A kind of preparation method of high magnetic permeability flaky soft magnetic alloy powder

A technology of soft magnetic alloy and high magnetic permeability, which is applied in the field of composite material manufacturing, can solve the problems of reduced yield, complicated production process, and insufficient flattening of magnetic powder, and achieves improved plastic deformation ability, high oxidation resistance, and effective Favorable effect on magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

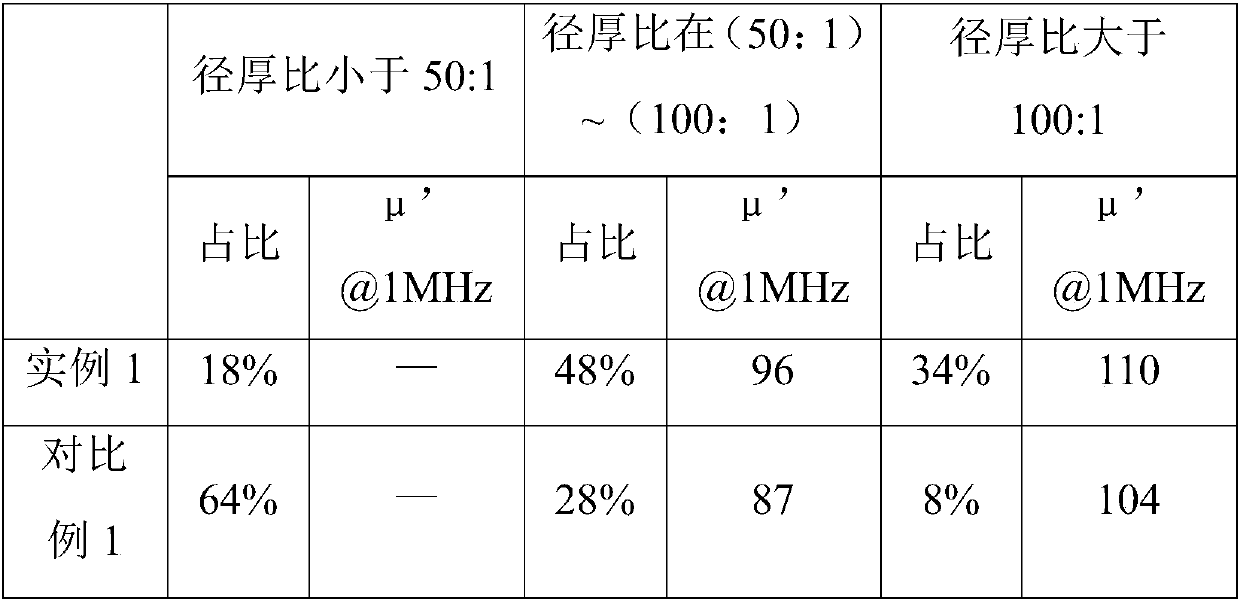

Embodiment 1

[0031] A preparation method of high magnetic permeability flaky soft magnetic alloy powder, comprising the following steps:

[0032] (1) Raw material selection: block Fe-Si-Al magnetic powder is selected as the raw material for ball milling, the particle size is 80-100 μm, the average particle size is 90 μm, and the solvent is absolute ethanol;

[0033] (2) Primary ball milling: Put the magnetic powder, solvent (absolute ethanol) and grinding balls in the step (1) into a sand mill for primary ball milling, the mass ratio of magnetic powder, absolute ethanol and grinding balls is 1:3 : 20, stainless steel balls with a diameter of 3 to 6 mm, the speed of the sand mill is 160 rpm, and the milling time is 6 hours. Put the magnetic powder in an oven for drying treatment at 80°C for 2 hours, the solvent evaporates completely.

[0034] (3) Primary reduction treatment: put the round cake-shaped magnetic powder in step (2) into a high-temperature annealing furnace for primary reductio...

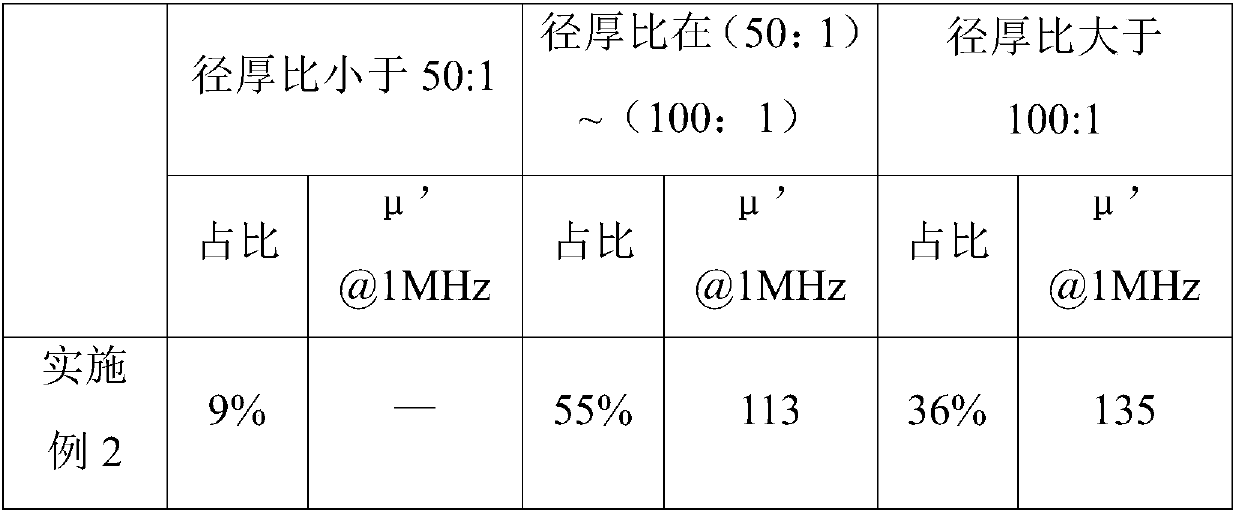

Embodiment 2

[0050] Step 1: Select block Fe-Ni-Mo magnetic powder as the raw material for ball milling, with a particle size of 20-80 μm and an average particle size of 40 μm.

[0051] Step 2: Put the magnetic powder, solvent (absolute ethanol) and grinding balls in step 1 into a planetary ball mill for primary ball milling. The mass ratio of magnetic powder, absolute ethanol and grinding balls is 1:2:10, and the diameter of the grinding balls is For stainless steel balls of 3-6 mm, the speed of the ball mill is 200 rpm, and the milling time is 2 hours. Put the magnetic powder into an oven for drying treatment at 100°C for 1.5 hours, and the solvent is completely evaporated.

[0052] Step 3: Put the round cake-shaped magnetic powder in step 2 into a high-temperature annealing furnace for primary reduction annealing. The annealing atmosphere is a mixture of hydrogen and argon. The annealing temperature is 400°C, the holding time is 60 minutes, and the pressure in the furnace is 0.2 MPa;

...

Embodiment 3

[0061] Step 1: select spherical Fe-Ni magnetic powder as the raw material for ball milling, with a particle size of 80-150 μm and an average particle size of 120 μm.

[0062] Step 2: Put the magnetic powder, solvent (absolute ethanol) and grinding balls in step 1 into a planetary ball mill for primary ball milling. The mass ratio of magnetic powder, absolute ethanol and grinding balls is 1:4:30, and the diameter of the grinding balls is For stainless steel balls of 3-6 mm, the speed of the ball mill is 250 rpm, and the milling time is 1 hour. Put the magnetic powder into an oven for drying treatment, the drying temperature is 90°C, and the drying time is 1.5 hours, and the solvent is completely evaporated.

[0063] Step 3: Put the round cake-shaped magnetic powder in step 2 into a high-temperature annealing furnace for primary reduction annealing treatment. The annealing atmosphere is a mixture of hydrogen and argon. The annealing temperature is 800°C, and the holding time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com