Amorphous alloy reinforced aluminum matrix composite and preparation method thereof

A technology of aluminum-based composite materials and amorphous alloys, which is applied in the field of composite material preparation, can solve problems such as interface peeling, adverse interface reactions, and decreased mechanical properties of composite materials, and achieve good interface state, good density and good mechanical properties , the effect of increasing density and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

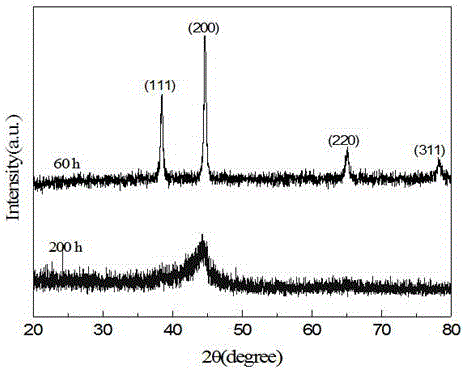

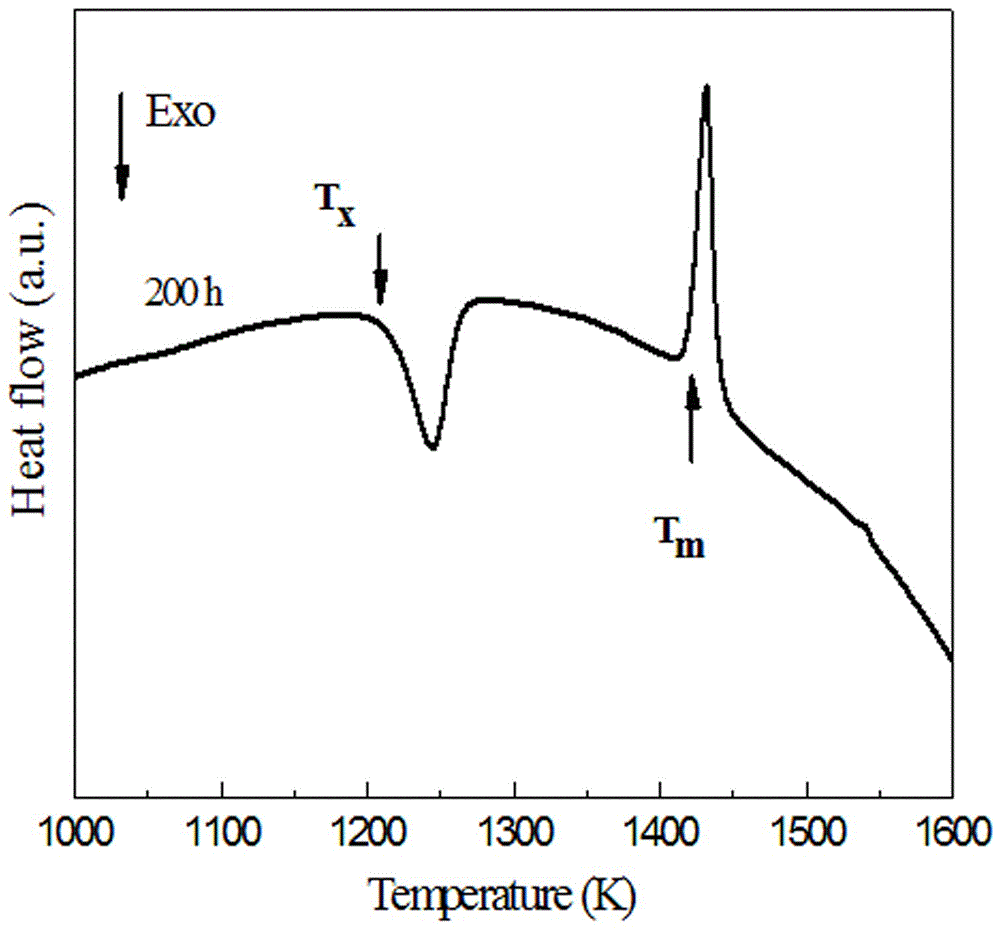

[0044] (1) Preparation of amorphous alloy powder: weigh the Al powder and Fe powder with a purity of ≧99.9 according to the atomic percentage of 85:15, put them in a ball mill jar, add stearic acid as a protective agent, vacuumize the ball mill jar, and fill it with argon , and then mechanically alloyed for 200h at a speed of 350rpm and a ball-to-material ratio of 15:1 to obtain Al 85 Fe 15 Amorphous alloy powder; the XRD pattern of amorphous alloy is shown in figure 1 , it can be seen from the figure that the amorphous phase has appeared after 200 hours. The crystallization temperature diagram of amorphous alloy is shown in figure 2 , as can be seen from the figure, its initial crystallization temperature is 1209K.

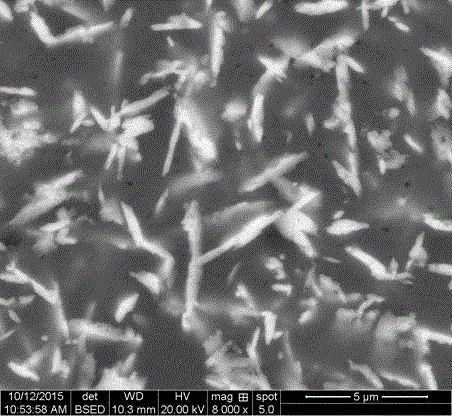

[0045] (2) Powder mixing: Al 85 Fe 15 Amorphous alloy powder and grade 2024 aluminum alloy powder are put into ball milling tank according to the volume ratio of 1:4. The ball milling tank is evacuated and filled with argon, and then ball milled and mixed f...

Embodiment 2

[0048] (1) Preparation of amorphous alloy powder: weigh the Al powder and Fe powder with a purity of ≧99.9 according to the atomic percentage of 85:15, put them in a ball mill jar, add stearic acid as a protective agent, vacuumize the ball mill jar, and fill it with argon , and then mechanically alloyed for 160h at a speed of 400rpm and a ball-to-material ratio of 15:1 to obtain Al 85 Fe 15 Amorphous alloy powder, its XRD pattern and figure 1 Similarly, the initial crystallization temperature is 1207K;

[0049] (2) Powder mixing: Al 85 Fe 15 Amorphous alloy powder and aluminum alloy powder of grade 6061 are put into ball milling tank according to the volume ratio of 2:3, the ball milling tank is evacuated and filled with argon, and then the powder is mixed for 10 hours under the conditions of rotating speed 350rpm and ball-to-material ratio 15:1. get mixed material;

[0050] (3) Vacuum hot-press sintering: put the mixed material into a cylindrical graphite abrasive tool w...

Embodiment 3

[0052] (1) Preparation of amorphous alloy powder: Weigh the Al powder and Fe powder with a purity of ≧99.9 according to the atomic percentage of 85:15, put them in a ball mill jar, add a protective agent, vacuumize the ball mill jar, fill it with argon, and then 350rpm, mechanical alloying for 180h under the condition of ball-to-material ratio 20:1, to obtain Al 85 Fe 15 Amorphous alloy powder, its XRD pattern and figure 1 Similarly, the initial crystallization temperature is 1209K;

[0053] (2) Powder mixing: Al 85 Fe 15 Amorphous alloy powder and aluminum alloy powder of grade 6061 are put into a ball mill tank according to the volume ratio of 3:7, the ball mill tank is evacuated and filled with argon, and then the powder is mixed for 10 hours at a speed of 350 rpm and a ball-to-material ratio of 20:1. get mixed material;

[0054] (3) Vacuum hot pressing sintering: put the mixture into a cylindrical graphite abrasive tool with a diameter of 45mm, put it in a vacuum hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com