A kind of PE-PS alloy with high wear resistance and electrical conductivity and preparation method thereof

A PE-PS, electrical conductivity technology, applied in the field of PE-PS alloy and its preparation, can solve the problems of poor compatibility and high catalyst cost, and achieve the effects of improving compatibility, good wear resistance and improving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

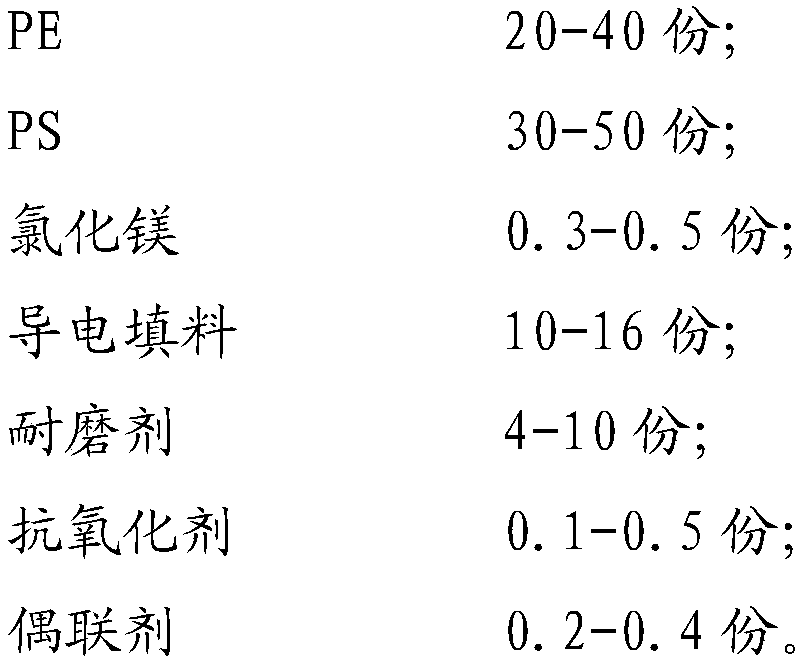

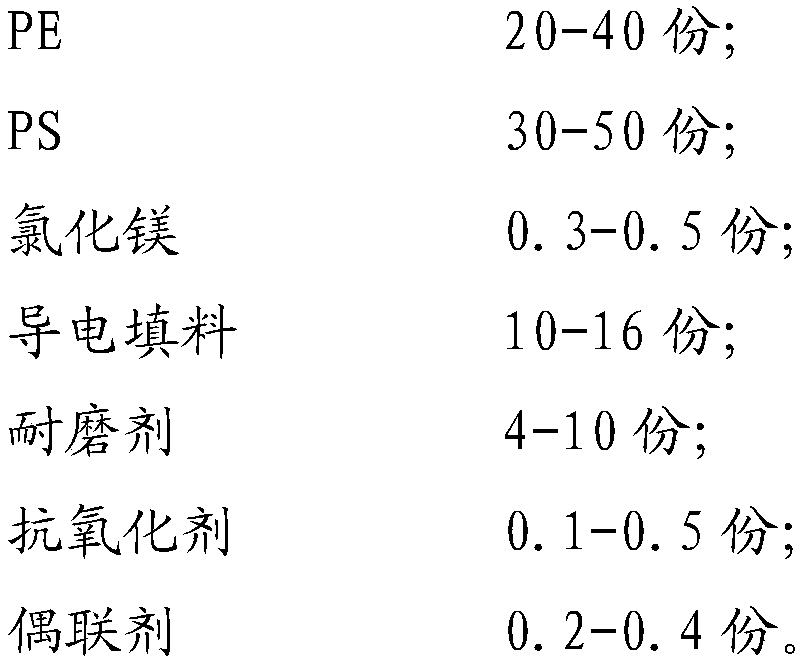

Method used

Image

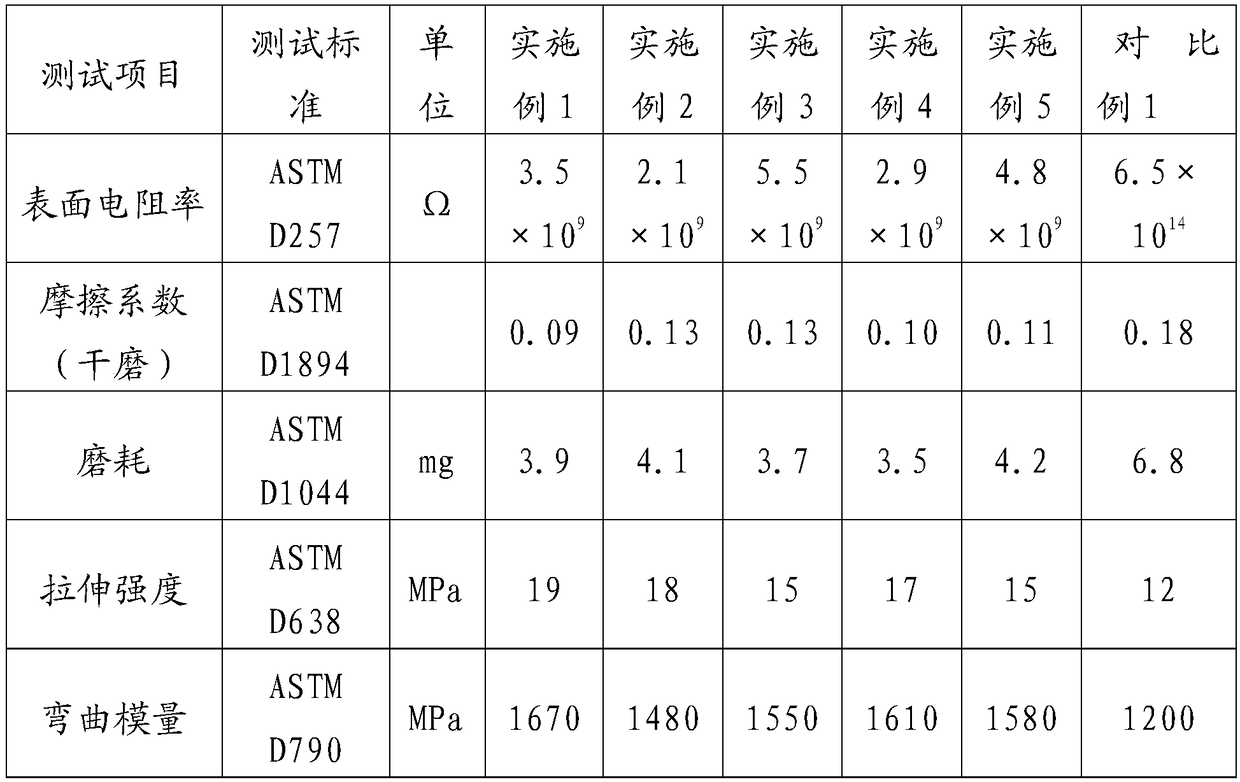

Examples

Embodiment 1

[0037] Weigh 20 parts of PE, 30 parts of PS, 2 parts of boron carbide, 2 parts of tetrafluoroethylene, 10 parts of graphene, 0.3 parts of MgCl 2 , 0.05 parts of Irganox1010, 0.05 parts of Irganox168 and 0.2 parts of AC-201.

[0038] The above materials were stirred together by a high-speed mixer for 10 minutes to form a mixed material. Among them, the temperature of the high-speed mixer is 70° C., and the rotation speed is 120 r / min.

[0039] The mixed material is put into the hopper of the twin-screw extruder, and the obtained product is melted, extruded and granulated, water-cooled, diced and dried.

[0040] The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are respectively: the temperature of the first zone is 150°C, the temperature of the second zone is 170°C, the temperature of the third zone is 170°C, the temperature of the fourth zone is 170°C, the temperature of the fifth zone is 170°C, and the temperature of the sixt...

Embodiment 2

[0042] Weigh 40 parts of PE, 50 parts of PS, 5 parts of boron carbide, 5 parts of tetrafluoroethylene, 16 parts of graphene, 0.5 parts of MgCl 2 , 0.25 parts of Irganox1010, 0.25 parts of Irganox168 and 0.4 parts of AC-201.

[0043] The materials were stirred together by a high-speed mixer for 12 minutes to form a mixed material. Among them, the temperature of the high-speed mixer is 120° C., and the rotation speed is 240 r / min.

[0044] The mixed material is put into the hopper of the twin-screw extruder, and the obtained product is melted, extruded and granulated, water-cooled, diced and dried.

[0045] The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are respectively: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 200°C, the temperature of the fifth zone is 200°C, and the temperature of the sixth zon...

Embodiment 3

[0047] Weigh 30 parts of PE, 40 parts of PS, 3.5 parts of boron carbide, 3.5 parts of tetrafluoroethylene, 13 parts of graphene, 0.3 parts of MgCl 2 , 0.15 parts of Irganox1010, 0.15 parts of Irganox168 and 0.3 parts of AC-201.

[0048] The materials were stirred together by a high-speed mixer for 11 minutes to form a mixed material. Wherein, the temperature of the high-speed mixer is 95° C., and the rotation speed is 180 r / min.

[0049] The mixed material is put into the hopper of the twin-screw extruder, and the obtained product is melted, extruded and granulated, water-cooled, diced and dried.

[0050] The twin-screw extruder consists of six zones, in which the temperature and screw speed of each zone are respectively: the temperature of the first zone is 165°C, the temperature of the second zone is 185°C, the temperature of the third zone is 185°C, the temperature of the fourth zone is 185°C, the temperature of the fifth zone is 185°C, and the temperature of the sixth zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com