Preparation method for bismuth telluride quantum point

A technology of bismuth telluride and quantum dots is applied in the field of preparation of bismuth telluride quantum dots and bismuth telluride quantum dots, which can solve the problems of high cost and complicated process, achieve high yield, good application prospect and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

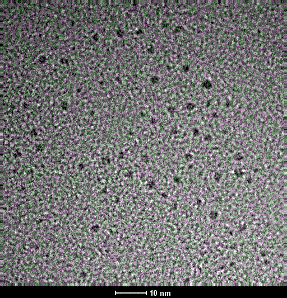

Image

Examples

Embodiment Construction

[0016] Weigh 0.5 g of bismuth telluride powder with a balance, place it in an agate mortar and grind it thoroughly, transfer the ground powder to a beaker, add 50 ml of nitrogen-methylpyrrolidone (NMP), and place it in an ultrasonic instrument for cumulative ultrasonication for 4 hours. After sonication, transfer the suspension to a centrifuge for centrifugation. After centrifugation, the supernatant liquid can be collected to obtain bismuth telluride quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com