Waterless cleaning device for solar cell panel

A technology for a solar cell panel and a cleaning device, which is applied to cleaning methods and utensils, a cleaning method using tools, a cleaning method using gas flow, etc., can solve the problems of high labor intensity, expensive cleaning equipment, complicated operation, etc. The effect of high cleaning efficiency and saving cleaning and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] All features or steps in all methods or processes disclosed in this specification can be combined in any way except for mutually exclusive features and processes.

[0024] The method and the best embodiment will be further described in detail according to the accompanying drawings.

[0025] For ease of description, terms such as "upper," "lower," "left," and "right" are used herein to refer to the relationship of one component or feature to another as shown in the drawing figures, except that In addition to those shown in , the terms "upper", "lower", "front", "rear", "longitudinal" and "transverse" refer to a part in a solar panel array or called a photovoltaic array. s position.

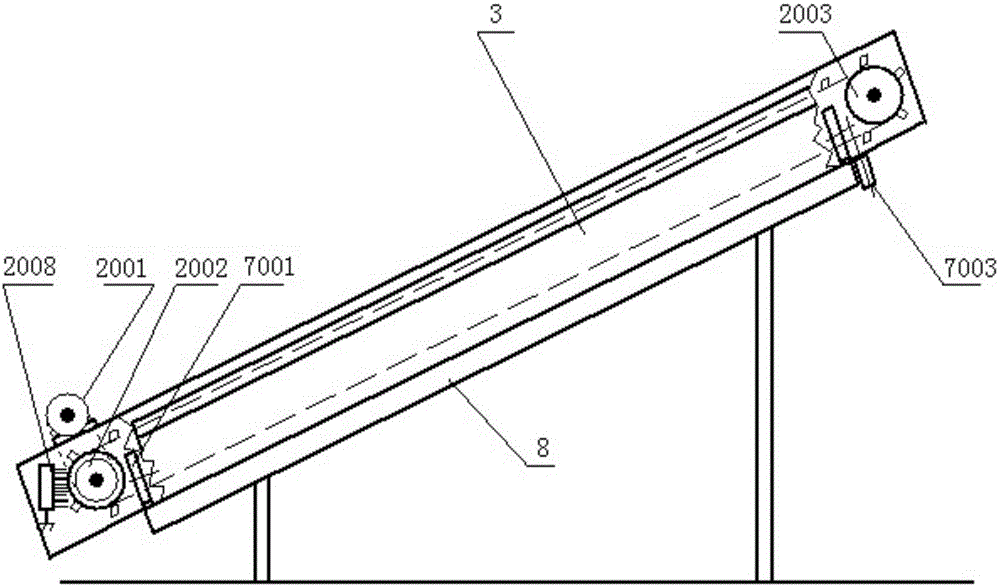

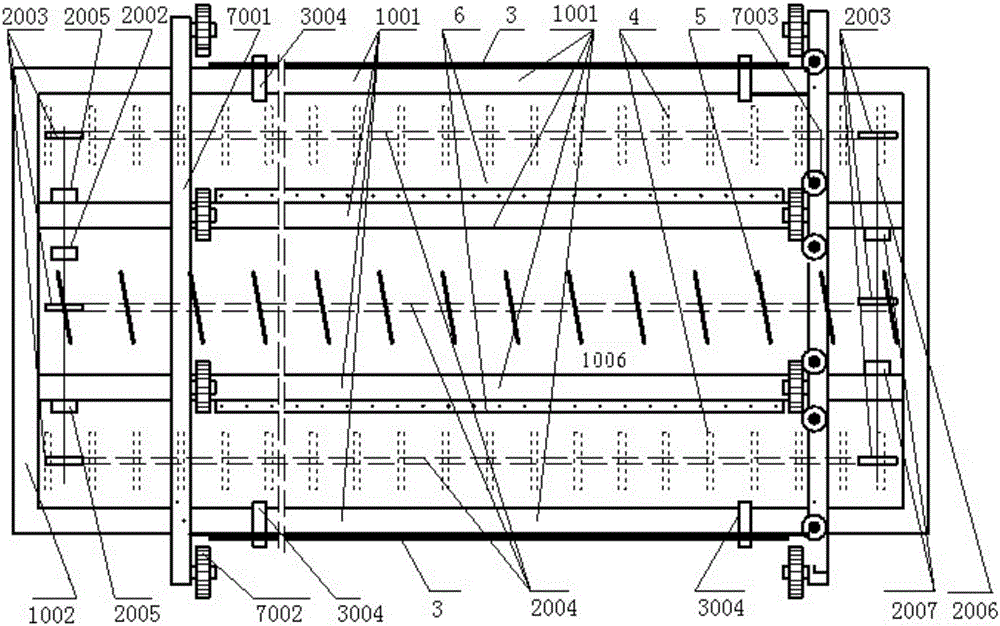

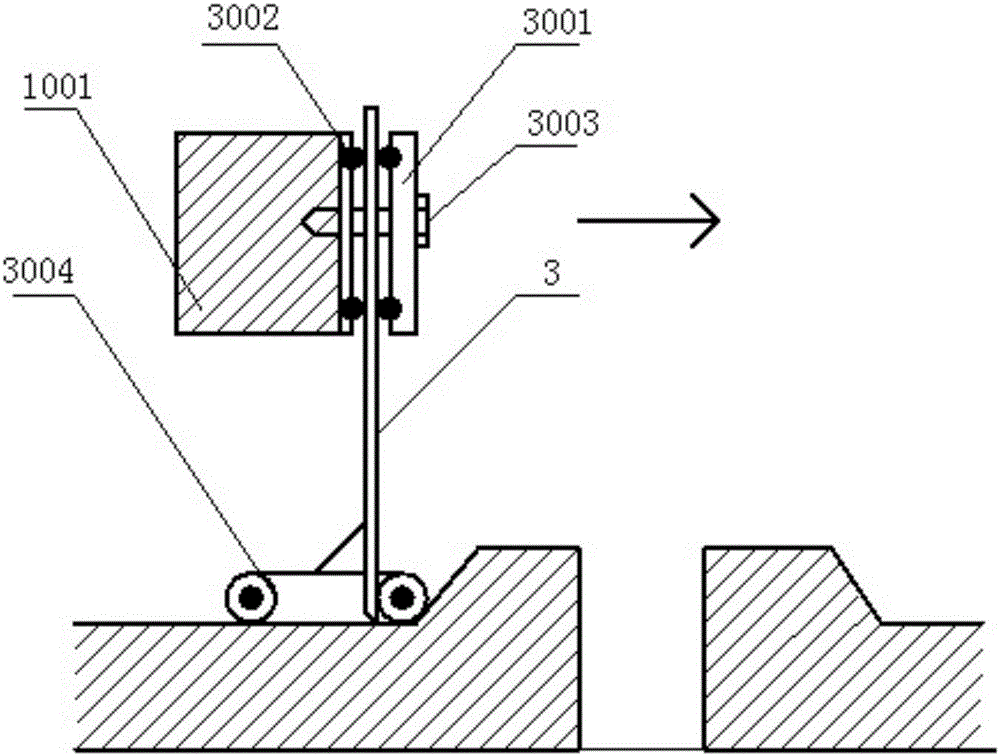

[0026] The structure of the solar panel water-free cleaning device of the present invention is as follows: figure 1 As shown, it includes a frame, the frame includes a long frame rod 1001 and a short frame rod 1002, the frame is driven by an external force or its own walking mechanism, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com