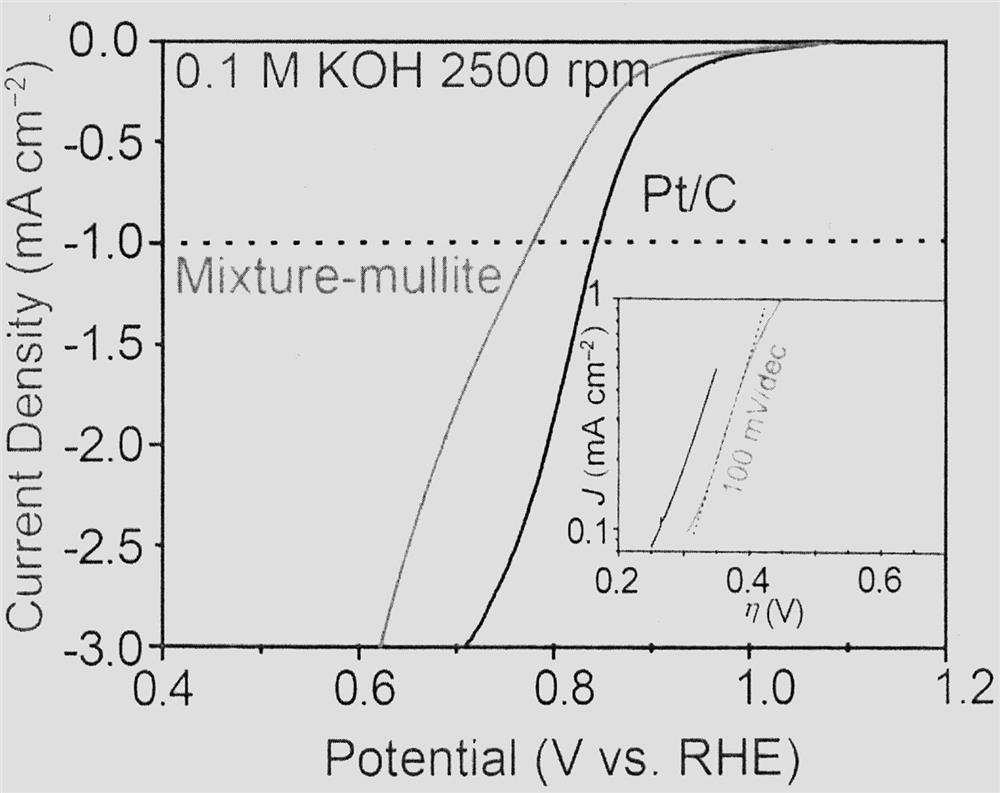

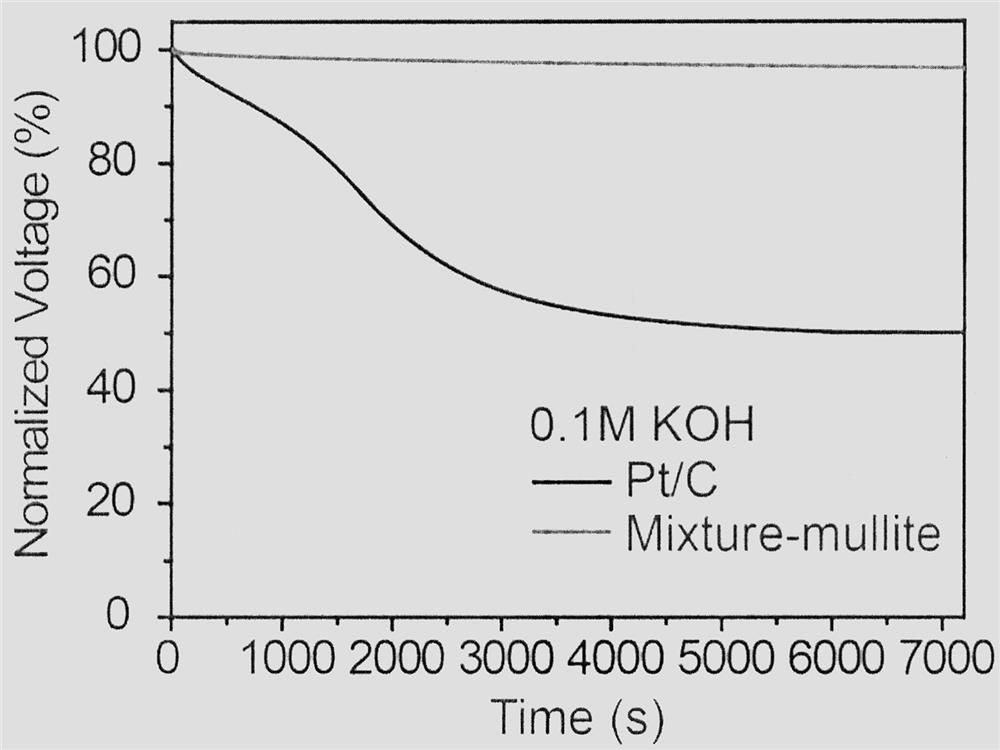

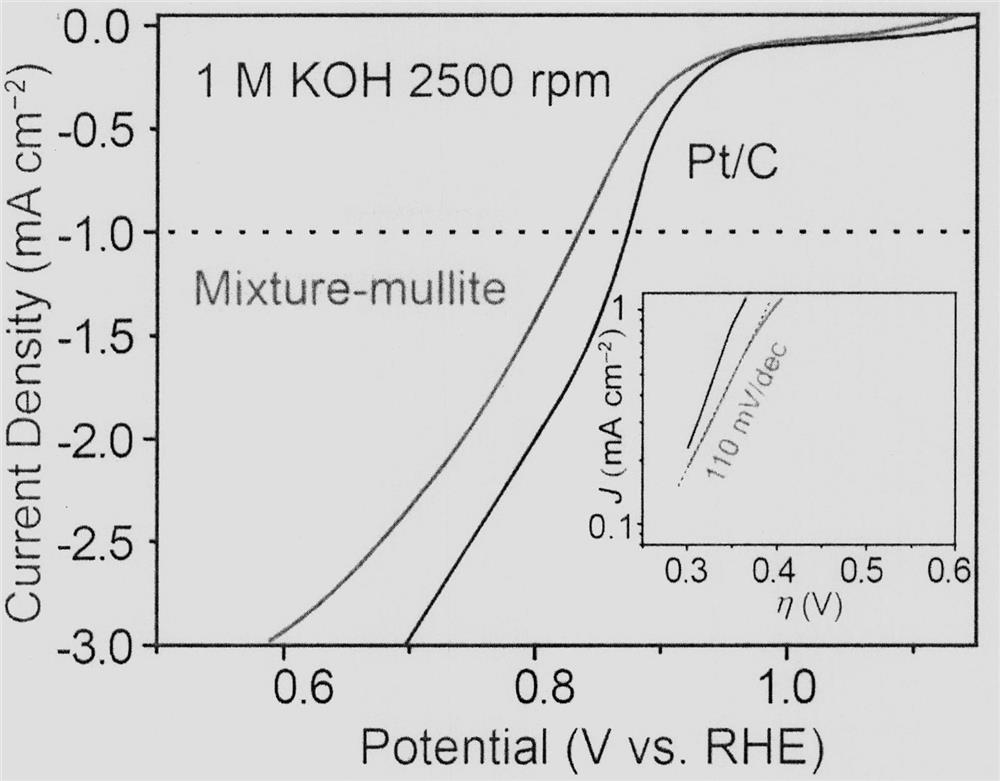

A mixed-phase mullite-type electrocatalyst for air battery or fuel cell cathode

A fuel cell cathode and air battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as high overpotential, low platinum element reserves, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. A magnesium-air three-electrode battery, comprising the above-mentioned catalytic layer as positive pole, magnesium foil as negative pole, saturated Ag / AgCl solution as reference electrode, and neutral 1M NaCl aqueous solution as electrolyte. The battery container adopts H-shaped glass battery. The nickel foam coated on the catalytic layer is the current collector layer. In order to match the framework of the H battery, the nickel foam was cut into a size of 1 cm × 5 cm, and one end was coated with a catalyst substance covering an area of 1 cm × 2 cm, and the area was soaked in the electrolyte. During work, it is necessary to continuously blow air into the positive part of the catalytic layer to ensure the supply of oxygen.

[0045] Experiments have shown that the initial magnesium-air battery voltage can reach 1.65V, and when the current is as high as 1.0mA / cm 2 , the voltage can also reach 1.2V, and it can be maintained for 150 minutes. After that, the voltage...

Embodiment 2

[0047] 2, a kind of magnesium-air two-electrode button battery, magnesium foil, diaphragm, the catalytic layer that is coated on the foamed nickel are piled up successively, and are encapsulated in the button battery (model: CR2032), obtain magnesium-air battery unit, above-mentioned The catalytic layer is used as the positive electrode, the magnesium foil is used as the negative electrode, the neutral NaCl solution is used as the electrolyte, and the hydrophilic Celgard (Celgard) 3501 is used as the diaphragm between the two electrodes. Multiple units connected in series constitute a magnesium-air battery pack.

[0048] Connect three button battery units in series on the circuit board, and connect the positive and negative terminals to LED lights, then add 0.5 ml of 1M NaCl solution to the three batteries, wait for the electrolyte to soak into the button battery for a minute or two , 1.8V LED lights can emit light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com