Antimony-doped tin oxide-carbon nanotube compounded adsorptive electrode and preparation method thereof

A carbon nanotube composite, tin dioxide technology, applied in chemical instruments and methods, oxidized water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of low electrocatalytic efficiency, short electrode life, etc. Longevity and the effect of enhancing electrocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

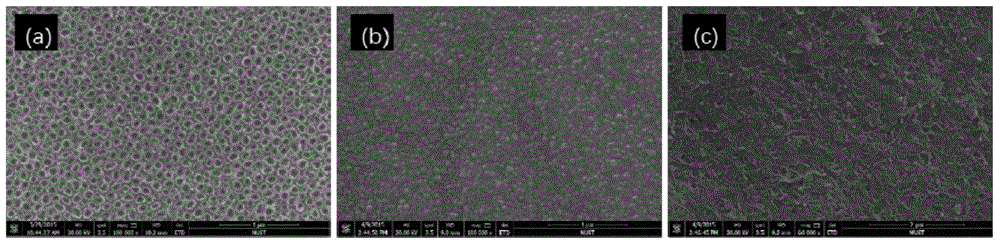

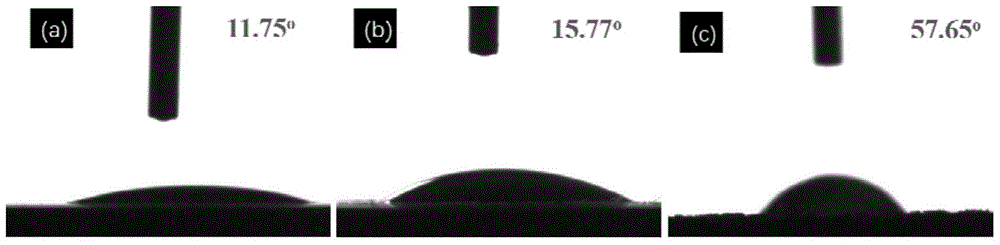

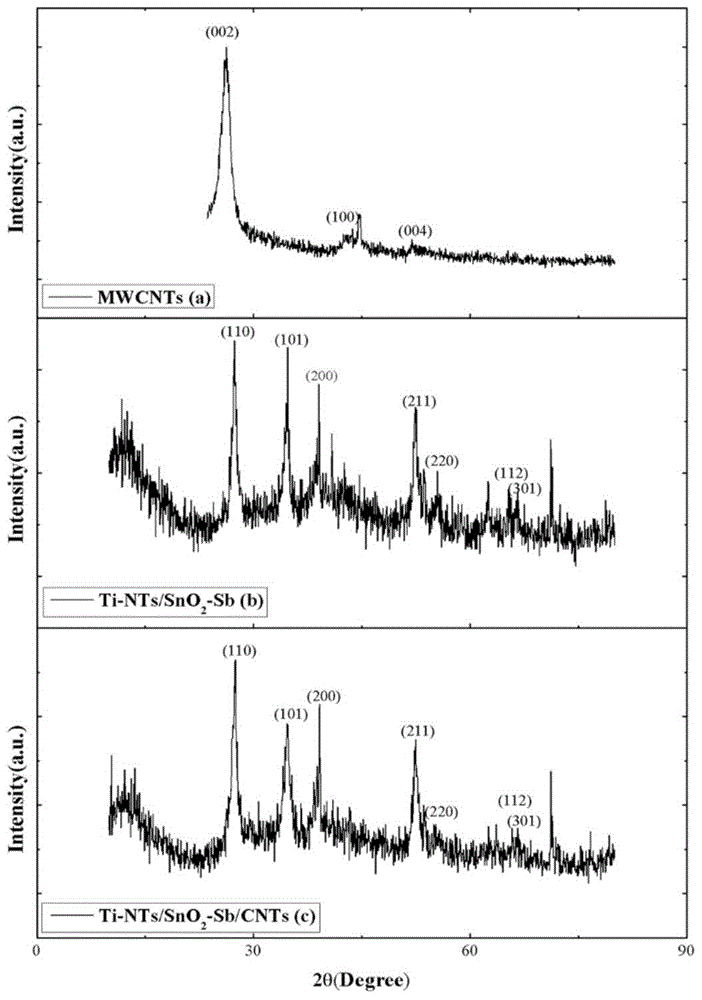

[0026] Cut the titanium plate into a size of 1.0cm×3.0cm, and polish the titanium surface with sandpaper until it is smooth; ultrasonically clean the surface to remove oil; then heat in 18% hydrochloric acid solution for 20min to remove the oxide layer; finally put it in deionized water for later use. The treated titanium plate is used as the anode, and the stainless steel plate of the same size is used as the cathode. The control plate is immersed in the electrolyte solution for 2cm, and the distance between the plates is 1.0cm. At the same time, it is stirred rapidly with a magnetic stirrer. Aqueous solution of mol / L potassium fluoride and 0.95mol / L sulfuric acid, control the operating voltage at 20V, take it out after anodizing for 70min, rinse with deionization, and heat up to 500°C at a rate of 1°C / min in a muffle furnace after drying ℃, calcined for 3 hours, and naturally cooled to room temperature to prepare the titanium dioxide nanotube array matrix.

[0027] The titan...

Embodiment 2

[0034] Cut the titanium plate into a size of 1.0cm×3.0cm, and polish the titanium surface with sandpaper until it is smooth; ultrasonically clean the surface to remove oil; then heat in 18% hydrochloric acid solution for 20min to remove the oxide layer; finally put it in deionized water for later use. The treated titanium plate is used as the anode, and the stainless steel plate of the same size is used as the cathode. The control plate is immersed in the electrolyte solution 2cm, and the distance between the plates is 1.0cm. At the same time, it is stirred rapidly with a magnetic stirrer. mol / L sodium fluoride and 1.05mol / L sulfuric acid aqueous solution, control the operating voltage to 20V, take it out after anodizing for 60min, rinse with deionization, and heat up to 450 at a rate of 2°C / min in a muffle furnace after drying ℃, calcined for 5 hours, and naturally cooled to the room to prepare the titanium dioxide nanotube array matrix.

[0035] The titanium-based titanium dio...

Embodiment 3

[0038] The antimony-doped tin dioxide-carbon nanotube composite adsorptive electrode (Ti-NTs / SnO 2 -Sb / CNTs) and titanium-based tin dioxide electrodes (TiO 2 / SnO 2 -Sb) Electrocatalytic degradation effect on phenol (Phenol).

[0039] Prepare 100mL of BA simulated wastewater with a concentration of 100mg / L, and add 0.1M Na 2 SO 4 As the electrolyte, Ti-NTs / SnO 2 -Sb / CNTs and TiO 2 / SnO 2 -Sb electrode as anode, stainless steel as cathode, control current density 30mA / cm 2 , to compare the electrocatalytic oxidation performance of two electrodes for phenol.

[0040] Figure 5 Ti-NTs / SnO of the present invention 2 -Sb / CNTs electrode and TiO 2 / SnO 2 -Sb electrode degradation of phenol removal rate change with the reaction time. It can be seen from the figure that after electrolysis for 3h, Ti-NTs / SnO 2 -Sb / CNTs electrode and TiO 2 / SnO 2 -Sb electrodes have phenol removal rates of 83.2% and 65.7%, respectively, indicating that the prepared Ti-NTs / SnO 2 -Sb / CNTs e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com