Method for preparing nitrogen self-doped porous graphene using porous soybean shell

A porous graphene, self-doping technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high cost of graphene acquisition, harm to human health, difficult industrial production, etc., to achieve large-scale The effect of production, saving raw material costs, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

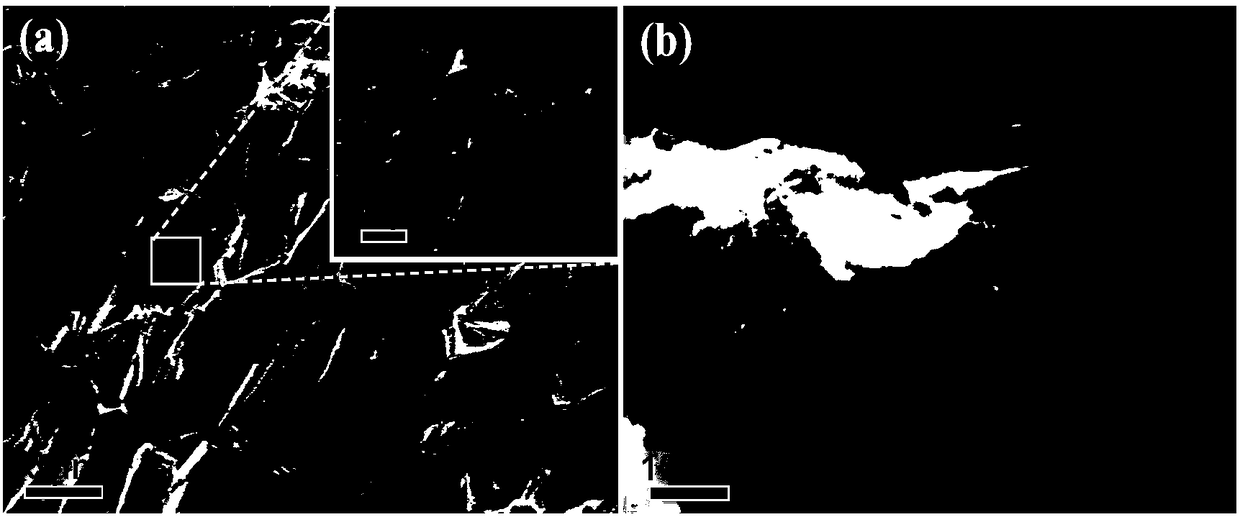

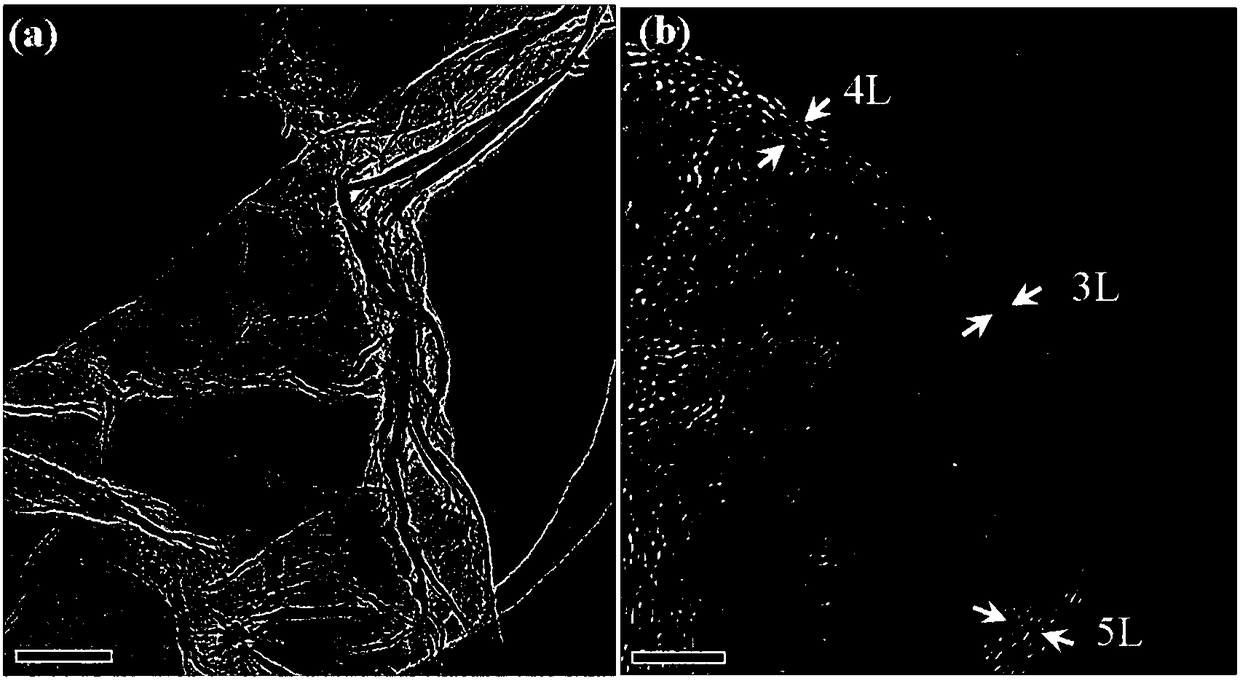

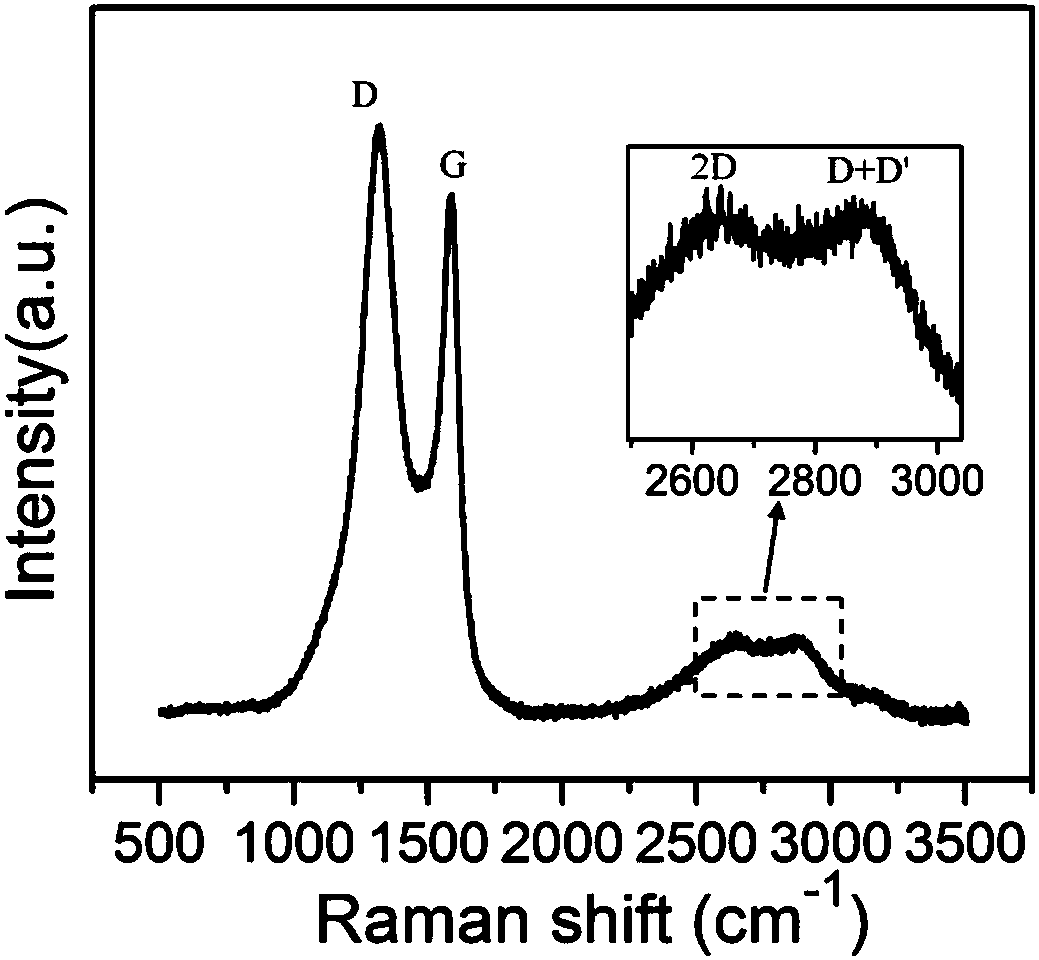

[0039] 1) Wash fresh soybean shells with water, place them in a common drying oven, and dry them at 100° C. to obtain curly dried soybean shell samples;

[0040] 2) Put the prepared soybean shell sample in step 1) in a multifunctional pulverizer, and pulverize it for 3 minutes to obtain the powder of soybean shell material;

[0041] 3) Weigh 5g of soybean shell powder and 15g of KOH solid in step 2) into a 250ml beaker, add 100g of water, stir in a constant temperature water bath at 80°C for 4h, take it out and dry it in a normal drying oven at 100°C for 24h;

[0042] 4) Place the consolidated block obtained in step 3) in a tube furnace, and raise the temperature to 800°C under an Ar gas protective atmosphere, with a heating rate of 5°C·min -1 , keep warm for 1h;

[0043] 5) After the product obtained in step 4) was manually ground, it was placed in 200ml 0.3M H 2 SO 4 Pickle in a constant temperature water bath at 80°C for 6 hours in the solution, filter with suction, and ...

Embodiment 2

[0055] 1) Wash fresh broad bean shells with water, place them in a common drying oven, and dry them at 80°C to obtain curly dried broad bean shell samples;

[0056] 2) Place the broad bean shell sample prepared in step 1) in a multifunctional pulverizer, and pulverize it for 4 minutes to obtain the powder of the bean shell material;

[0057] 3) Weigh 5g of the broad bean shell powder and 10g of KOH solid in step 2) and place it in a 250ml beaker, add 150g of water, stir in a constant temperature water bath at 90°C for 6h, take it out and dry it in an ordinary drying oven at 120°C for 48h;

[0058] 4) the consolidated block obtained in step 3) is placed in a tube furnace, and the 2 The temperature was raised to 550°C under a gas-protected atmosphere, and the heating rate was 6°C·min -1 , keep warm for 1.5h;

[0059] 5) After the product obtained in step 4) was manually ground, it was placed in 250ml 0.4M H 2 SO 4 Pickle in a constant temperature water bath at 80°C for 8 hou...

Embodiment 3

[0063] 1) Wash fresh mung bean shells with water, place them in a common drying oven, and dry them at 80° C. to obtain curly dried mung bean shell samples;

[0064] 2) Place the prepared mung bean shell sample in step 1) in a multifunctional pulverizer, and pulverize it for 3 minutes to obtain the powder of the mung bean shell material;

[0065] 3) Weigh 5g of the mung bean shell powder and 15g of KOH solid in step 2) and place it in a 250ml beaker, add 150g of water, stir in a constant temperature water bath at 70°C for 3h, take it out and dry it in an ordinary drying oven at 90°C for 20h;

[0066] 4) Put the consolidated block obtained in step 3) in a tube furnace, and raise the temperature to 600°C under the protective atmosphere of Ar gas, and the heating rate is 5°C·min -1 , keep warm for 2h;

[0067] 5) After the product obtained in step 4) was manually ground, it was placed in 250ml 0.5M H 2 SO 4 Pickling in a constant temperature water bath at 70°C for 7 hours in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com