Inorganic-based neutralization-proof, water-proof, and erosion-proof paint composition for floor finish material, capable of being applied, without primer, in wet state with concrete water content of 100%, and method for applying neutralization-proof, water-proof, and erosion-proof flooring material, using composition

A wet state, decorative material technology, applied in the direction of sustainable waste treatment, floors, building structures, etc., can solve the problems of no permeability, low moisture resistance when applied, blisters, etc., to achieve excellent water resistance, anti-corrosion The effect of wheel friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

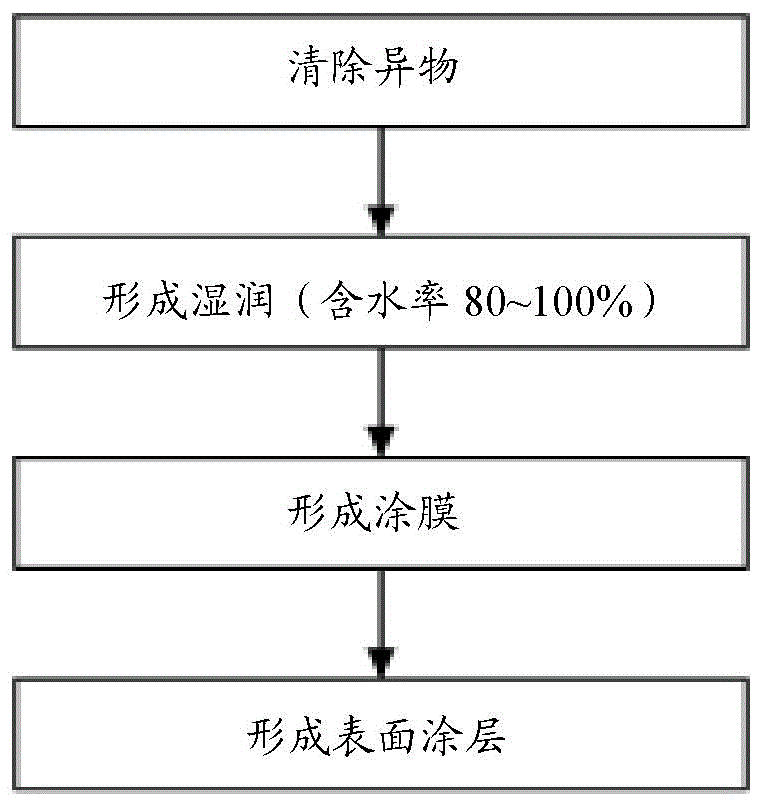

Method used

Image

Examples

Embodiment 1

[0103] At this time, the inorganic powder consists of 100 parts by weight of cementitious material powder (white cement: blast furnace slag particles 1:1 by weight), 60 parts by weight of silicon powder (400 mesh), 15 parts by weight of inorganic pigment (zinc oxide), 2 parts by weight of alumina cement, 0.5 parts by weight of PC (Polycarboxylate) dispersant, 0.3 parts by weight of powder defoamer (trade name: defoma), 0.2 parts by weight of surface stabilizer (trade name: ONICELL), 0.1 part by weight of bentonite, The curing conditions are a temperature of 18-25°C and an air humidity of about 80%.

[0104] Example 2

Embodiment 2

[0106] Apply the inorganic coating composition on the surface of the concrete structure (moisture content 100%) with a size of 5 x 5 m and a thickness of 1 to 3 mm, and then check whether the coating film is formed and cracked after 24 hours [Table 1 ] to display the result.

[0107] At this time, the inorganic powder consists of 100 parts by weight of cementitious material powder (white cement: blast furnace slag particles 1:1 ratio), 60 parts by weight of silicon powder (400 mesh), 15 parts by weight of inorganic pigment (zinc oxide), 2 parts by weight Bauxite cement, 0.5 parts by weight of PC (Polycarboxylate) dispersant, 0.3 parts by weight of powder defoamer (trade name: defoma), 0.2 parts by weight of surface stabilizer (trade name: ONICELL), 0.1 parts by weight of bentonite, the curing conditions are 18 ~ 25 ℃ temperature and about 80% air humidity.

[0108] Example 3

Embodiment 3

[0110] Apply the inorganic coating composition on the surface of the concrete structure (moisture content 100%) with a size of 5 x 5 m and a thickness of 3 to 5 mm, and then check whether the coating film is formed and cracked after 24 hours [Table 1 ] to display the result.

[0111]At this time, the inorganic powder consists of 100 parts by weight of cementitious material powder (white cement: blast furnace slag particles 1:1 ratio), 60 parts by weight of silicon powder (400 mesh), 15 parts by weight of inorganic pigment (zinc oxide), 2 parts by weight Bauxite cement, 0.5 parts by weight of PC (Polycarboxylate) dispersant, 0.3 parts by weight of powder defoamer (trade name: defoma), 0.2 parts by weight of surface stabilizer (trade name: ONICELL), 0.1 parts by weight of bentonite, the curing conditions are 18 ~ 25 ℃ temperature and about 80% air humidity.

[0112] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com