Pressure detection device

A detection device and pressure technology, applied in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of expensive accuracy, unfavorable marketization, and not high enough of pressure transmitters, achieve reliable oil well production operations, and ensure accuracy and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

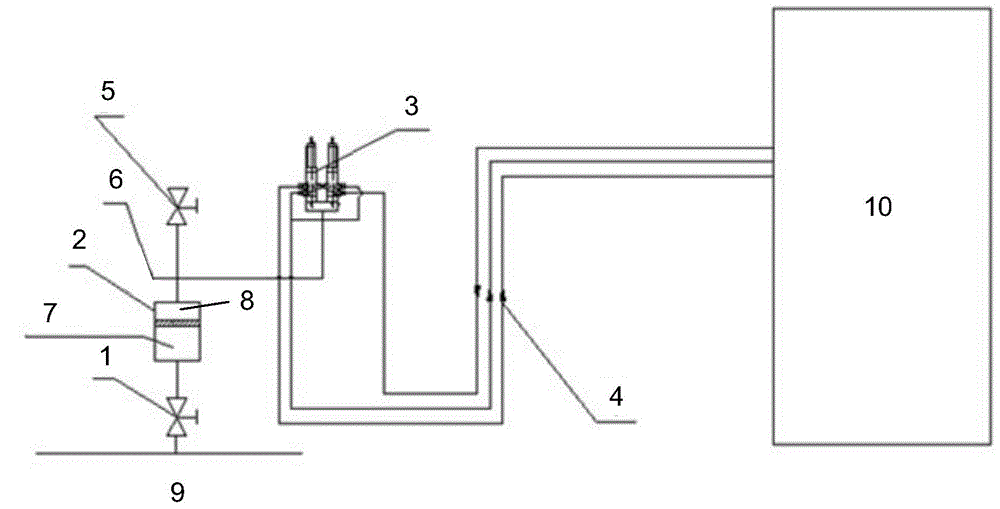

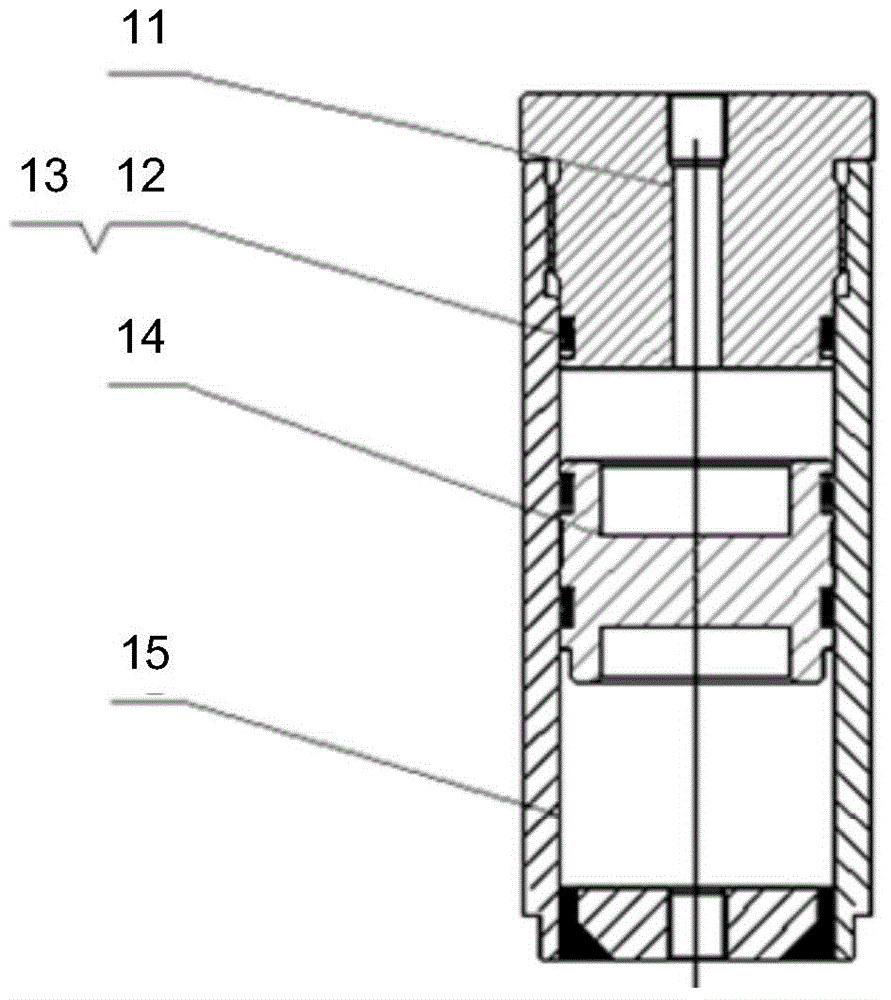

[0026] Instead of traditional pressure detectors that are directly arranged in the pipeline or directly contact with the working medium in the pipeline in any way, for example, can be configured as pilot valves or pressure transmitters, the present invention combines such pressure detectors 3 with the production pipeline At least one pressure transmitter 2 is arranged between 9.

[0027] The pressure transmitter 2 can be in direct flow communication with the working medium (not further shown), such as gas, in the production pipeline when necessary, so as to effectively transmit the pressure of the working medium in the production pipeline to the A pressure detector 3 located downstream of the pressure transmitter 2 (for example, it can also be a conventional high and low pressure pilot valve or similar device).

[0028] Preferably, the pressure transmitter can hydraulically transmit the pressure to the downstream pressure detector 3 (or it can be called the hydraulic pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com