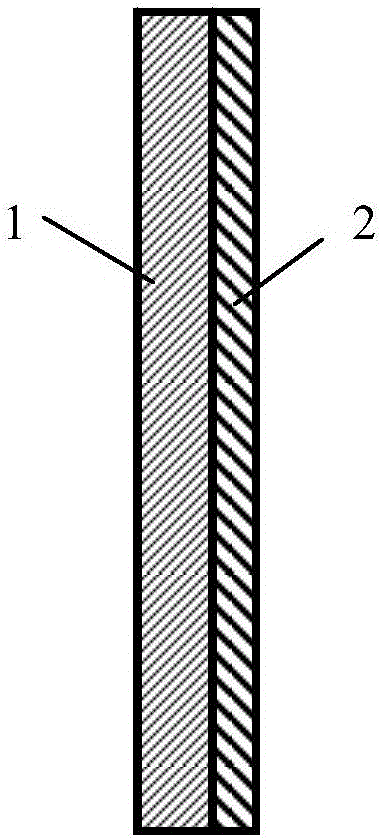

Single-sheet type bipolar membrane and preparation method thereof

A bipolar membrane and monolithic technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of low chemical stability and thermal stability of functional groups, reduce operation steps, limit the scope of use, etc. Achieve good thermal stability and chemical stability, good thermal stability and chemical stability, save the effect of film forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Clean the basement membrane (ethylene-tetrafluoroethylene copolymer film) and put it in a vacuum drying oven to dry to constant weight, then put the basement membrane into an irradiation bottle and put it in a cobalt source irradiation chamber for irradiation To a total dose of 100kGy.

[0048] (2) The irradiated membrane is placed in the reactor, so that one side of the membrane is soaked in the positive grafted monomer solution, and the other side is soaked in the negative grafted monomer solution, and the membrane separates the two monomers Open it, blow nitrogen into the reactor to remove the air in the reactor, then seal it, put the reactor into a constant temperature water bath at 60°C for 2 hours, so that the two sides of the membrane are grafted with different monomers. The grafting monomer solution on the positive side is a toluene solution of 30% styrene; the grafting monomer solution on the negative side is an aqueous solution of 85% vinylimidazole. Afte...

Embodiment 2

[0057] (1) Clean the basement membrane (polyvinylidene fluoride film) and put it in a vacuum drying oven to dry to constant weight, then put the basement membrane into an irradiation bottle, and put it into a cobalt source irradiation chamber to irradiate to the total dose is 100kGy.

[0058] (2) The film after irradiation is placed in the reactor, one side of the film is soaked in the positive grafting monomer solution, the other side is not soaked in the solution, and nitrogen gas is fed to get rid of the air in the reactor, and then sealed, The reactor was placed in a constant temperature water bath at 80°C to react for 1 hour, and the positive side grafting reaction was carried out on one side of the membrane. The positive side grafting monomer solution is 30% styrene in toluene solution. After the reaction, remove the residual monomer solution and homopolymer in the film, and dry it for future use.

[0059](3) Put the film into an irradiation bottle again, and put it in...

Embodiment 3

[0066] (1) Clean the basement film (polyethylene film) and put it in a vacuum drying oven to dry to constant weight, then put the basement film into an irradiation bottle, and put it into a cobalt source irradiation room to irradiate to a total dose of 20kGy .

[0067] (2) The irradiated membrane is placed in the reactor, so that one side of the membrane is soaked in the positive grafted monomer solution, and the other side is soaked in the negative grafted monomer solution, and the membrane separates the two monomers After opening, nitrogen gas was introduced to remove the air in the reactor, and then sealed, and the reactor was placed in a 40°C constant temperature water bath to react for 24 hours, so that the two sides of the membrane were grafted with different monomers. The grafting monomer solution on the positive side is a toluene solution of 30% p-methylstyrene; the grafting monomer solution on the negative side is an aqueous solution of 60% allyl alkenylimidazole. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Cation exchange capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com