Doped and mixed nanophase material and preparation method and application thereof

A technology of nanophase and powder materials, applied in the field of materials science, can solve the problems of unfavorable large-scale production and high cost, and achieve the effect of small particle size, good conductivity and concentrated particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 of the present invention provides a kind of preparation method of mixing nano-phase silicon material, and described method comprises the following steps:

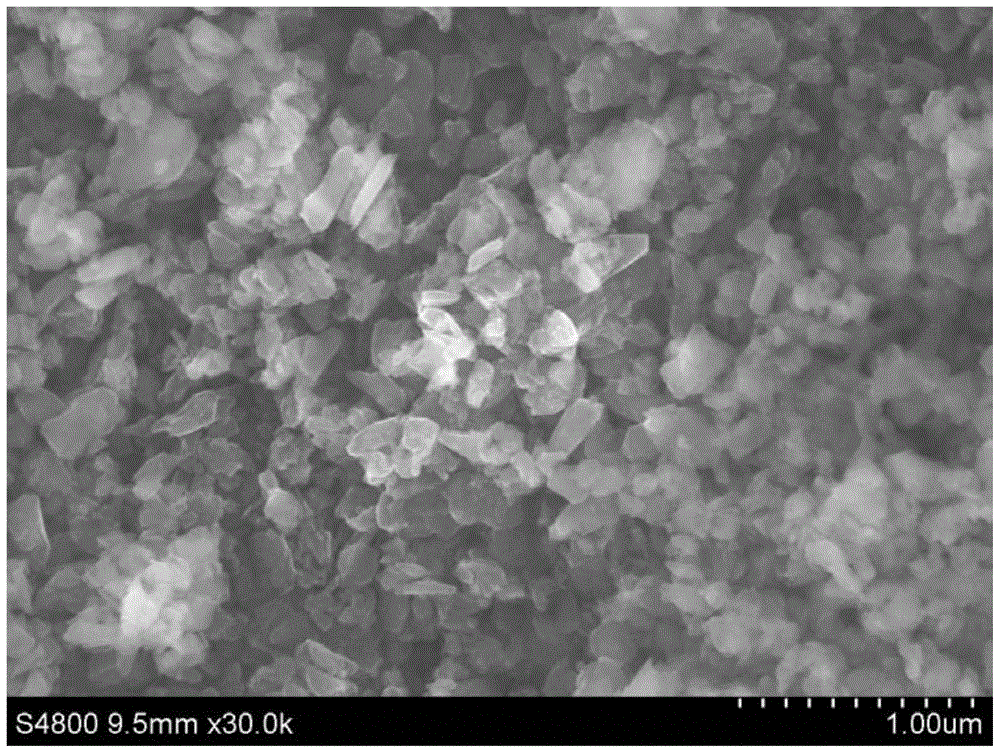

[0031] Add silicon powder materials with a particle size of 5 μm to ethylene glycol at a solid content of 20%, and at the same time add boron oxide and dodecylbenzenesulfonic acid to ethylene glycol, disperse evenly at high speed, and dry , added to a ball mill for initial grinding, after initial grinding for 2 hours, added to a circulating grinder or a high-energy ball mill containing zirconia balls with a particle size of 0.1mm for fine grinding at a temperature of 50°C, and finely ground for 10 hours, except After magnetization, a homogeneously mixed nano-phase silicon material with a particle size of 150nm is prepared, such as figure 1 shown.

[0032] The method provided in this embodiment is simple, easy to implement, low in cost, and suitable for applications that can be manufactured on a large sc...

Embodiment 2

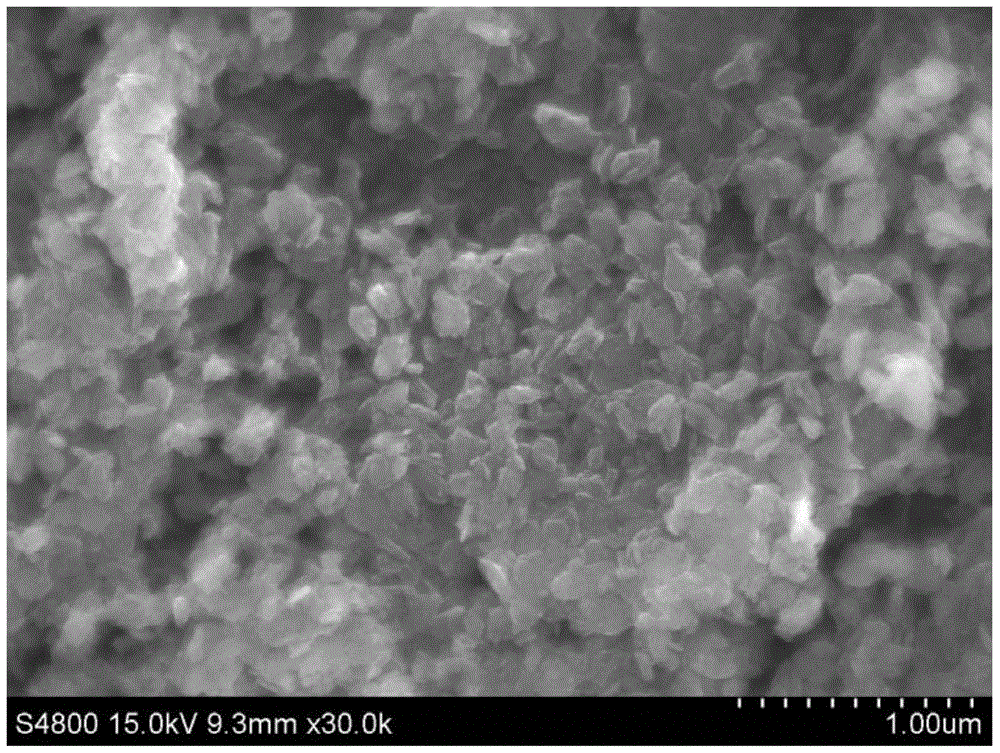

[0034] Embodiment 2 of the present invention provides a kind of preparation method of mixing nano-phase silicon material, described method comprises the following steps:

[0035] Add silicon powder materials with a particle size of 5 μm to ethylene glycol at a solid content of 20%, and at the same time add boron oxide and dodecylbenzenesulfonic acid to ethylene glycol, disperse evenly at high speed, and dry , added to a ball mill for initial grinding, after initial grinding for 2 hours, added to a circulating grinder or a high-energy ball mill containing zirconia balls with a particle size of 0.1mm for fine grinding, at a temperature of 50°C, for 20 hours of fine grinding, except After magnetization, a mixed nano-phase silicon material with a particle size of 100nm is prepared, such as figure 2 shown.

Embodiment 3

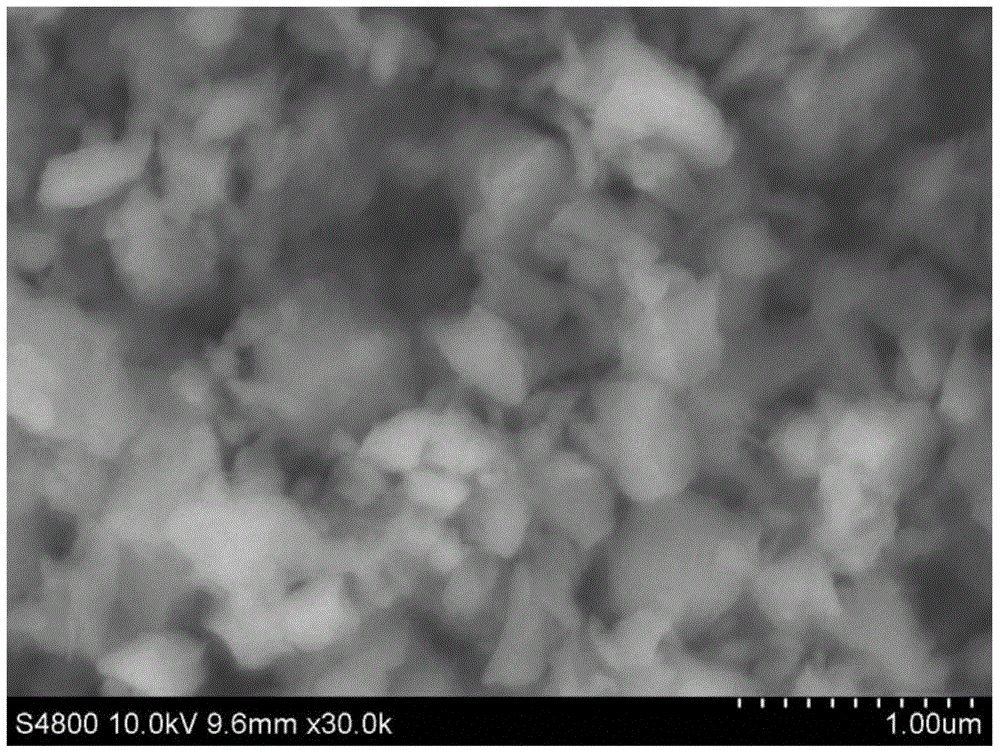

[0037] Embodiment 3 of the present invention provides a kind of preparation method of mixing nano-phase silicon material, described method comprises the following steps:

[0038] Add silicon powder materials with a particle size of 100nm to ethylene glycol at a solid content of 20%, and at the same time add boron oxide and dodecylbenzenesulfonic acid to the solvent, disperse evenly at high speed, and after drying, add Put it into a ball mill for initial grinding. After 2 hours of initial grinding, add it to a circulating grinder or a high-energy ball mill containing zirconia balls with a particle size of 0.5mm for fine grinding at a temperature of 50°C for 2 hours. After demagnetization , to prepare a mixed nano-phase silicon material with a particle size of 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com