Method for detecting purity of 3-methylamino-1,2-propandiol by gas chromatography

A gas chromatography, methylamine-based technology, which is applied in the field of separation of various impurity components in 3-methylamino-1,2-propanediol, can solve the problem that the accuracy of data is difficult to guarantee, the post-processing steps are complicated, and the amount of n-hexane Large and other problems, to achieve the effect of simple operation, saving analysis time, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

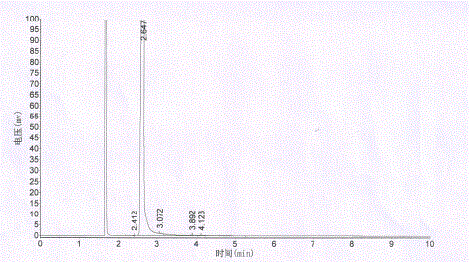

[0061] Embodiment 1 solvent screening test

[0062] Due to the high viscosity of 3-methylamino-1,2-propanediol, the impurities in 3-methylamino-1,2-propanediol cannot be separated by direct injection, so solvent dilution was considered to reduce the viscosity of the injection.

[0063] The applicant selected ethanol, acetone, trichloroethane, n-hexane, etc. to dissolve 3-methylamino-1,2-propanediol, and carried out analysis experiments under the same detection conditions.

[0064] When acetone is used, acetone reacts rapidly with 3-methylamino-1,2-propanediol, and the sample gradually changes from colorless to light yellow in a short period of time, and the peaks of each component in the detection spectrum overlap and are difficult to separate;

[0065] Using ethanol and trichloroethane, although the separation effect of the main component 3-methylamino-1,2-propanediol is better, either low boilers (refers to boiling points lower than 3-methylamino-1,2-propanediol) Components...

Embodiment 2

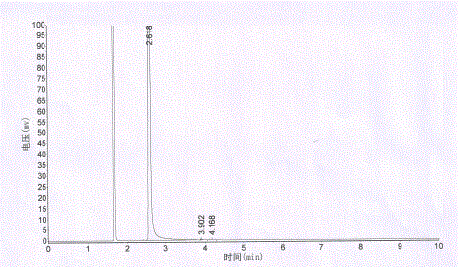

[0068] Embodiment 2 A method for detecting the purity of 3-methylamino-1,2-propanediol by gas chromatography

[0069] Include the following steps:

[0070] 1. Sample preparation

[0071] Dissolve about 0.1 mL of 3-methylamino-1,2-propanediol in 2 mL of chromatographically pure methanol, fully dissolve and set aside.

[0072] 2. Setting of chromatographic conditions

[0073] (1) Chromatograph (FL9790 produced in Wenling, Zhejiang);

[0074] (2) Detector (FID), hydrogen flame ionization detector;

[0075] (3) Agilent gas chromatography column, DB-1701 (30m×0.32mm×0.5um) quartz capillary column;

[0076] (4) Column temperature, 240°C; injection volume 0.2 μL, split injection, split ratio 20:1; carrier gas nitrogen, flow rate 40mL / min; air flow rate 450mL / min; hydrogen 45mL / min;

[0077] (5) Temperature of vaporization chamber, 280°C;

[0078] (6) Detector temperature, 280°C.

[0079] 3. Detection operation

[0080] Turn on the power of the chromatograph and turn it on. Be...

Embodiment 3

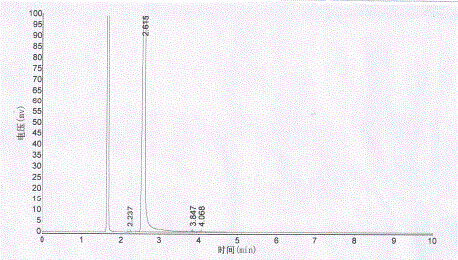

[0091] Embodiment 3 A method for detecting the purity of 3-methylamino-1,2-propanediol by gas chromatography

[0092] Control: On the basis of the method in Example 2, only the column temperature was changed, the temperature of the vaporization chamber was not changed, and the column temperature was only raised to 260°C. The experimental result: the low boilers before the main peak came out, but the peak was not obvious , the separation effect is very poor; there should be three peaks after the main peak, but there are only two peaks.

[0093] The reason for the analysis is that the temperature of the vaporization chamber is low. According to the general law of gas chromatographic analysis, the temperature of the injection port should be higher than the boiling point of the analyte to ensure that all analytes can be completely vaporized after being injected through the injection port. The inlet temperature is a prerequisite for GC analysis. If the temperature is too high, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com