Method capable of improving acid resistance during reverse extraction of extraction agent containing pyridine carboxylic ester and dinonylnaphthalene sulfonic acid and application of method

A technology of dinonylnaphthalene sulfonic acid and pyridine carboxylate, which is applied in the field of metallurgical extraction of non-ferrous metals, can solve the problems of inability to separate phases in back extraction, poor acid resistance of extraction agents, and long time for back extraction and phase separation, so as to avoid phase separation If the time is too long, the effect of improving acid resistance and shortening the time of stripping and phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Fix the acid concentration (H + Concentration is 1.0mol / L of sulfuric acid or hydrochloric acid solution), investigate the impact of the amount of TOPO added on the acid resistance of the extractant during back extraction.

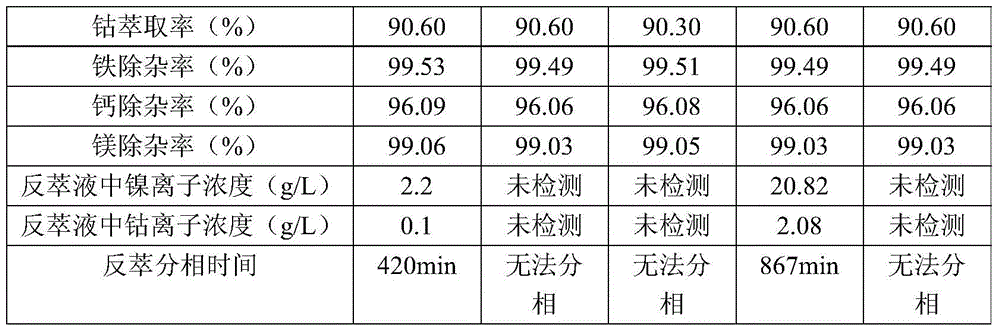

[0033] To containing pyridine carboxylate (0.9mol / L) and dinonyl naphthalene sulfonic acid (0.45mol / L) extractant, add TOPO (having the mol ratio of TOPO involved in the "summary of the invention" and dinonyl naphthalene sulfonic acid The range is 1:1~3:1), using sulfonated kerosene as a diluent to prepare the extractant (ie oil phase). Preparation of cobalt, nickel acidic solution (i.e. extracted water phase) containing impurities such as iron, calcium and magnesium, wherein Ni 2+ The concentration is 2.5~4.0g / L, Co 2+ The concentration is 0.25~0.28g / L, Fe 3+ The concentration is 9.8~10.0g / L, Mg 2+ The concentration is 4.5~5.17g / L, Ca 2+The concentration is 0.2-0.25g / L, and the pH value is about 2. Extraction operation: Add 50ml of the oil ph...

Embodiment 2

[0039] Add TOPO to the extractant containing pyridine carboxylate (0.9mol / L) and dinonylnaphthalenesulfonic acid (0.45mol / L), keep the molar ratio of TOPO and DNNSA at 2:1, and investigate the effect of the acidity of the stripping agent on the extractant The impact of acid resistance during stripping.

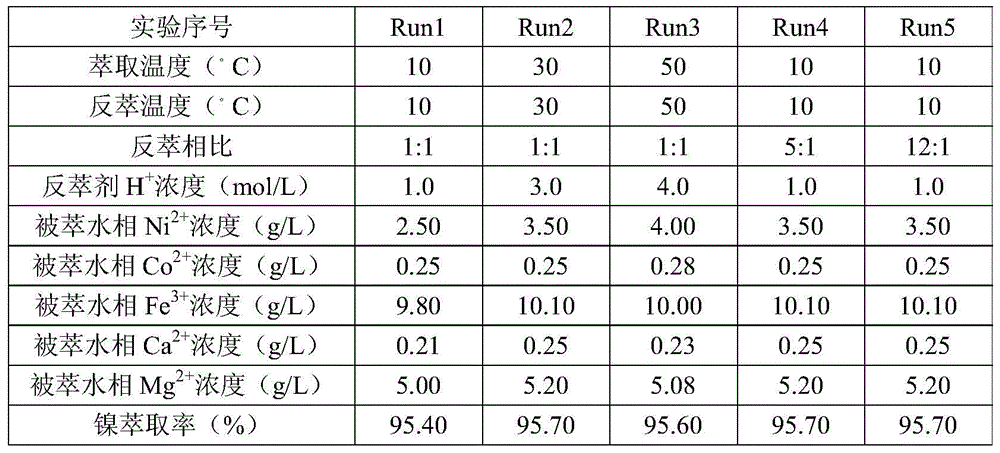

[0040] Add TOPO (the molar ratio of TOPO to dinonylnaphthalenesulfonic acid is 2:1) to the pyridine carboxylate (0.9mol / L) and dinonylnaphthalenesulfonic acid (0.45mol / L), using sulfonated kerosene As a diluent, it is prepared as an extractant (ie oil phase). Preparation of cobalt, nickel acidic solution (i.e. extracted water phase) containing impurities such as iron, calcium and magnesium, wherein Ni 2+ Concentration is 2.5~3.5g / L, Co 2+ The concentration is 0.25g / L, Fe 3+ The concentration is 9.8~10.1g / L, Mg 2+ The concentration is 5.0~5.2g / L, Ca 2+ The concentration is 0.2-0.25g / L, and the pH value is about 2. Extraction operation: Add 50ml of the oil phase and the ex...

Embodiment 3

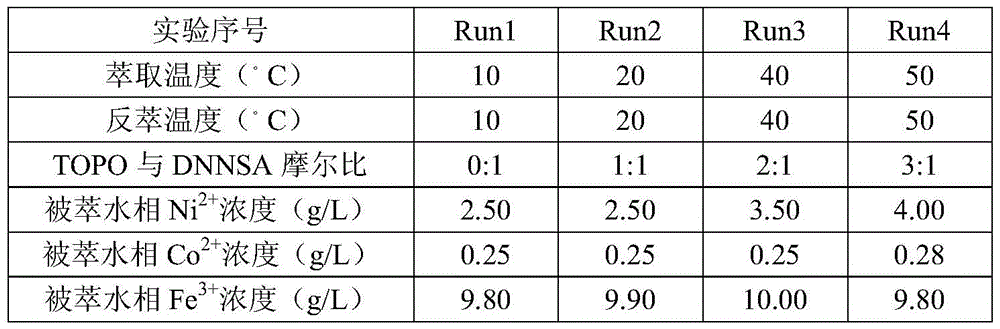

[0046] Add TOPO to the extractant containing pyridine carboxylate and dinonylnaphthalenesulfonic acid, keep the molar ratio of TOPO and DNNSA at 2:1, and fix the stripping agent as H + Sulfuric acid or hydrochloric acid solution with a concentration of 1.0mol / L was used to investigate the effect of the relative amount of pyridine carboxylate and dinonylnaphthalenesulfonic acid on the extraction rate of cobalt nickel metal ions and the removal rate of iron, calcium and magnesium impurities.

[0047] Add TOPO (TOPO The molar ratio to dinonylnaphthalene sulfonic acid is 2:1), using sulfonated kerosene as a diluent to prepare the extractant (ie, the oil phase). Preparation of cobalt, nickel acidic solution (i.e. extracted water phase) containing impurities such as iron, calcium and magnesium, wherein Ni 2+ The concentration is 2.5~4.0g / L, Co 2+ The concentration is 0.25~0.28g / L, Fe 3+ The concentration is 9.8~10.1g / L, Mg 2+ The concentration is 5.0~5.2g / L, Ca 2+ The concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com