Alkali metal ion capacitor taking lithium orthovanadate as negative electrode active material

A technology of negative electrode active material and positive electrode active material, applied in the field of electrochemistry, can solve the problems of low energy density of alkali metal ion capacitors, and achieve the effects of excellent cycle performance, good rate performance and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

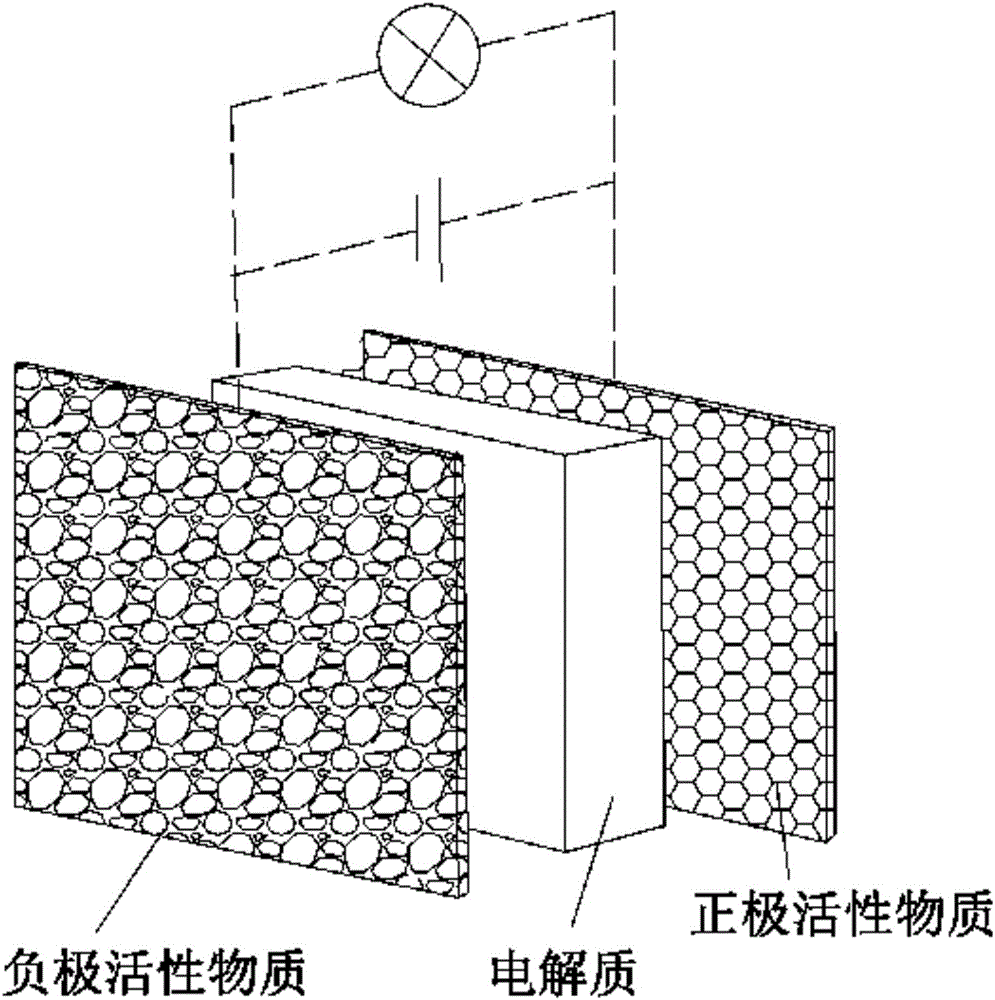

Method used

Image

Examples

Embodiment 1

[0042] Mix vanadium pentoxide and lithium carbonate according to the V:Li molar ratio of 1:3, grind for 10 minutes, and calcinate the obtained powder at 600°C for 5 hours, then at 900°C for 3 hours, and cool in the furnace Lithium orthovanadate (Li 3 VO 4 )sample. Accurately weigh lithium orthovanadate, acetylene black and polyvinylidene fluoride (PVDF) according to the mass fraction of 80%: 10%: 10%, use 1-methyl-2-pyrrolidone as a solvent, and uniformly mix to form a slurry, Spread evenly on copper foil. The coated electrode sheet was vacuum-dried at 120°C for more than 12 hours, and an electrode with a diameter of 19 mm was punched out with a punching machine. With this electrode as the negative pole, the activated carbon electrode prepared in Comparative Example 1 as the positive pole, the porous polypropylene with a porosity of 40% as the diaphragm, 1MLiPF 6 A mixed solution of ethylene carbonate (EC) / dimethyl carbonate (DMC) / diethyl carbonate (DEC) (mass ratio 1:1:1)...

Embodiment 2

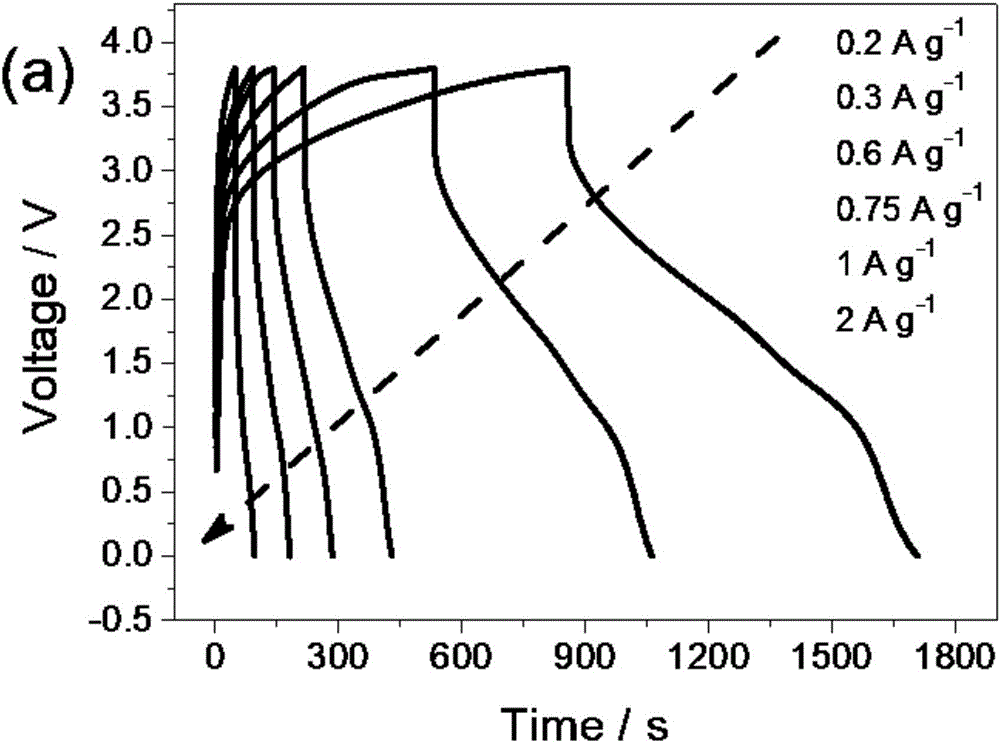

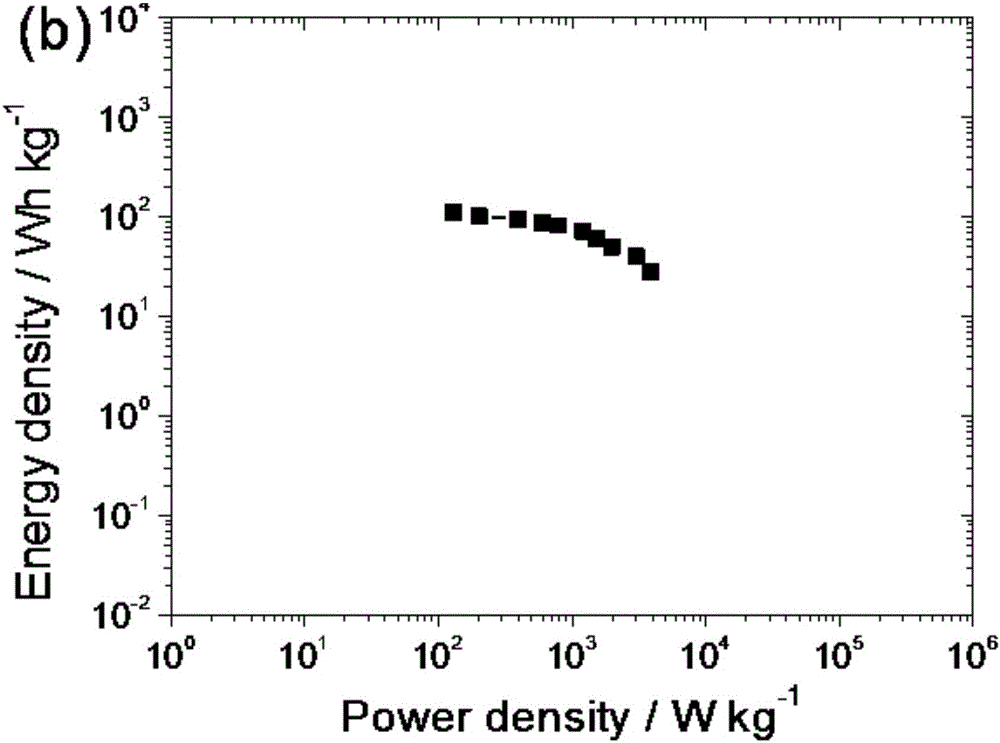

[0044] Lithium orthovanadate (Li 3 VO 4 ) was prepared the same as in Example 1, and then passed through high-speed ball milling with carbon nanofibers (CNF) to obtain Li 3 VO 4 -CNF compound, according to the method of Example 1 to prepare the negative electrode. Using graphene with an average thickness of 10 layers of graphite sheets as the positive electrode active material, a positive electrode was prepared according to the method of Comparative Example 1. Then change the diaphragm into P(VDF-HFP) with a porosity of 45%, and other conditions are the same as in Example 1 to form an asymmetric lithium ion capacitor, and carry out corresponding electrochemical performance (the voltage range is 0-3.8 V) and safety performance test (overcharged to 4.5V), the relevant test data are collected in Table 1. figure 2 , image 3 They are the charge-discharge curves and the relationship between energy density and power density at different current densities.

Embodiment 3

[0046] According to our disclosed method (journal NanoLetters, the 4715-4720 page of volume 13 in 2013), adopt hydrothermal method to obtain lithium orthovanadate (Li 3 VO 4 ) and graphene (G), and then prepared as a negative electrode according to the method of Example 2. Using graphene with an average thickness of 10 layers of graphite sheets as the positive electrode active material, a positive electrode was prepared according to the method of Comparative Example 1. Then, change the electrolyte to 1MNaPF 6 Outside the mixed solution of ethylene carbonate (EC) / dimethyl carbonate (DMC) / diethyl carbonate (DEC) (mass ratio 1:1:1), the diaphragm is the same as in Example 2 to form an asymmetric sodium ion capacitor , carry out the corresponding electrochemical performance (voltage range of 0-3.8V) and safety performance test (overcharge to 4.5V), and collect the relevant test data in Table 1.

[0047] The highest energy density and the highest power density situation (accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com