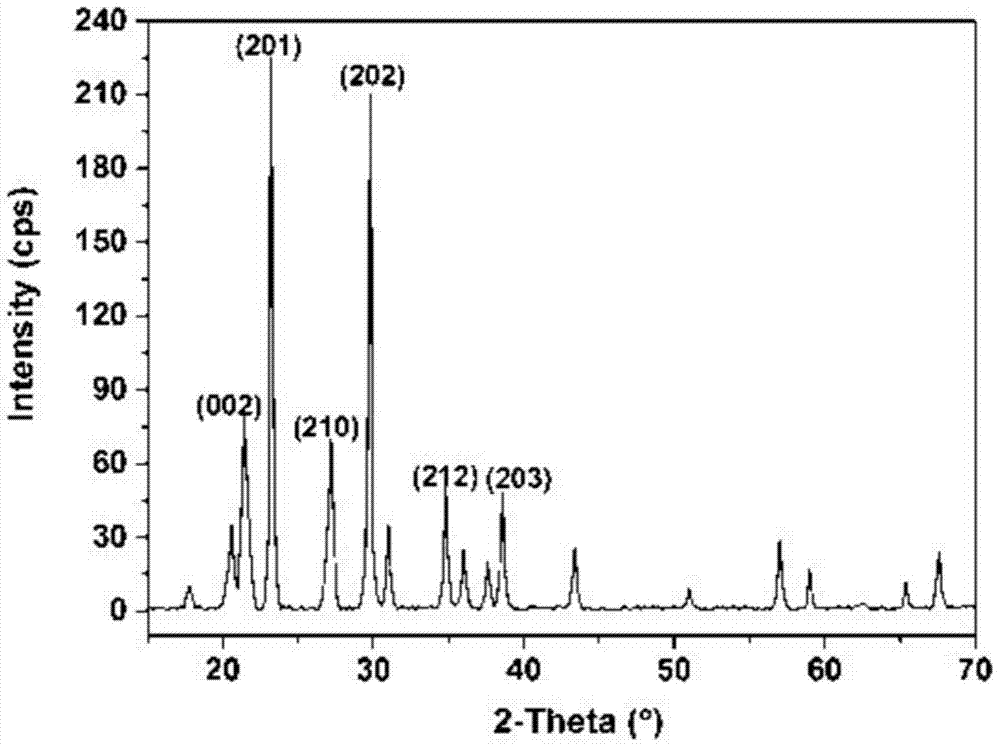

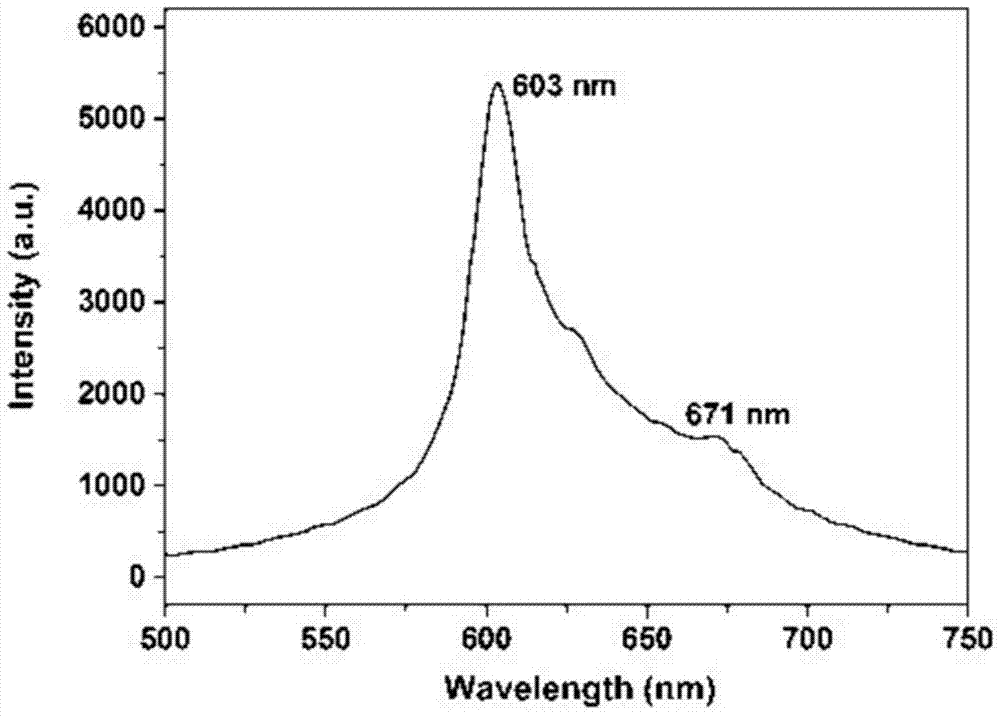

A malsio for led 4 :pr 3+ Preparation method of red phosphor

A red light phosphor powder and the obtained technology are applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., and can solve the problems of uneven particle size of phosphor particles, uneven mixing of activators, affecting mixing uniformity, etc. , to achieve the effect of uniform particle size distribution, uniform dispersion and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 This embodiment discloses a kind of MASiO for LED 4 : Pr 3+ The preparation method of red light phosphor, concrete steps are as follows:

[0029] (1) Weigh 4.502g of Al(NO 3 ) 3 9H 2 O particles are placed in a high-pressure container (the volume of the high-pressure container is 80mL, the material is a polytetrafluoroethylene liner, a stainless steel shell, and the pressure range is 0-10Mpa), and the filling ratio is 30% (referring to the ratio of the volume of the solvent to the volume of the high-pressure container) ), C 2 h 5 O (absolute ethanol): H 2 O (distilled water) = 0.25:1 volume ratio, add 4.8mL of C into the pressure vessel 2 h 5 O and 19.2 mL of H 2 O, to be Al(NO 3 ) 3 9H 2 After the O particles are fully dissolved, Al(NO 3 ) 3 solution (referring to Al 3+ accounted for C 2 h 5 O and H 2 O the concentration of the total volume of the mixed solution);

[0030] (2) According to the molar ratio of K:Al:Si=1:1:1, weigh 1.201g o...

Embodiment 2

[0035] Embodiment 2 This embodiment discloses a kind of MASiO2 for LED 4 : Pr 3+ The preparation method of red light phosphor, concrete steps are as follows:

[0036] (1) Weigh 6.302g of Al(NO 3 ) 3 9H 2 O particles are placed in a high-pressure container (the volume of the high-pressure container is 80mL, the material is a polytetrafluoroethylene lining, a stainless steel shell, and the pressure range is 0-10Mpa), and the filling ratio is 60% (referring to the ratio of the volume of the solvent to the volume of the high-pressure container) ), C 2 h 5 O (absolute ethanol): H 2 O (distilled water) = 0.2:1 volume ratio, add 8mL of C into the pressure vessel 2 h 5 O and 40 mL of H 2 O, to be Al(NO 3 ) 3 9H 2 After the O particles are fully dissolved, Al(NO 3 ) 3 solution (referring to Al 3+ accounted for C 2 h 5 O and H 2 O the concentration of the total volume of the mixed solution);

[0037] (2) According to the molar ratio of Li:Na:Al:Si=0.5:0.5:1:1, weigh ...

Embodiment 3

[0042] Embodiment 3 This embodiment discloses a kind of MASiO for LED 4 : Pr 3+ The preparation method of red light phosphor, concrete steps are as follows:

[0043] (1) Weigh 3.001g of Al(NO 3 ) 3 9H 2 O particles are placed in a high-pressure container (the volume of the high-pressure container is 80mL, the material is polytetrafluoroethylene lining, stainless steel shell, and the pressure range is 0-10Mpa), and the filling ratio is 50% (referring to the ratio of the volume of the solvent to the volume of the high-pressure container) ), C 2 h 5 O (absolute ethanol): H 2 O (distilled water) = 0.29:1 volume ratio, add 9mL of C into the pressure vessel 2 h 5 O and 31 mL of H 2 O, to be Al(NO 3 ) 3 9H 2 After the O particles are fully dissolved, Al(NO 3 ) 3 solution (referring to Al 3+ accounted for C 2 h 5 O and H 2 O the concentration of the total volume of the mixed solution);

[0044] (2) According to the molar ratio of K:Al:Si=1:1:1, weigh 0.801g of KHCO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com