Manufacturing method of optical film, optical device, display substrate, and display device

A production method and optical film technology, applied in optical elements, chemical instruments and methods, optics, etc., can solve the problems of large loss of light efficiency of OLED display devices, improve light output efficiency and spectral stability, improve display brightness, Improve the effect of refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for manufacturing an optical film, the optical film is used to refract light, and the method includes:

[0047] An uneven structure is formed on the surface of the optical film.

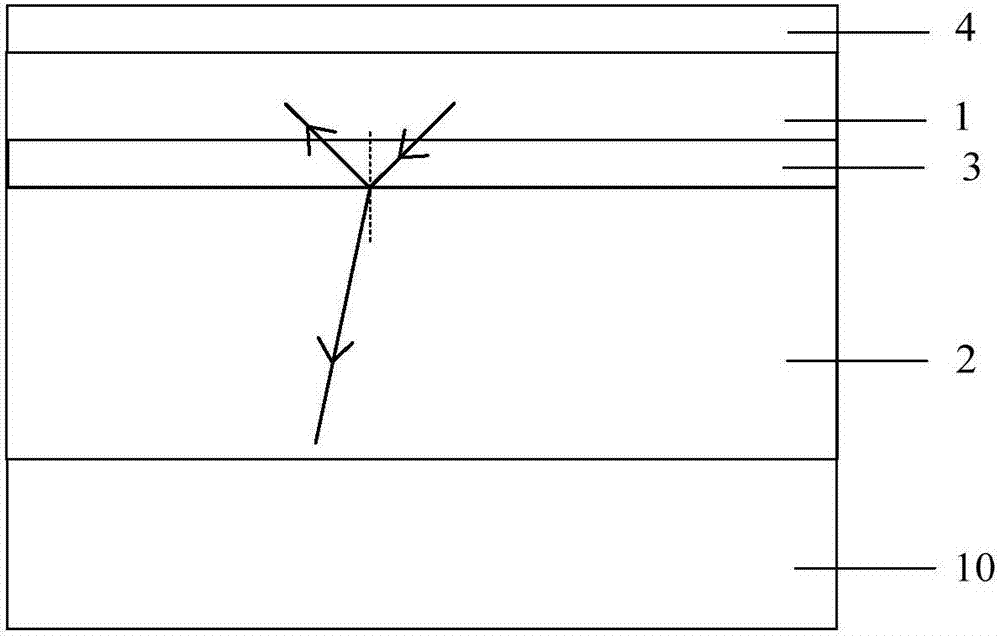

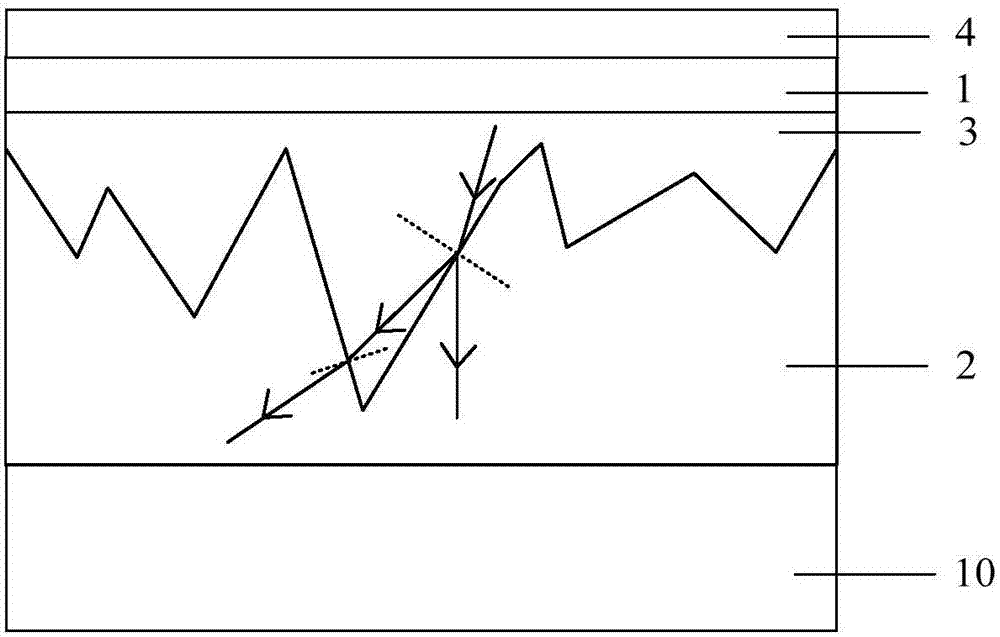

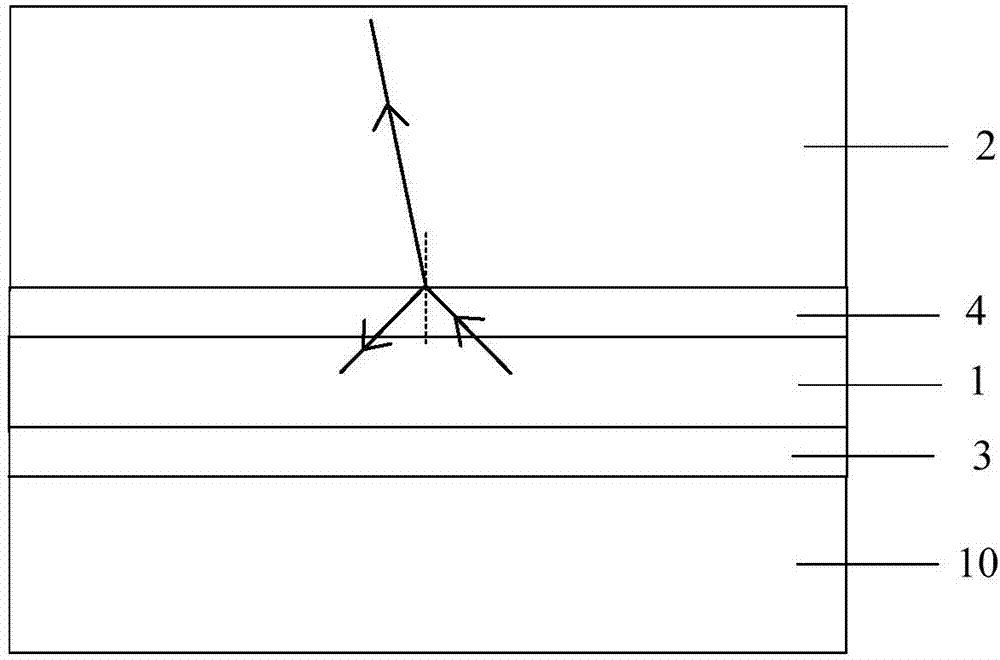

[0048] The optical film formed through the above steps has an uneven structure on its surface, which can improve the refraction of light, increase the transmittance and spectral stability of light, and refer to the specific principle figure 2 and Figure 4 As shown, the straight line with the arrow in the figure indicates the optical path. The protrusions and depressions of the uneven structure can change the optical path and increase the refraction effect. When applied to a display device, it can improve the display brightness of the product, reduce power consumption, and increase the viewing angle so that the display product is not affected by the viewing angle.

[0049] It should be noted that the surface of the film mentioned in this embodiment refers t...

Embodiment 2

[0087] Based on the same inventive concept, combining figure 1 and image 3 As shown, this embodiment provides an optical device, including a light-emitting device and an optical film 2 manufactured by the manufacturing method in Embodiment 1. The optical film 2 is used to refract the light emitted by the light-emitting device.

[0088] The above-mentioned optical device can refract light to the light-emitting side through the optical film, and can improve light output efficiency and spectral stability. When applied to a display device, it can also improve the display brightness of the product and reduce power consumption.

[0089] The light-emitting device may be a light-emitting device such as an organic light-emitting diode, a quantum dot light-emitting diode, or the like.

[0090] Taking an organic light emitting diode as an example, the light emitting device includes a light emitting layer 1 , an optical film 2 is closer to the light emitting side of the light emitting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com