Low-temperature vapor deposition method for carbon-based super-lubricating thin film with onion structure

A vapor deposition and super-lubricating technology, applied in metal material coating process, vacuum evaporation plating, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method of low-temperature vapor deposition of onion structure carbon-based super-lubricating film mainly includes the following steps:

[0020] 1) Place the silicon wafers in acetone and absolute ethanol, respectively, and clean them with ultrasonic for 10 minutes, then rinse with deionized water, blow dry with nitrogen, and send them to the vacuum chamber;

[0021] 2) When the vacuum is reduced to less than 4.0×10-3 Pa, pass the working gas (Ar with a purity of 99.999%) to a pressure of 2 to 3 Pa, and apply a negative bias of -1000 to -1200V to the substrate for plasma Glow cleaning for 10min;

[0022] 3) Maintain bias voltage -1000V, frequency 3.5KHz, duty cycle 15%. During the deposition process, the Ar gas flow rate is maintained at 80 sccm, the CH4 flow rate is 40 sccm, the air pressure is maintained at 0.45 to 0.5 Pa, and the target power is 800 to 900 W. The deposition time is 1 h. The thickness of the deposited film is about 1 μm.

Embodiment 2

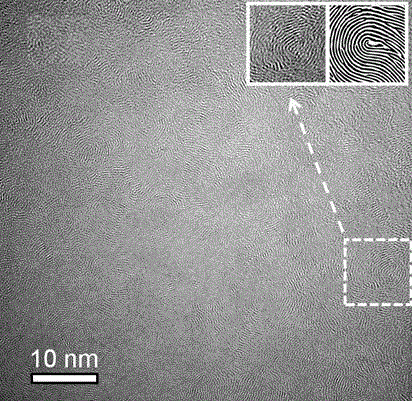

[0024] 1. The JEM3010 high-resolution transmission electron microscope (HRTEM) was used to characterize the microscopic morphology of the film. As shown in Figure 1, the film is composed of onion carbon embedded in an amorphous network.

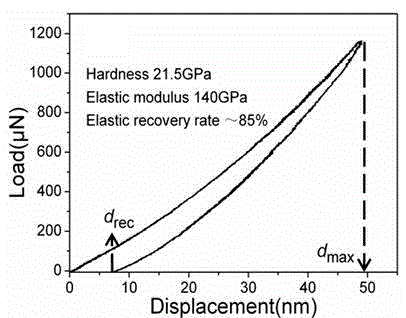

[0025] 2. Use Nano-indenter II nano indenter to measure the hardness and elastic recovery of the film, and the indentation depth is 100nm, such as figure 2 As shown, the onion structure carbon film has a hardness of 21.5 GPa, an elastic modulus of 140 GPa, and an elastic recovery of 85%, indicating that the film has good toughness and strength.

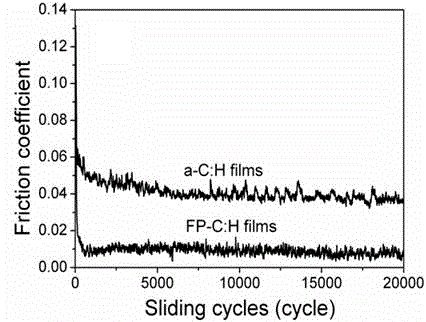

[0026] 3. Using the UMT friction testing machine, the friction curve of the traditional a-C:H film is compared with the traditional a-C:H film under a load of 20N and a frequency of 10Hz ( image 3 ), the friction coefficient of the onion carbon film is 1 / 6 of the traditional a-C:H film, about 0.008, showing super lubricating performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com