Phosphorus-based grouting filling material suitable for old goaf treatment

A technology of filling materials and gobs, which is applied in the field of preparation of high-aluminum-content non-alkali and chlorine-free accelerators, can solve problems such as unsuitable for long-distance pumping, high cement cost, low filling efficiency, etc., and achieve rapid strength development , high waste rate and high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

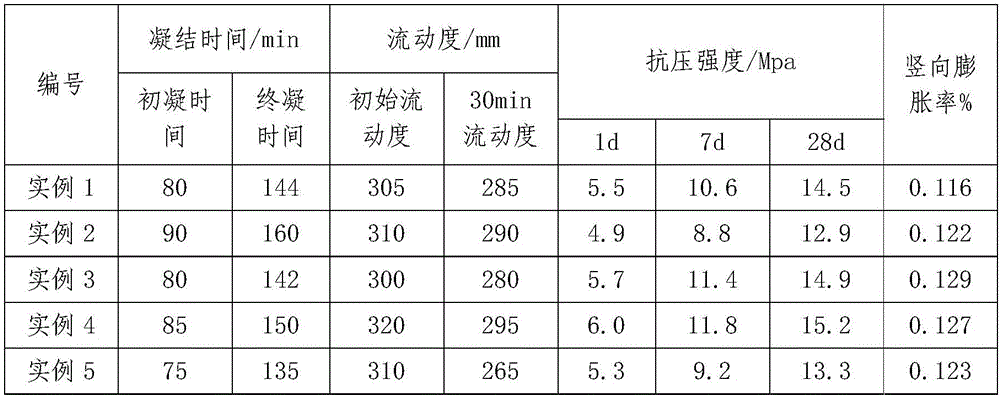

Examples

Embodiment 1

[0022] Embodiment 1: Mix 40 parts of phosphorus slag powder, 30 parts of fly ash, 5 parts of industrial waste slag carbide slag, 1 part of sodium nitrite, and 3 parts of calcium sulfoaluminate expansion agent in parts by weight, and mix the mixture with 1.5 parts Add melamine-based water reducer, 0.5 parts of carboxymethyl cellulose ether, and 30 parts of water into the mixing tank, stir evenly, add 100 parts of phosphorus tailings and stir evenly again to obtain phosphorus-based grouting filling materials.

[0023] The phosphorus slag powder is obtained by grinding and sieving the industrial waste residue when preparing yellow phosphorus by the electric furnace method of phosphorus chemical industry. Its quality coefficient K value is ≥ 1.1, and the specific surface area is ≥ 350m 2 / kg, P 2 o 5 Content ≤ 3.5%, chloride ion content ≤ 0.06%.

[0024] The fly ash is any one of primary fly ash and secondary fly ash.

[0025] The phosphorous tailings are fine-grained tailings ...

Embodiment 2

[0026] Embodiment 2: with embodiment 1, the difference is,

[0027] Mix 60 parts of phosphorus slag powder, 40 parts of fly ash, 7 parts of calcium carbide slag, 3 parts of sodium nitrite, 6 parts of calcium sulfoaluminate-calcium oxide expansion agent in parts by weight, and mix the mixture with 1.5 parts of melamine Water agent, 1 part of hydroxypropyl methylcellulose ether, and 50 parts of water are added to the stirring tank, and after stirring evenly, 200 parts of phosphorus tailings are added and stirred evenly again to obtain the phosphorus-based grouting filling material.

Embodiment 3

[0028] Embodiment 3: with embodiment 1, the difference is,

[0029] Mix 60 parts of phosphorus slag powder, 30 parts of fly ash, 6 parts of calcium carbide slag, 4 parts of sodium nitrite, and 8 parts of calcium sulfoaluminate expansion agent in parts by weight, and mix the mixture with 0.5 parts of polycarboxylic acid water-reducing agent. Add 0.5 parts of starch ether and 40 parts of water into the mixing tank, stir well, add 130 parts of phosphorus tailings and stir evenly again to obtain phosphorus-based grouting filling material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com