Water-borne graphene composite coating, and water-borne graphene composite paint and preparation method thereof

A water-based graphene and composite coating technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem that water-based coatings are difficult to form a uniform, structurally dense film structure, and it is difficult to achieve high infiltration of fillers and pigment particles. It is difficult to form high-quality anti-corrosion coatings and other problems, so as to achieve excellent anti-corrosion effect, good dispersibility and chemical stability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a method for preparing a water-based graphene composite coating. The method comprises the steps of:

[0032] Step (1): equimolar amounts of aniline oligomer derivatives and alkali are dissolved in water to obtain a mixture A. The purpose of adding alkali is to make the aniline oligomer derivatives more soluble in water. Adding an equimolar amount is to make the carboxylic acid contained in the structure of the aniline oligomer derivative, or other acid groups, completely neutralize with the alkali. The alkali is one of sodium hydroxide, triethylamine, potassium hydroxide and ammonia water.

[0033] The aniline oligomer derivative and alkali are dispersed in water to fully dissolve the aniline oligomer derivative. The aniline oligomer derivatives are used to modify the graphene. The aniline oligomer derivatives are aniline oligomers with functional groups, and the functional groups include carboxyl groups, alkyl groups...

Embodiment 1

[0050] Weigh 1.24 g of aniline trimer and dissolve it in 50 ml of THF, then add 1.04 g of succinic anhydride, react for 3 hours, and precipitate with petroleum ether to obtain aniline trimer carboxyl derivative.

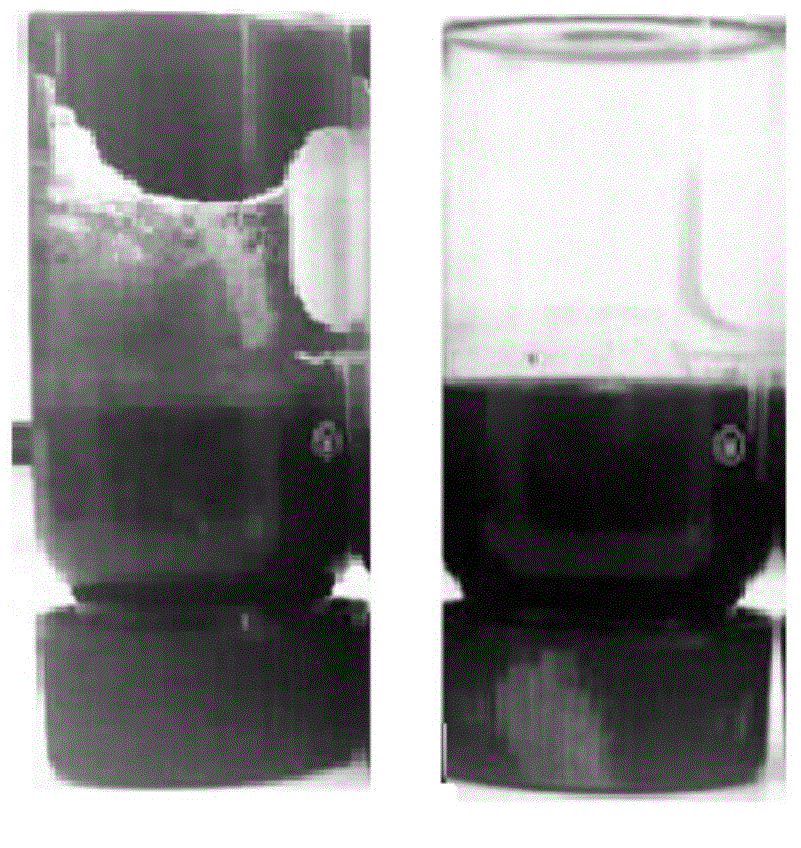

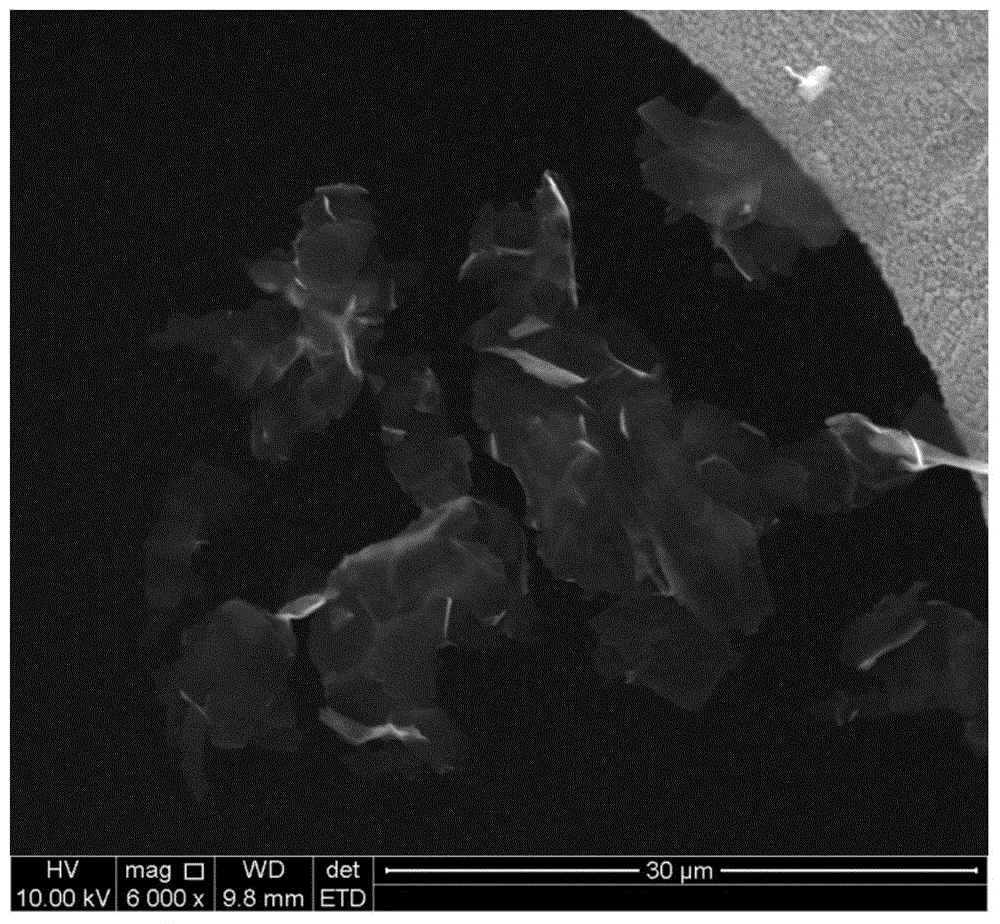

[0051] Weigh 2.0 g of aniline trimer carboxyl derivatives and 0.33 g of NaOH solid and dissolve them in 10 mL of water to obtain mixture A. 2 g of graphene (purchased from Ningbo Moxi Technology Co., Ltd.) was added to the mixture A, and ultrasonically dispersed for 1 hour to obtain a graphene dispersion. The content of graphene in water reached 0.2g / mL after modified by aniline trimer carboxyl derivative. The comparative effect of described graphene dispersion liquid and untreated graphene after water dispersion sees figure 1 . The electron transmission electron micrograph of described graphene dispersion liquid sees figure 2 . Depend on figure 1 and figure 2 It can be seen that graphene can be uniformly dispersed in water after being modified by aniline tri...

Embodiment 2

[0060] Weigh 1.5 g of the aniline trimer carboxyl derivative and 0.33 g of NaOH solid dissolved in 10 mL of water to obtain mixture A. Add 1.5 g of graphene to the mixture A, and ultrasonically disperse for 1 hour to obtain a graphene dispersion. The content of graphene in water reached 0.15g / mL after modified by aniline trimer carboxyl derivative.

[0061] The graphene dispersion was added to 92g of water-based polyurethane resin (purchased from Northwest Yongxin Group Co., Ltd.), and mixed uniformly to obtain mixture B. Add 1.67g of leveling agent, 1g of defoamer, and 2g of anti-sedimentation agent in sequence to the mixture B, and stir evenly to obtain a water-based graphene composite coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com