Micro-powder aluminum hydroxide preparation method and device and micro-powder aluminum hydroxide

A technology of aluminum hydroxide and micropowder, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, purification of aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, etc., can solve the problem of oil absorption High rate, high sodium oxide content, poor processing performance and other problems, to achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] See attached figure 1 , the preparation method of micropowder aluminum hydroxide provided by Example 1 of the present invention comprises the following steps:

[0053]Step S1: adding aluminum hydroxide seeds obtained through carbonation and decomposition of the sodium aluminate solution to the sodium aluminate solution, performing temperature-variable seed decomposition to obtain a decomposed slurry;

[0054] Step S2: removing iron in the decomposed slurry to obtain a first intermediate product;

[0055] Step S3: After washing the first intermediate product, depolymerize it to obtain the second intermediate product;

[0056] Step S4: removing the moisture in the second intermediate product to obtain the third intermediate product;

[0057] Step S5: Dispersing and classifying the third intermediate product to produce micronized aluminum hydroxide.

[0058] The mass percentages of each component of the micropowder aluminum hydroxide prepared by the preparation method o...

Embodiment 2

[0067] See attached figure 2 , The micropowdered aluminum hydroxide preparation equipment provided by Example 2 of the present invention includes a decomposition tank, an iron removal device, a first washing device, a depolymerization device, a water removal device, a dispersion and a classification device, and the decomposition tank is used to accommodate sodium aluminate The solution and the aluminum hydroxide seed obtained through the carbonation and decomposition of the sodium aluminate solution are used to decompose the sodium aluminate solution at variable temperatures to obtain the decomposed slurry; the iron removal device is used to decompose the iron in the slurry to obtain the first Intermediate product; the first washing device is used for washing the first intermediate product; the depolymerization device is used for depolymerizing the washed first intermediate product to obtain the second intermediate product; the water removal device is used for removing the moi...

Embodiment 3

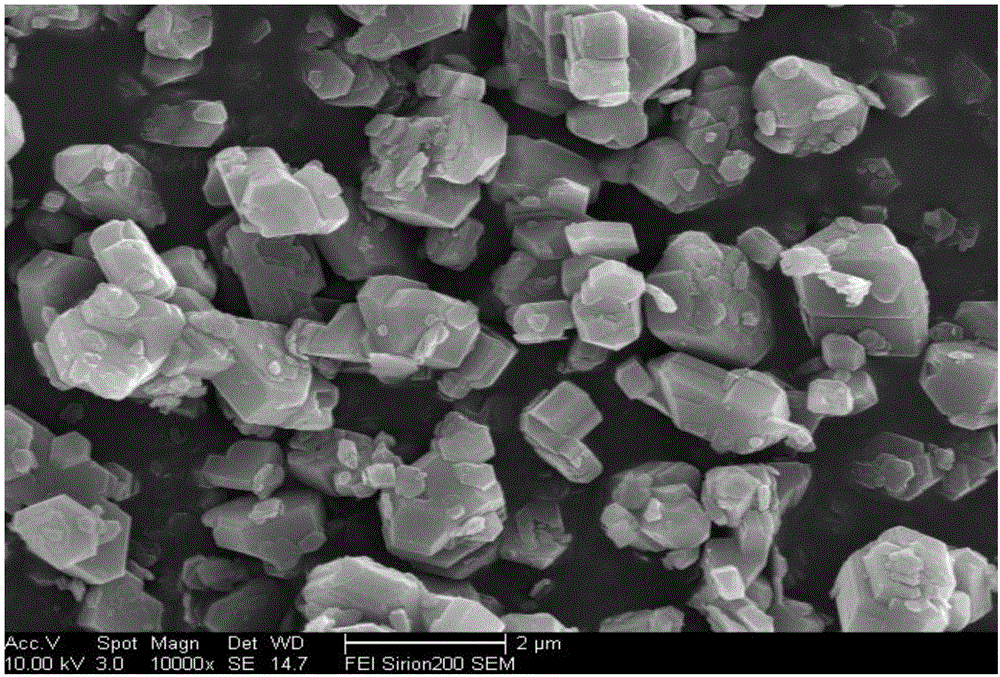

[0078] See attached image 3 , the micropowder aluminum hydroxide provided in Example 3 of the present invention is prepared using the micropowder aluminum hydroxide preparation equipment provided in Example 2 of the present invention, and is prepared by the preparation method of micropowder aluminum hydroxide provided in Example 1 of the present invention, and the parameters of micropowder aluminum hydroxide As follows: the mass percentages of each component are: Fe 2 o 3 : 0.008%, Na 2 O: 0.086%, Na 2 o (s) : 0.009%, SiO 2 : 0.01%; whiteness: 98.2%; D50: 1.26μm; water attached: 0.209%; oil absorption: 33; D90: 1.1.97μm.

[0079] The preparation method of the micropowder aluminum hydride used in Examples 4-20 of the present invention is the same as the preparation method of the micropowder aluminum hydride used in Example 1 or 2 of the present invention, but the operating parameters and result parameters are different; The preparation equipment of the micropowder alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com