Low-alkalinity flotation separation method for pyrite activated by Cu2+ and chalcocite

A separation method and low alkalinity technology, applied in flotation, solid separation and other directions, can solve the problems of pyrite inhibition, chalcocite easy to be oxidized, increase grinding cost, etc. The effect of reducing the pH value of flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

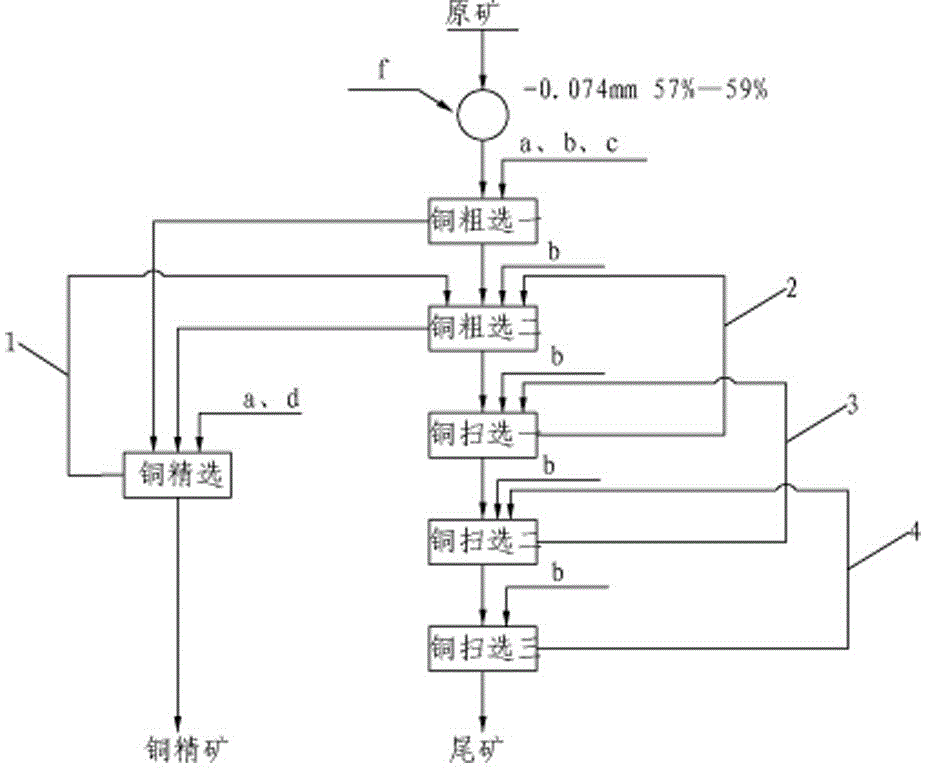

Method used

Image

Examples

Embodiment 1

[0020] Copper minerals in a copper ore in Fujian mainly exist in the form of bluechalcocite, copper blue, chalcocite, and chalcocite, and most of the gangue minerals are quartz, followed by dickite, kaolinite, polyhydric Kaolinite, and a small amount of alunite, chlorite, barite, and calcite. The multi-element analysis results are shown in Table 1.

[0021] Table 1 Example 1 Raw ore multi-element chemical analysis results / %

[0022] project

Cu

S

TF

Au*

Ag*

As

Zn

CaO

SiO 2

Al 2 o 3

content

0.59

4.02

2.23

0.22

7.40

0.078

<0.01

0.12

70.66

9.70

[0023] Note: The sulfur in the multi-element analysis results is available sulfur, that is, the sulfur contained in pyrite and pyrrhotite, *unit is g / t, the same below.

[0024] The recovery method of copper ore includes the following steps:

[0025] A: Low-alkalinity copper roughing: add lime f1500g / ton to the raw ore for grinding,...

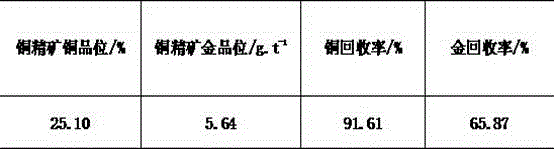

Embodiment 2

[0032] Copper minerals in a copper ore in Xinjiang mainly exist in the form of blue chalcocite, copper blue, chalcocite and chalcocite, most of the gangue minerals are quartz, followed by dickite, kaolinite, polyhydric Kaolinite, and a small amount of alunite, chlorite, barite, and calcite. The multi-element analysis results are shown in Table 3.

Embodiment 3

[0033] Table 3 Example 3 raw ore multi-element chemical analysis results / %

[0034] project

Cu

S

TF

Au*

Ag*

As

P 2 o 5

CaO

SiO 2

Al 2 o 3

content

0.6459

5.6

3.1

0.2

6.0

0.026

0.073

0.16

66.97

12.31

[0035] The recovery method of copper ore includes the following steps:

[0036] A: Low-alkalinity copper roughing: add lime f1500g / ton to the raw ore for grinding, and add citric acid: sodium sulfite: pyrogallic acid = 1.1:0.9:0.5 to the slurry that is ground to -0.074mm and accounts for 61%. The prepared combined inhibitor a450 g / ton, butylamine black drug b30 g / ton and 2# oil c4 g / ton are used for roughing, and copper rough concentrate is obtained at one time; adding butylamine black drug b12 g / ton for copper Rough separation 2 to obtain secondary copper rough concentrate.

[0037] B: Copper beneficiation: add 150 g / ton of the above combination inhibitor and 80 g / ton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com