A preparing method of a lotus seed amylase-aliphatic acid composite having a high composite index number

A lotus seed amylose and composite index technology, applied in the direction of food science, etc., can solve the problems of inability to adapt to industrialized continuous production, long production time, cumbersome process, etc., achieve good transportation and protection, improve the composite probability, and increase the composite probability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of lotus seed amylose-fatty acid compound with high composite index, concrete steps are:

[0036] (1) Preparation of lotus seed amylose: use n-butanol crystallization method to prepare lotus seed amylose;

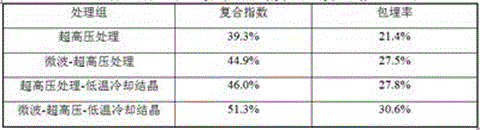

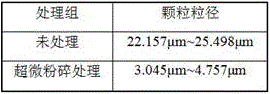

[0037] (2) Superfine pulverization: transfer the lotus seed amylose prepared in step (1) into a superfine pulverizer for processing, use a cooling device to control the temperature at 29°C, and process for 30 minutes to collect submicron lotus seed amylose And use MalvernMastersizer 2000 laser particle size analyzer to measure particle size;

[0038] (3) Fatty acid pretreatment: Mix linoleic acid with 35% (v / v) alcohol solution to prepare a 3wt% fatty acid solution, stir until the particles are evenly dispersed, and use ultrasonic equipment (200 W) for 8 minutes;

[0039] (4) Microwave treatment: the submicron lotus seed amylose obtained in step (2) was prepared with water to make 5wt% starch paste, and an equal volume of linoleic acid s...

Embodiment 2

[0047] A kind of preparation method of lotus seed amylose-fatty acid compound with high composite index, concrete steps are:

[0048] (1) Preparation of lotus seed amylose: use n-butanol crystallization method to prepare lotus seed amylose;

[0049] (2) Ultrafine pulverization: transfer the amylose prepared in step (1) into an ultrafine pulverizer for processing, use a cooling device to control the temperature at 32°C, and process for 28 minutes, collect submicron amylose from lotus seeds and Use MalvernMastersizer 2000 laser particle size analyzer to measure particle size;

[0050] (3) Fatty acid pretreatment: Mix linoleic acid with 40% (v / v) alcohol solution to prepare a 3wt% fatty acid solution, stir until the particles are evenly dispersed, and use ultrasonic equipment (250 W) for 10 minutes;

[0051] (4) Microwave treatment: the submicron lotus seed amylose obtained in step (2) was prepared with water to make 8wt% starch paste, and an equal volume of linoleic acid soluti...

Embodiment 3

[0059] A kind of preparation method of lotus seed amylose-fatty acid compound with high composite index, concrete steps are:

[0060] (1) Preparation of lotus seed amylose: use n-butanol crystallization method to prepare lotus seed amylose;

[0061] (2) Superfine pulverization: transfer the lotus seed amylose prepared in step (1) into a superfine pulverizer for processing, use a cooling device to control the temperature at 30°C, and process for 29 minutes to collect submicron lotus seed amylose And use MalvernMastersizer 2000 laser particle size analyzer to measure particle size;

[0062] (3) Fatty acid pretreatment: Mix linolenic acid with 36% (v / v) alcohol solution to prepare a 5wt% fatty acid solution, stir until the particles are evenly dispersed, and use ultrasonic equipment (250 W) for 10 minutes;

[0063] (4) Microwave treatment: the submicron lotus seed amylose obtained in step (2) was prepared with water to make 8wt% starch paste, and an equal volume of linolenic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com