Method for predicting hydrogen sulfide output in drainage pipeline

A technology for drainage pipelines and prediction methods, which is applied in chemical process analysis/design, special data processing applications, instruments, etc., can solve the problem of inability to simulate biological dynamic changes in sewers, inconvenient prediction of hydrogen sulfide production and discharge, and inability to accurately predict hydrogen sulfide emissions. quantity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

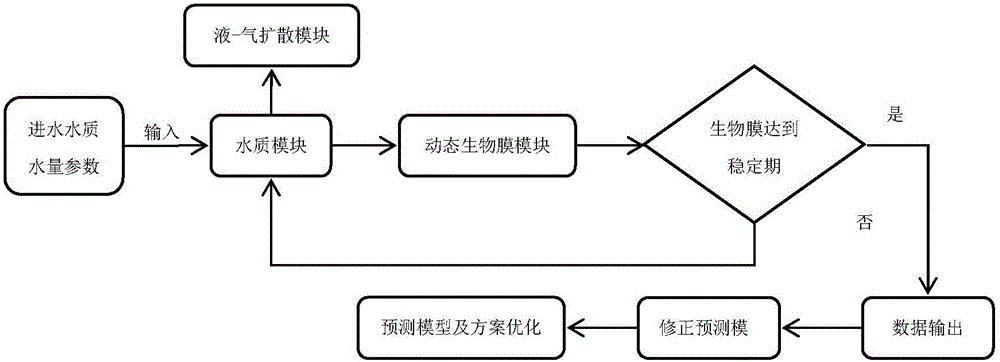

[0117] refer to figure 1 Schematic flow chart of , a method for predicting the amount of hydrogen sulfide produced in drainage pipes, including:

[0118] S1. Analyze the intensive sampling characteristics of the sewage in the drainage pipe, measure the real-time parameters of the influent water quality and water quantity and the effluent water quality and quantity parameters, and obtain the pipeline parameters of the drainage pipe at the same time; specifically: collect an influent water sample and water quantity every 2 hours The effluent water samples were intensively sampled continuously for 48 hours. The influent water samples were used to calibrate the prediction model; the effluent water samples were used to verify the simulation degree of the model. h 2 S gas concentration. When sampling, the sampling frequency and time can be adjusted arbitrarily as required. Influent water quality and quantity parameters and effluent water quality and quantity parameters refer to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com