Intercalated structure nano material with room-temperature long-afterglow luminescence property and preparation method thereof

A technology of long-lasting luminescence and nano-materials, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as short service life, expensive raw materials, and irregular microscopic appearance of products, and achieve long-lasting afterglow effect and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 0.83 g of isophthalic acid and 0.40 g of sodium hydroxide in 100 ml of deionized water, and dissolve 1.88 g of aluminum nitrate nonahydrate and 2.97 g of zinc nitrate hexahydrate in 100 ml of deionized water. The two solutions were combined and stirred at 60°C for 24 hours. The white colloid solution after the reaction was centrifuged three times at 3500r / min, and then dried at 60°C for 24h.

[0021] To characterize the product,

[0022] The PXRD test of the product powder showed that the generated isophthalic acid intercalated hydrotalcite composite had reliable phase purity, and the organic molecules of isophthalic acid were successfully intercalated between the hydrotalcite layers. It provides a guarantee for its application as a room temperature phosphorescent material.

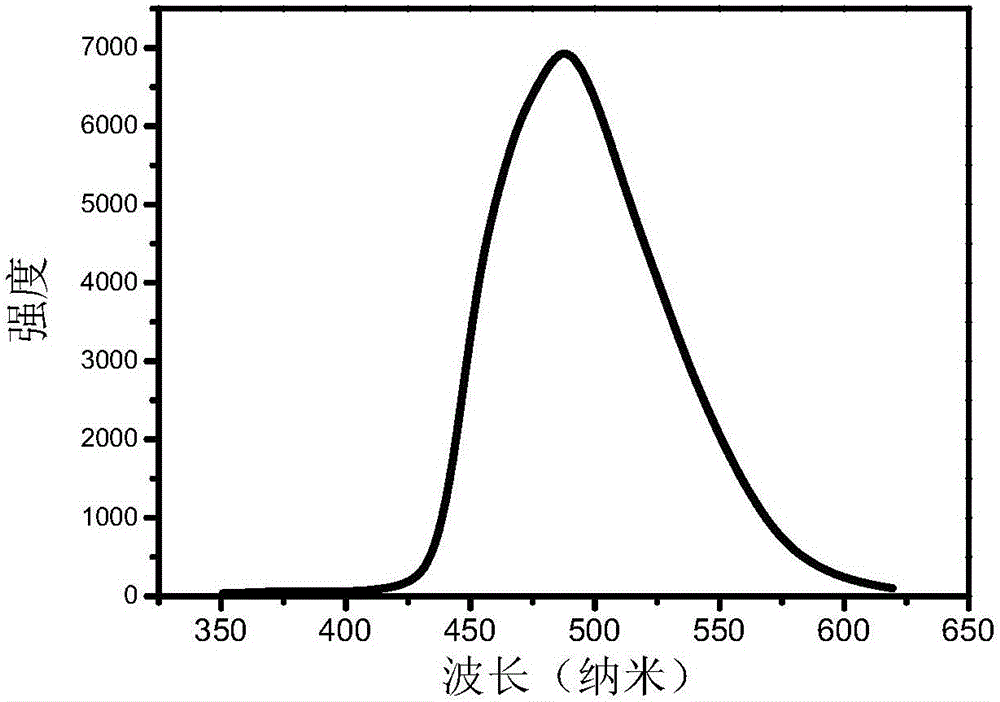

[0023] From the phosphorescence analysis, it can be seen that when excited at 320 nanometers, the phosphorescence emission peak of the isophthalic acid intercalated hydrotalcite composit...

Embodiment 2

[0026] Dissolve 0.83g of phthalic acid and 0.40g of sodium hydroxide in 100mL of deionized water, and dissolve 1.88g of aluminum nitrate and 2.97g of zinc nitrate in 100mL of deionized water. The two solutions were combined and stirred at 50°C for 12 hours. The white colloid solution after the reaction was centrifuged three times at 3500r / min, and then dried at 60°C for 24h.

[0027] To characterize the product,

[0028] The PXRD test of the product powder showed that the generated phthalic acid intercalated hydrotalcite composite had reliable phase purity, and the organic phthalic acid molecules were successfully intercalated between the hydrotalcite layers. It provides a guarantee for its application as a room temperature phosphorescent material.

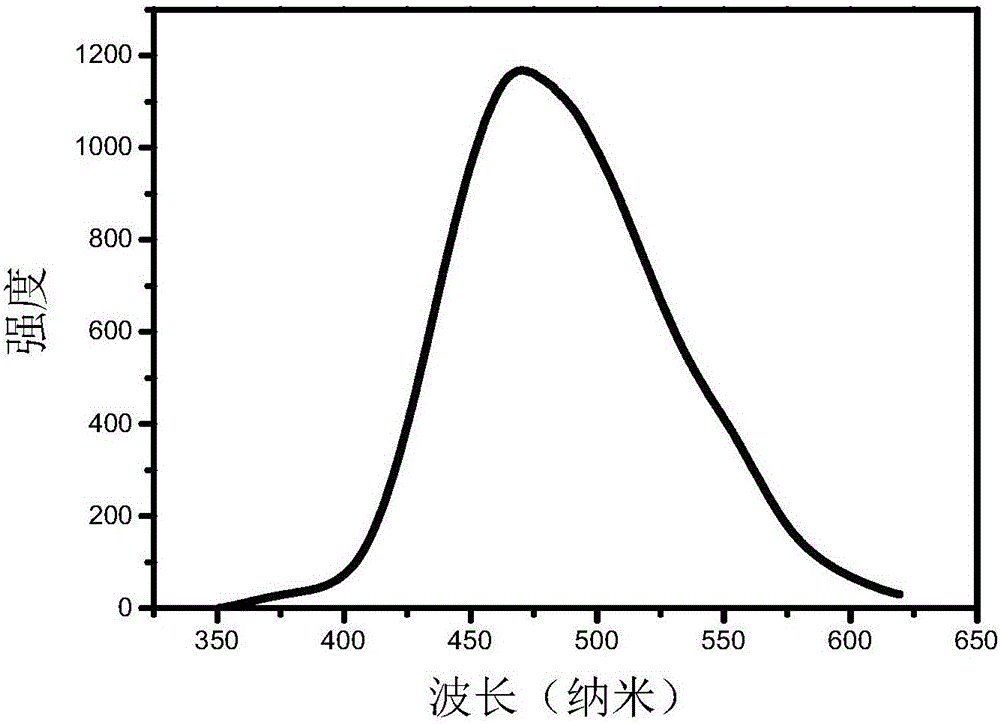

[0029] From the phosphorescence analysis, it can be seen that the phosphorescence emission peak of the phthalic acid intercalated hydrotalcite composite appears at 470 nm when excited at 320 nm, as figure 2 shown. After being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com