for performance testing, and the cycle specific capacity curve and the coulombic efficiency were obtained as image 3 Shown. It can be seen from the figure that the porous silicon prepared by this process not only has a higher initial capacity, but after 15 cycles, its capacity is still much higher than that of ordinary porous silico...

Embodiment 3

[0036] 1) The magnesium silicide is heat-treated at 800° C. for 10 hours, and excessive high-purity nitrogen is used as the reaction gas during the heat treatment.

[0037] 2) Treat the product obtained in step 1) in a hydrochloric acid solution of a certain concentration for 2 hours, where the concentration of hydrochloric acid is 5 mol / L. After acid treatment, it is washed with deionized water 8 times, centrifuged, and finally vacuum dried.

[0038] The relevant characterization results of the porous silicon material prepared in this example are the same as figure 1 similar.

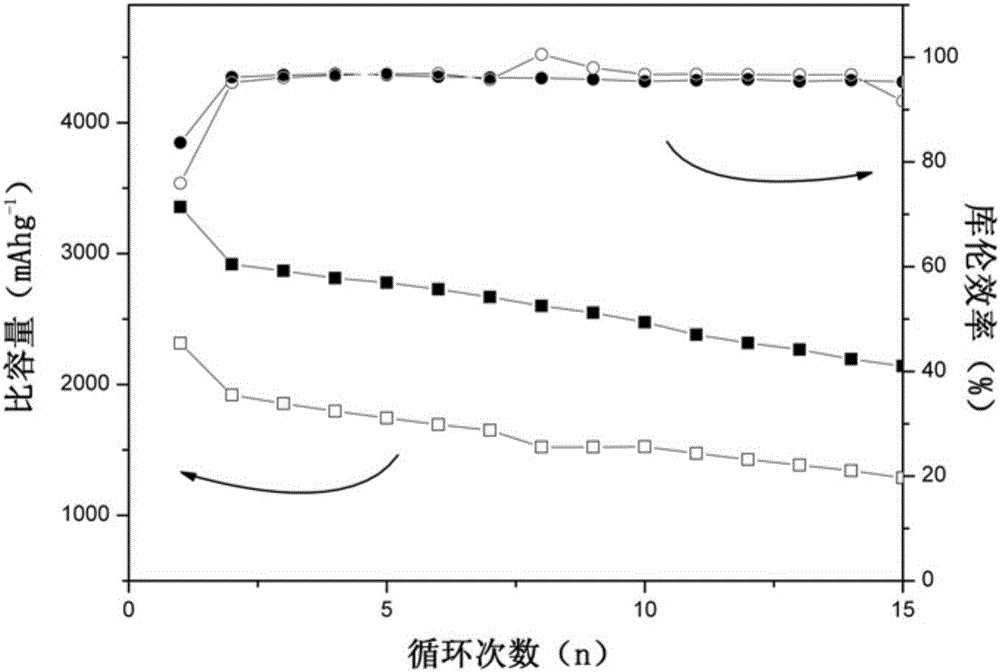

[0039] The porous silicon prepared in the examples was made into a button cell for performance testing, and the cycle specific capacity curve and the coulombic efficiency were obtained as Figure 4 Shown. It can be seen from the figure that the porous silicon prepared by this process not only has a higher initial capacity, but after 15 cycles, its capacity is still much higher than that of ordinary porous si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com