Ignition bridge with lattice-shaped energy-containing thin film

A grid-shaped, ignition bridge technology, applied in the direction of offensive equipment, fuzes, etc., can solve the problems of heat energy and plasma not being concentrated in the vertical direction, slowing down the rate of energy vertical diffusion, reducing energy utilization and conversion efficiency, etc., to achieve Improve energy utilization and energy conversion efficiency, reduce energy diffusion and loss, and accelerate the diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

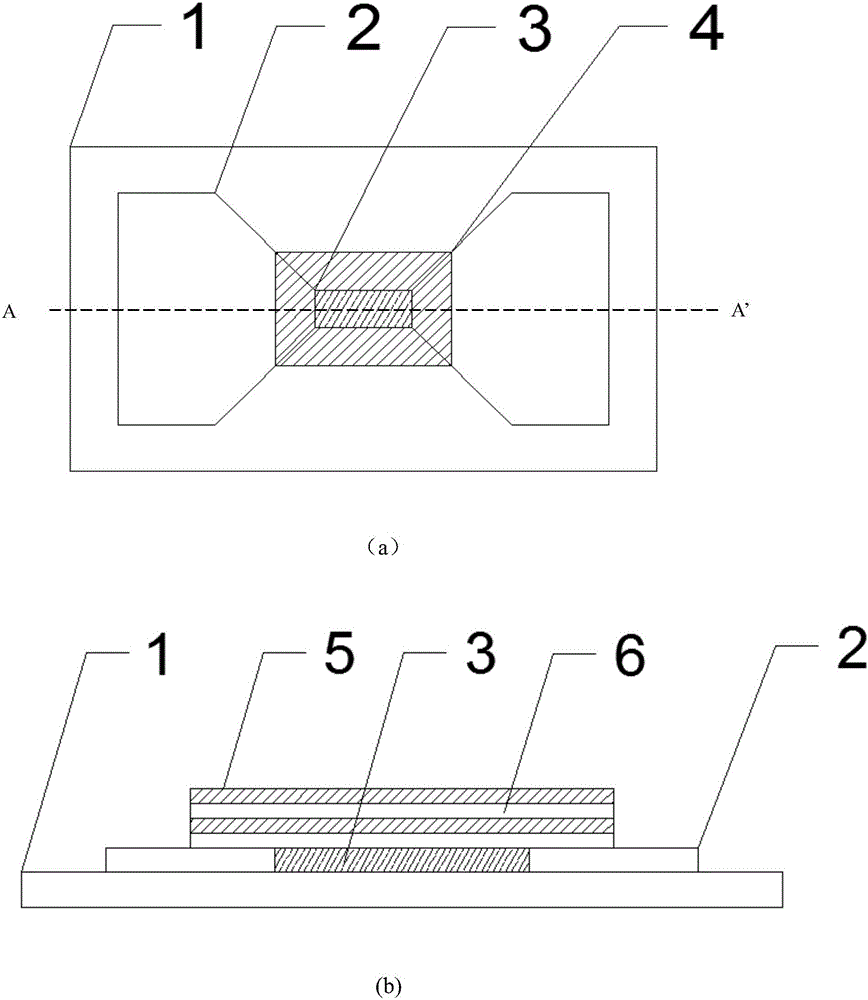

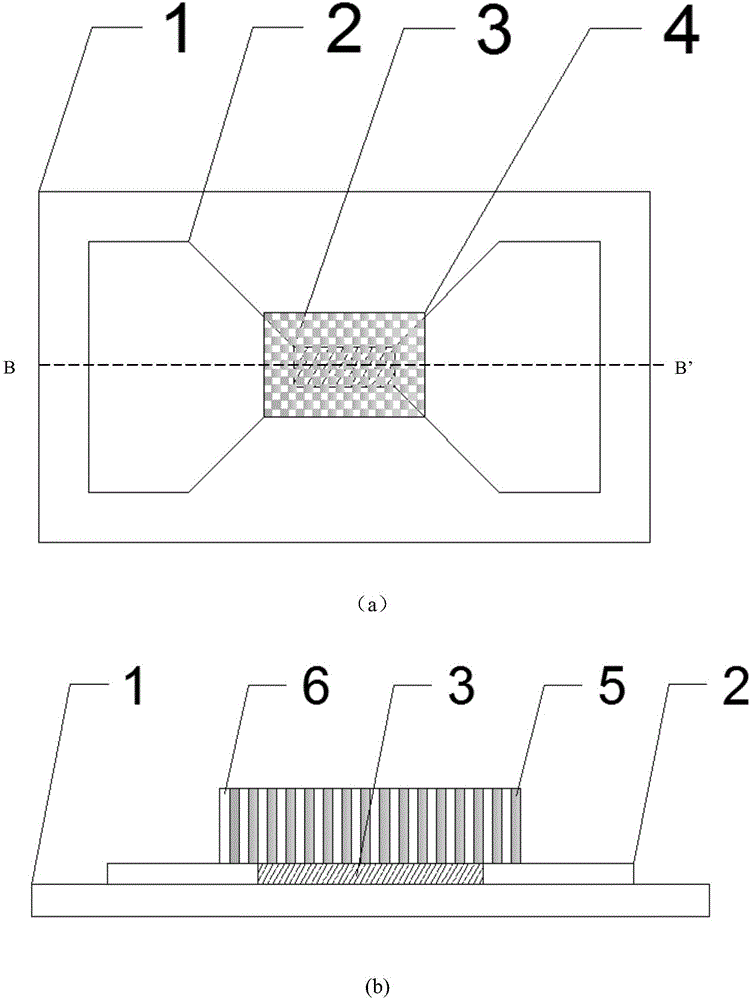

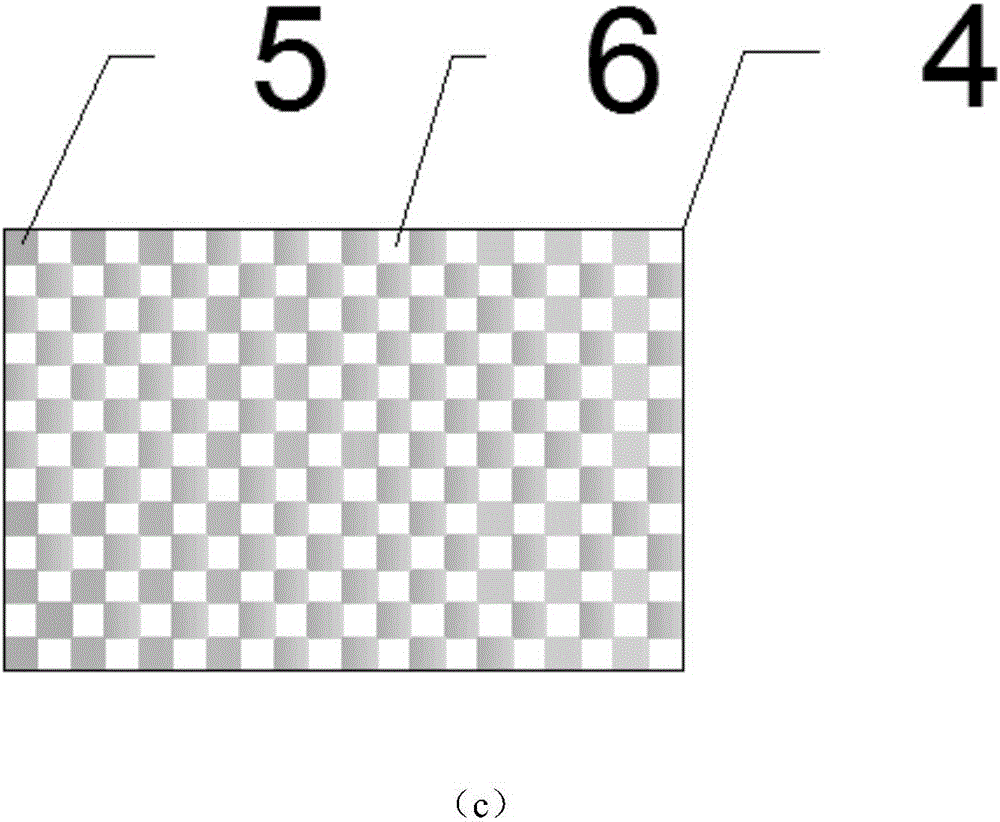

[0027] A grid-shaped energetic thin film ignition bridge, comprising an alumina ceramic substrate, a copper electrode positioned on the alumina ceramic substrate and a platinum ignition bridge region, and an energetic thin film layer positioned on the platinum ignition bridge region, said The energetic thin film layer is Al / PTFE, and the thickness of the energetic thin film layer is 2 μm. The energetic thin film layer has a grid-like structure, and the shape of a single grid is square, with a side length of 100 nanometers.

[0028] The preparation method of the above-mentioned grid-like energetic thin film ignition bridge comprises the following steps:

[0029] Step 1. Cleaning of the substrate: select an alumina ceramic substrate with a size of 3 inches as the base of the ignition bridge; ultrasonically clean the alumina ceramic substrate in acetone, alcohol, and deionized water for 10 minutes, and dry;

[0030] Step 2. Electrode preparation: put the cleaned and dried substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com