Automatic strip steel welding device

An automatic welding and strip steel technology, applied in welding equipment, welding accessories, electrode support devices, etc., can solve problems such as danger, harsh working environment, and reduced production efficiency, and achieve simple processing, low cost, and improved quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing

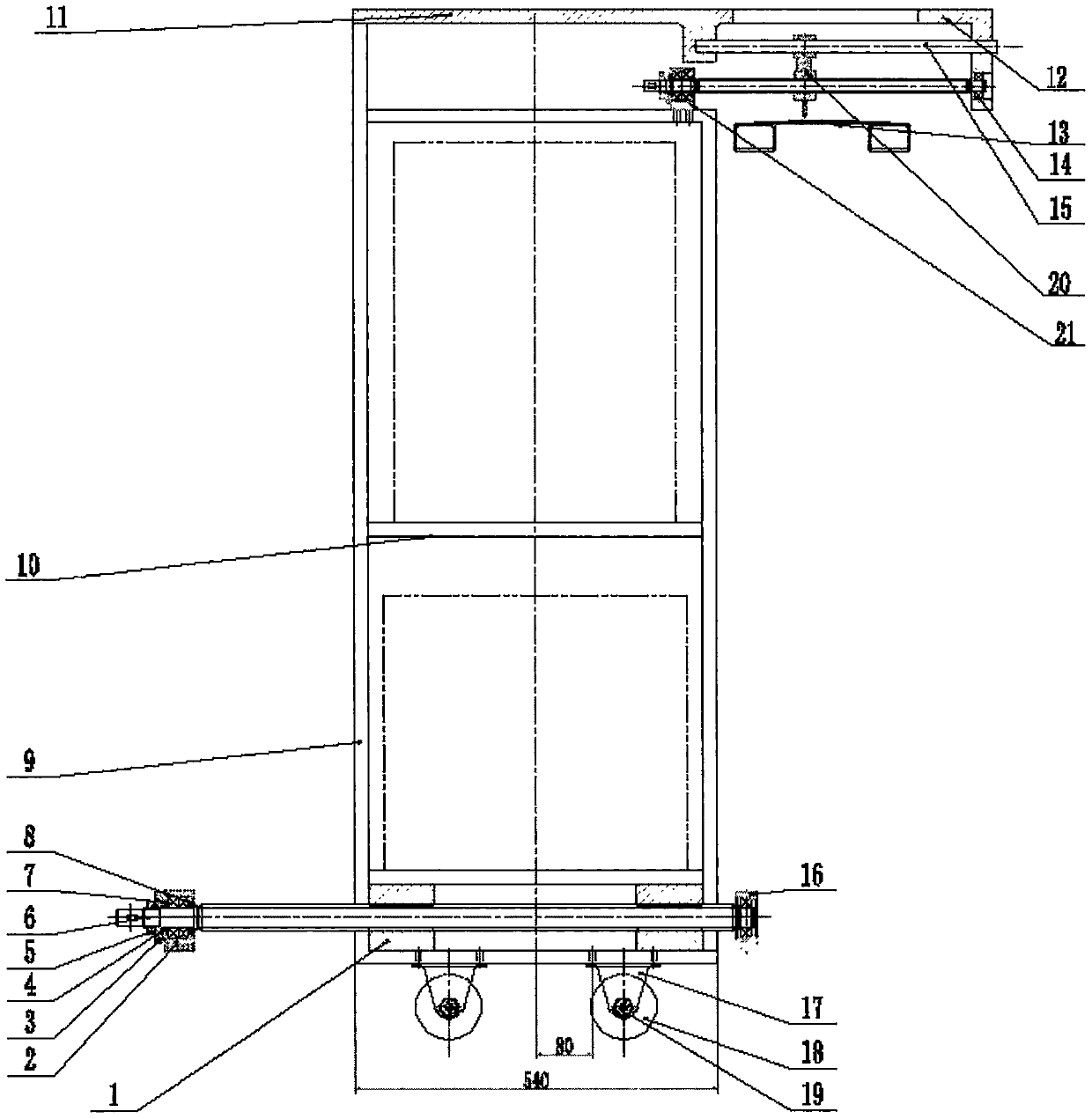

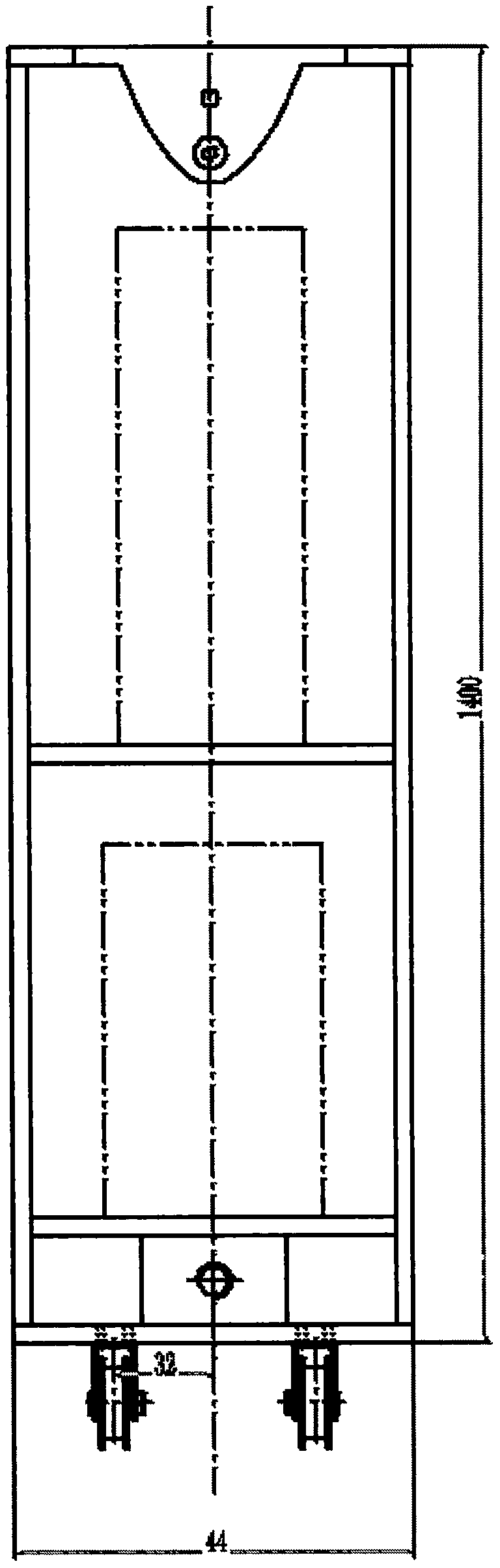

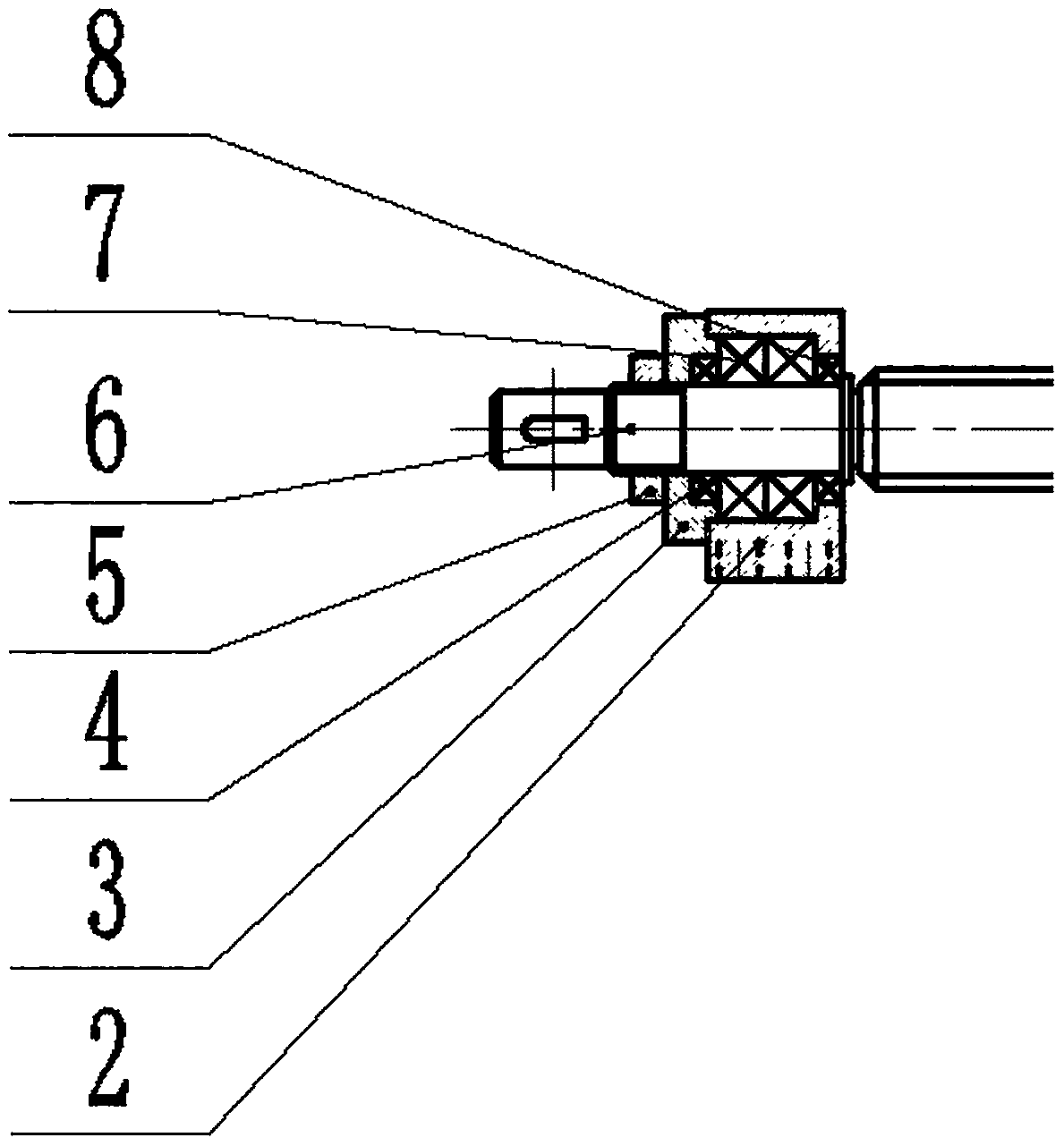

[0022] figure 1 The general assembly structure of the present invention is a schematic diagram, and a kind of strip steel automatic welding device proposed by the present invention mainly consists of main drive screw 6, welder frame 9, welding head feed screw, bearing block, roller 18, track, The bracket with guide rod 12, the welding head bracket 20, the control system, the welding machine system and the power system are composed of; the main drive screw 6 is connected to the welding machine frame 9 through two sets of screw pairs 1 embedded in the welding machine frame 9 , one end of the main drive screw 6 extends out of the head and is fixed in the bearing seat, the other end is connected with the reduction box, the reduction box is connected with the stepping motor, and the speed and stop of the stepping motor are controlled by the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com