Enzyme solution, enzyme-containing nonwoven fabric, preparation method and application thereof

A technology of enzyme solution and non-woven fabric, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, and cleaning methods using tools, etc., and can solve problems such as affecting the success rate of pre-cleaning, decreasing the success rate of pre-cleaning, and poor enzyme stability. , to achieve the effect of good cleaning ability, good stability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

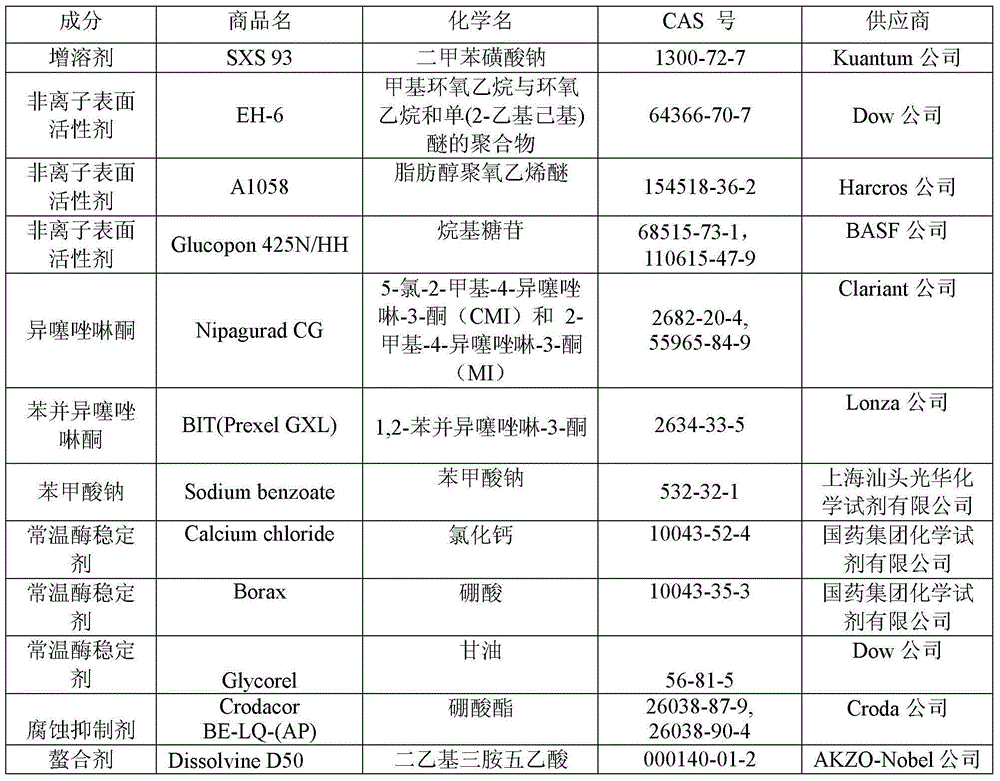

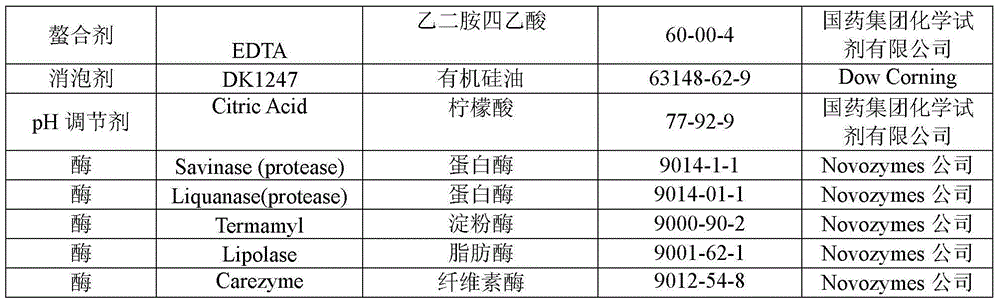

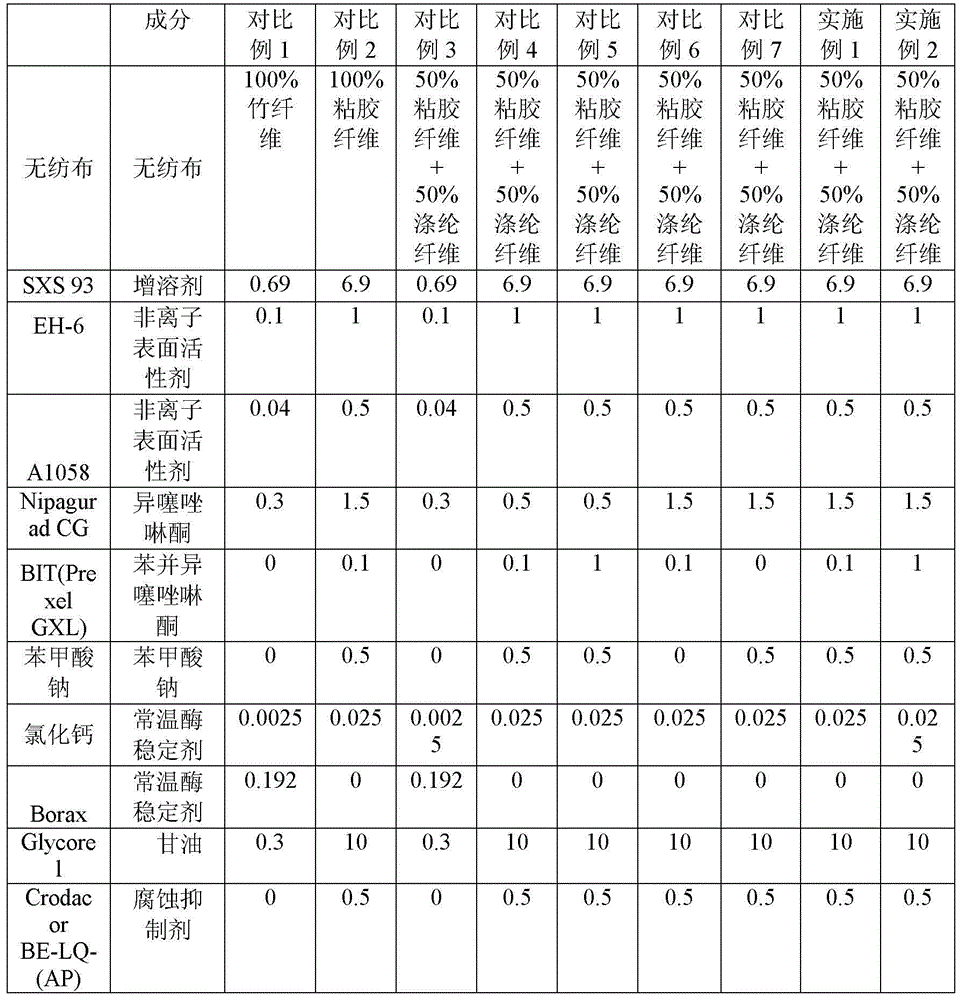

[0095] Specific embodiment 1 is an enzyme solution, based on the total weight of the enzyme solution by 100wt.%, including: 0.1-10wt.% nonionic surfactant; 0.01-1.2wt.% enzyme; 0.03-10.7 wt.% normal temperature enzyme stabilizer; 1-3wt.% isothiazolinone; 0.1-1wt.% benzisothiazolinone; 0.1-1wt.% sodium benzoate; 6.9-10wt.% solubilizer ; 0.15-0.5wt.% of pH regulator; and 63-81wt.% of water; the pH value of the enzyme solution is 6-10.

specific Embodiment approach 2

[0096] Embodiment 2 is an enzyme solution according to Embodiment 1, wherein the nonionic surfactant includes at least one component of the following group: (i) based on ethylene oxide, propylene oxide and A polymer of at least one of butylene oxide, (ii) alkyl glycoside, (iii) fatty alcohol ethoxylate, (iv) and ammonium oxide.

specific Embodiment approach 3

[0097] Embodiment 3 is an enzyme solution according to Embodiment 1 or 2, wherein the enzyme comprises at least one component in the following group: protease, amylase, lipase, and cellulase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com