Method for preparing sintering-free self heat preservation brick from sludge, mineralized refuse and building waste

A technology for mineralizing garbage and construction waste, which is applied in the field of solid waste resource utilization, and can solve the technical difficulty of sintering bricks and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for preparing non-sintering self-insulating bricks by using sludge, mineralized waste and construction waste specifically includes the following steps:

[0046] 1) Pretreatment: Take 90 parts by weight of modified sludge and 3 parts by weight of sea shell ash, and use sludge pump and powder pump to send to the sludge dryer, mix evenly, and then dehydrate and dry to make the dehydration rate of the sludge Reach 90%, repeat grinding and pass through 80 mesh sieve to get activated sludge;

[0047] 2) Wheel grinding: 100 parts by weight of activated sludge, 12 parts by weight of sea shell ash, 30 parts by weight of fly ash, 50 parts by weight of mineralized waste, 34 parts by weight of construction waste, and 15 parts by weight of clay , 5 parts by weight of the F14 activator and 30 parts by weight of water are input to the XLH-800 planetary wheel mill mixer for wheel milling and mixing, and the wheel milling time is 2min to become a mixture;

[0048] 3) Digesti...

Embodiment 2

[0056] The method for preparing non-sintering self-insulating bricks by using sludge, mineralized waste and construction waste specifically includes the following steps:

[0057] 1) Raw material preparation:

[0058] ① The sludge is taken from the sludge dehydration workshop of the local sewage treatment plant. The dehydration process mainly adopts the addition of CaO and FeCl 3 After stabilization, plate frame filter press is carried out, and the moisture content is controlled at 45%;

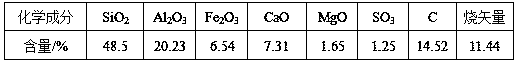

[0059] ② Fly ash is collected from the flue gas after coal combustion in local thermal power plants. It is dark brown and its chemical composition is shown in Table 1. The specific surface area of fly ash reaches 486m 2 / kg, the density is 2.4g / cm 3 , the main mineral composition is SiO 2 (content 48.5%), Al 2 o 3 (content 20.23%) and CaO (content 7.31%);

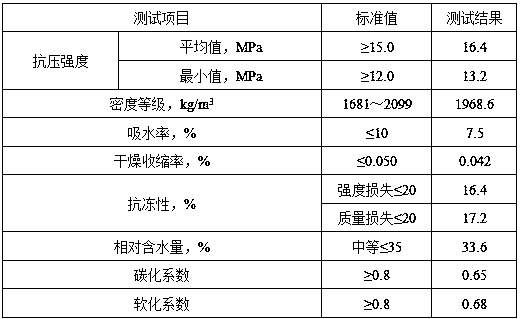

[0060]③ The clay is taken from the surface soil of the local area. It is dried, ball milled and sieved before use. The particle s...

Embodiment 3

[0079] The method for preparing sinter-free self-insulating bricks from sludge, mineralized waste and construction waste includes: pretreatment, rolling, digestion, secondary rolling, molding, and maintenance, specifically including the following steps:

[0080] Pretreatment: Take 95 parts by weight of modified sludge and 5 parts by weight of sea shell ash, and use sludge pump and powder pump to send to the sludge dryer, mix evenly, and then dehydrate and dry, so that the dehydration rate of the sludge reaches 94% %, repeated grinding and passing through a 100-mesh sieve to obtain activated sludge; the mutual cooperation of various raw materials can remove the odor of the sludge, adjust the sludge to be neutral, and increase the calcium content in the sludge to promote sea shell ash Hydration progress, stimulate sludge activity;

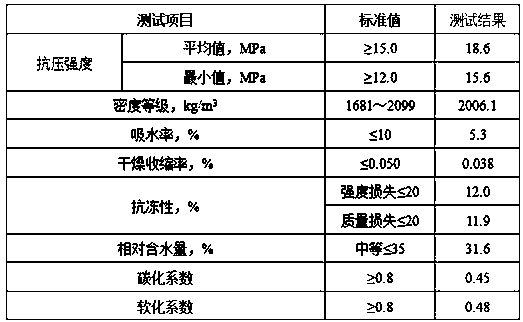

[0081] Wheel grinding: the activated sludge of 110 parts by weight, the sea shell ash of 15 parts by weight, the fly ash of 45 parts by weight, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com