A kind of photocuring material and its preparation method and application

A technology of light-curing materials and printing materials, which is applied in the chemical industry, can solve the problems of relying on foreign imports of molding resins, few materials suitable for light-curing, and high prices of molding materials, and achieve moderate curing strength and flexibility, small curing shrinkage, and high hardness. and moderate flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

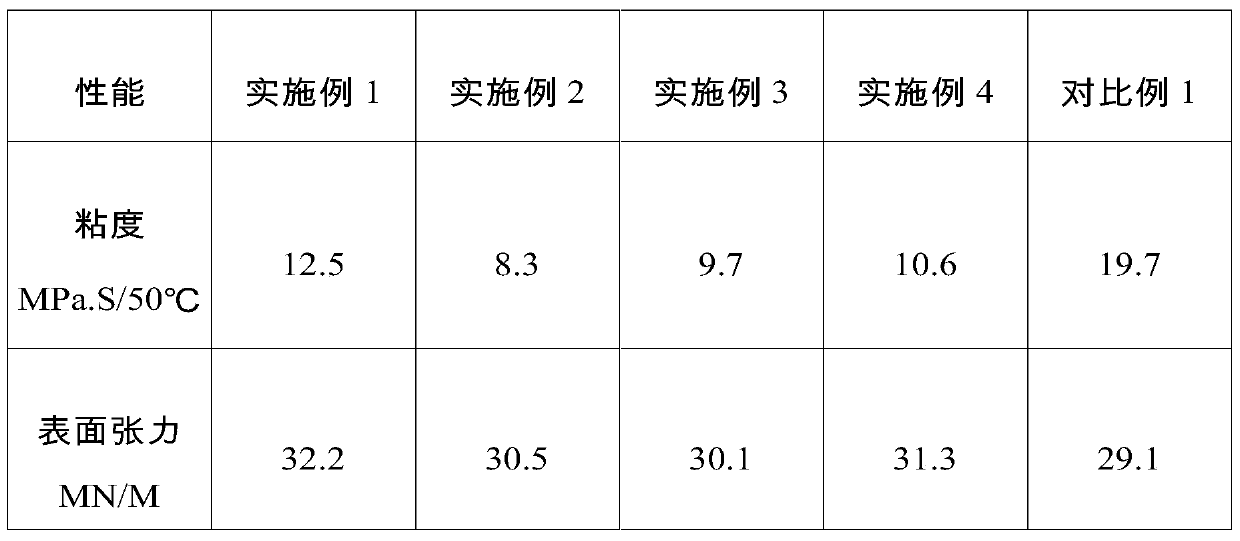

Examples

Embodiment 1

[0044] 1. Preparation of photocurable materials

[0045]Main resin:

[0046] Polyethylene glycol diacrylate (PEGDA): 30%;

[0047] Dicyclohexylmethane diisocyanate belongs to cycloaliphatic diisocyanate: 40%;

[0048] Photoinitiator:

[0049] BP: 1%;

[0050] TPO: 1.5%

[0051] Active diluent

[0052] Tripropylene glycol diacrylate: 8%

[0053] Pure acrylic resin: 6.5%

[0054] Auxiliary:

[0055] Ethanol: 5%;

[0056] Dimethicone: 4%

[0057] Polyacrylate: 4%;

[0058] Add the above raw materials into the reactor, stir to dissolve, and then vigorously stir at 40°C for 6 hours. After the stirring is completed, let it stand for cooling and filter to obtain a photocurable material, that is, a photocurable resin binder.

[0059] 2. Preparation of zirconia printing materials

[0060] Add 92% by weight of zirconia powder and 8% of the light-curable material prepared in step 1 into the mixer.

[0061] Turn on the mixer, mix and grind the above two raw materials at a spe...

Embodiment 2

[0064] 1. Preparation of photocurable materials

[0065] Main resin:

[0066] Polyethylene glycol diacrylate (PEGDA): 25%;

[0067] Dicyclohexylmethane diisocyanate belongs to cycloaliphatic diisocyanate: 30%;

[0068] Photoinitiator:

[0069] BP: 2%;

[0070] TPO: 3%

[0071] Active diluent

[0072] Tripropylene glycol diacrylate: 10%

[0073] Pure acrylic resin: 10%

[0074] Auxiliary:

[0075] Ethanol: 8%;

[0076] Dimethicone: 6%

[0077] Polyacrylate: 6%;

[0078] Add the above raw materials into the reactor, stir to dissolve, and then vigorously stir at 40°C for 6 hours. After the stirring is completed, let it stand for cooling and filter to obtain a photocurable material, that is, a photocurable resin binder.

[0079] 2. Preparation of zirconia printing materials

[0080] Add 90% by weight of zirconia powder and 10% of the photocurable material prepared in step 1 into the mixer.

[0081] Turn on the mixer, mix and grind the above two raw materials at a spee...

Embodiment 3

[0084] 1. Preparation of photocurable materials

[0085] Main resin:

[0086] Polyethylene glycol diacrylate (PEGDA): 35%;

[0087] Dicyclohexylmethane diisocyanate is an alicyclic diisocyanate: 45%;

[0088] Photoinitiator:

[0089] BP: 0.5%;

[0090] TPO: 0.5%

[0091] Active diluent

[0092] Tripropylene glycol diacrylate: 5%

[0093] Pure acrylic resin: 5%

[0094] Auxiliary:

[0095] Ethanol: 4%;

[0096] Dimethicone: 2%

[0097] Polyacrylate: 3%;

[0098] Add the above raw materials into the reactor, stir to dissolve, and then vigorously stir at 40°C for 6 hours. After the stirring is completed, let it stand for cooling and filter to obtain a photocurable material, that is, a photocurable resin binder.

[0099] 2. Preparation of zirconia printing materials

[0100] Add 95% by weight of zirconia powder and 5% of the photocurable material prepared in step 1 into the mixer.

[0101] Turn on the mixer, mix and grind the above two raw materials at a speed of 200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com