High-carbon high-chrome high-vanadium wearable surfacing self-shielded flux-cored wire

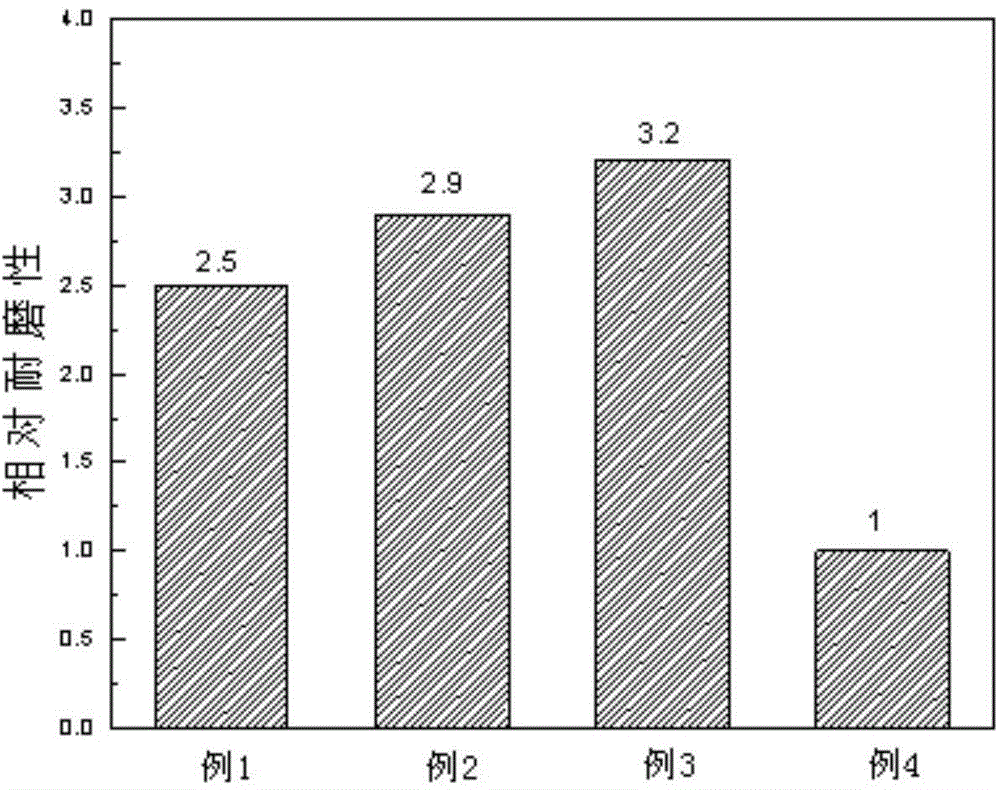

A technology of flux-cored welding wire, high carbon and high chromium, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high brittleness, easy to drop blocks, and shortened service life, so as to improve hardness and wear resistance properties, excellent anti-block performance, and the effect of uniform crack morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

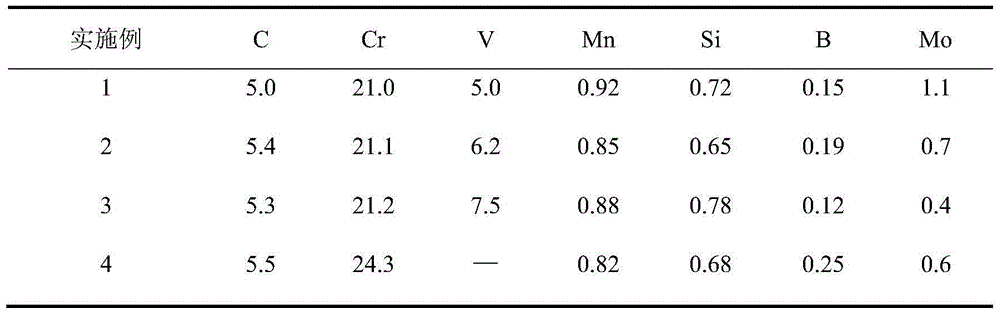

Embodiment 1

[0020] Low carbon steel strip H08A is used, its thickness is 0.3mm, and its width is 16mm.

[0021] The drug core components are: 100g high carbon ferrochrome, 450g chromium carbide, 200g ferrovanadium, 35g ferromolybdenum, 20g electrolytic manganese, 20g ferrosilicon, 18g ferroboron, 20g graphite, 13g aluminum magnesium, 10g barium fluoride, barium carbonate 13g, marble 10g, fluorite 13g, iron powder 78g, a total of 1000g powder, the weight ratio is 50%.

[0022] The above-mentioned low-carbon steel strip and flux core were made into a flux-cored welding wire with a diameter of 3.2 mm.

Embodiment 2

[0024] Low carbon steel strip H08A is used, its thickness is 0.3mm, and its width is 16mm.

[0025] The drug core components are: 63g of high-carbon ferrochrome, 500g of chromium carbide, 250g of ferro-vanadium, 25g of ferro-molybdenum, 20g of electrolytic manganese, 20g of ferrosilicon, 22g of ferro-boron, 20g of graphite, 14g of aluminum magnesium, 14g of zircon sand, fluoride Barium 16g, barium carbonate 20g, marble 16g, totally 1000g powder, the counterweight ratio is 50%.

[0026] The above-mentioned low-carbon steel strip and flux core were made into a flux-cored welding wire with a diameter of 3.2 mm.

Embodiment 3

[0028] Low carbon steel strip H08A is used, its thickness is 0.3mm, and its width is 16mm.

[0029] The drug core components are: 50g of high-carbon ferrochrome, 500g of chromium carbide, 300g of ferrovanadium, 15g of ferromolybdenum, 20g of electrolytic manganese, 20g of ferrosilicon, 16g of ferroboron, 20g of graphite, 10g of aluminum magnesium, 8g of barium fluoride, and 13g of marble , sodium fluorosilicate 11g, iron powder 17g, a total of 1000g powder, the weight ratio is 50%.

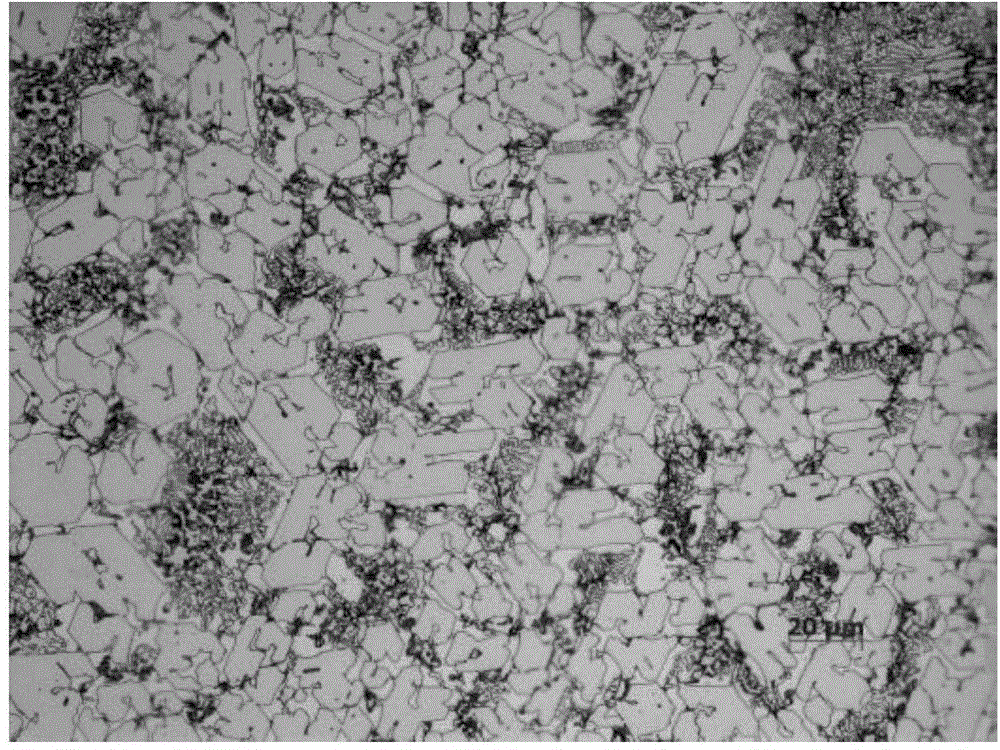

[0030] The above-mentioned low-carbon steel strip and flux core are made into a flux-cored wire with a diameter of 3.2 mm, and the flux-cored wire is made into a surfacing alloy. The metallographic diagram of the surfacing alloy is as follows figure 2 As shown, it can be seen from the figure that the surface structure of the surfacing layer is uniform, and there are no defects such as pores, slag inclusions, and undercuts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com