Method for preparing selenium-containing degradable polymer through ring-opening polymerization and application thereof to hydrogel

A technology for degrading polymers and ring-opening polymerization, which can be used in drug combination, drug delivery, and pharmaceutical formulations. Degradation and other problems, to achieve the effect of accurate molecular structure, molecular weight and molecular weight distribution controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1 Preparation of di-selenium ethanol

[0038] Add 0.35g sodium borohydride (NaBH 4 ) And 150mL of deionized water, stir well, weigh 0.35g of selenium powder (Se) into the above solution, react at room temperature for 10 minutes, then add 0.35g of selenium powder, and heat the oil bath to 80°C for 3 hours. Under the protection of argon, 1.1074g of 2-bromoalcohol (HOCH 2 CH 2 Br) in tetrahydrofuran (THF) solution, react for 6 hours. The reaction solution was filtered, and the filtrate was extracted with dichloromethane three times, added with anhydrous magnesium sulfate and dried overnight, and separated by column chromatography to obtain diselenethanol (HOCH 2 CH 2 SeSeCH 2 CH 2 OH).

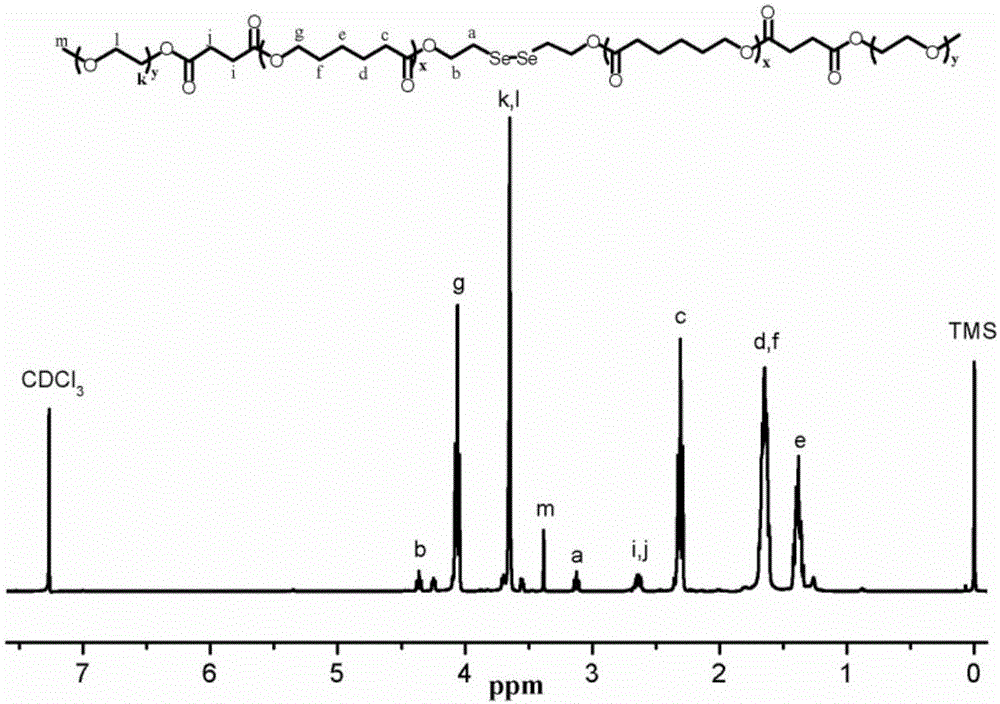

[0039] Step 2 polycaprolactone-co-SeSe-co-polycaprolactone (PCL n -SeSe-PCL n )Synthesis

[0040] Under the protection of argon, 0.75g caprolactone (CL) and 0.196g initiator diselenyl alcohol (HOCH 2 CH 2 SeSeCH 2 CH 2 OH), by controlling HOCH 2 CH 2 SeSeCH 2 CH 2 The ratio of OH to CL give...

Embodiment 2

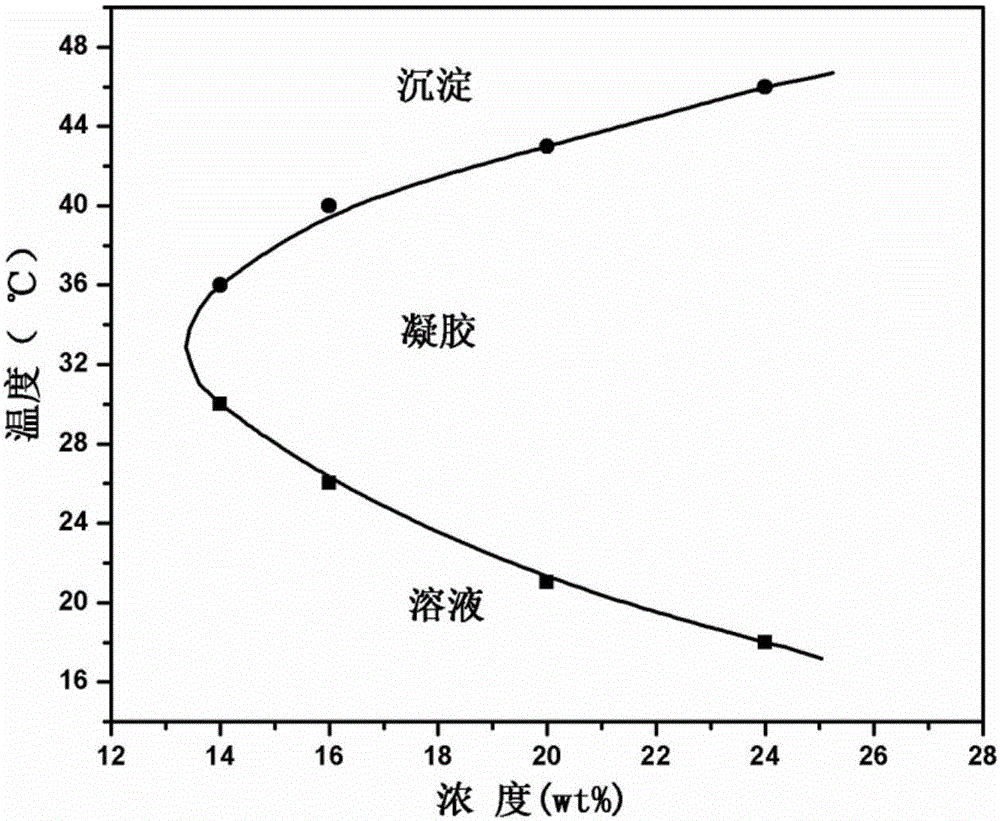

[0046] mPEG 12 PCL n -SeSe-PCL n mPEG 12 Thermal transition properties of triblock copolymers

[0047] The sol-gel transition behavior of the selenium-containing polymer aqueous solution in Example 1 was measured at different concentrations. Prepare polymer aqueous solutions of different concentrations, stabilize in a 60℃ water bath for 10 minutes, quench in an ice water bath, and stir evenly. Place it in a constant temperature water bath at 10°C, keep it for 30min, slowly increase the temperature, and observe the viscosity change between 10-50°C. The interval between two heatings is 1℃, each temperature is kept for 15 minutes, and then the test tube is turned upside down for 30 seconds to observe whether the liquid in the test tube is flowing. If the liquid does not flow in the test tube within 30 seconds, it is considered that a sol-gel phase transition has occurred. figure 2 Is the sol-gel phase transition temperature chart measured by the vial inversion method.

Embodiment 3

[0049] When the polymer aqueous solution undergoes a phase transition, the changes in the storage modulus and loss modulus with temperature can be observed in the rheology, and the temperature-sensitive properties and mechanical properties of the hydrogel can be described in detail. Using variable temperature mode, the deformation is 1%, the alternating stress is 1Hz, and the heating rate is 1℃·min -1 The temperature range is 15°C-60°C. Under such test conditions, a rotary rheometer is used to characterize the rheological properties of the polymer aqueous solution configured in Example 2 with temperature changes. image 3 It is the rheogram of the block copolymer aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com