A prefabricated concrete sandwich insulation exterior wall panel connected by W-shaped steel core and glass fiber bars

A technology of prefabricated concrete and thermal insulation exterior walls, which is applied in thermal insulation, building components, construction, etc., and can solve the problems that hinder the large-scale application of prefabricated concrete sandwich insulation exterior wall panels, affect the wall insulation effect, and have large thermal conductivity of materials, etc. , to achieve the effect of enhancing the overall working performance, improving the connection and anchoring effect, and having a small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

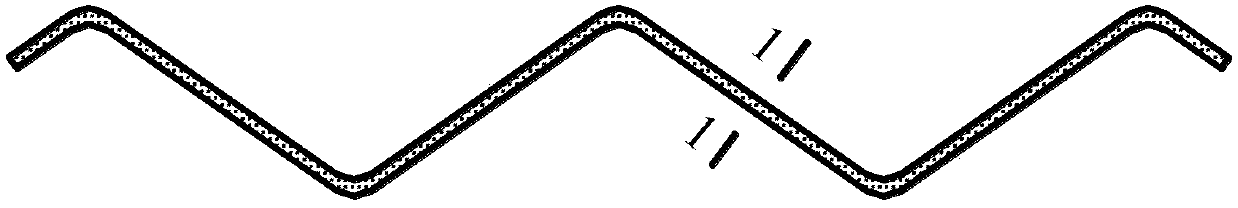

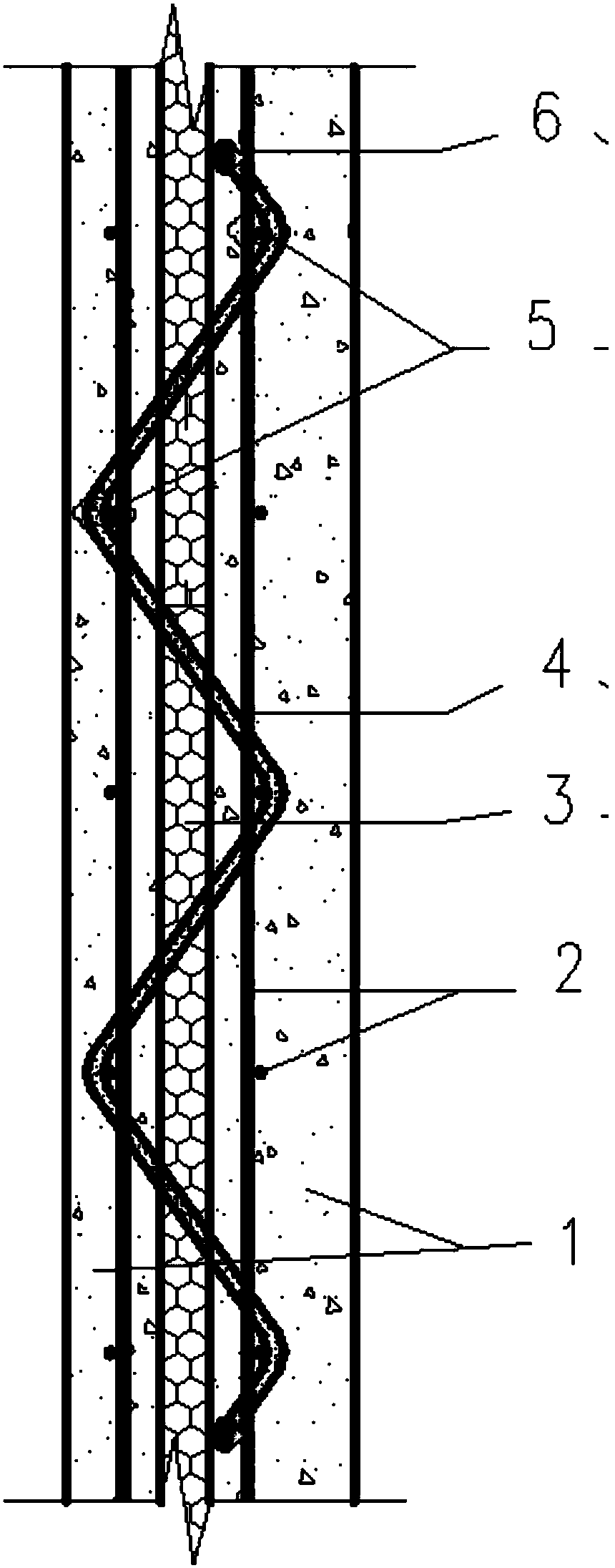

[0018] Such as Figure 1-4 As shown, a prefabricated concrete sandwich thermal insulation exterior wall panel connected by W-shaped steel core glass fiber bars has a three-layer structure, which is the inner leaf concrete wall panel, the insulation layer 3, and the outer leaf concrete wall panel. The rib connector 4 connects the three-layer structure into a whole;

[0019] The inner and outer leaf concrete wall panels 1 are poured with ordinary concrete or light aggregate concrete, and the inner and outer leaf concrete wall panels 1 are equipped with steel mesh sheets 2, and the thermal insulation layer 3 is a non-flammable insulation board. The similarities and differences in the thickness of concrete wall panels 1 are divided into two types: center and offset;

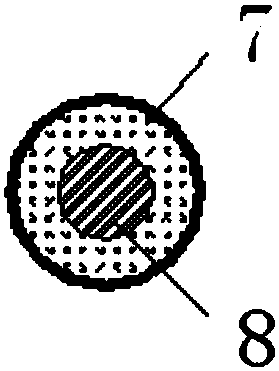

[0020] The steel bar core glass fiber bar connector 4 is to wrap the continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com