Preparation method for nanoscale dispersive high-performance organic/inorganic hybrid membrane

A nano-scale, high-performance technology, applied in the field of membrane separation, can solve the problems of shortening the film-forming process, environmental pollution, poor performance of the separation membrane, and practical application limitations, so as to shorten the preparation time, avoid toxic and harmful solvents, and improve the preparation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

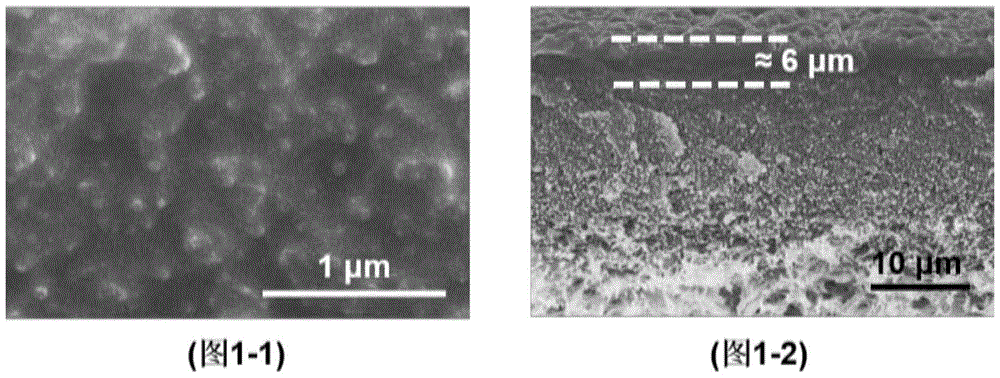

[0072] The porous base membrane is polysulfone (PSf) flat ultrafiltration membrane, the molecular weight cut-off is 20,000, the liquid oligomer is vinyl-terminated PDMS (viscosity is 300mPa s), and the cross-linking agent and catalyst are respectively PMHS. and chloroplatinic acid, the selected inorganic nanoparticles are ZIF-8, the environmentally friendly solvent is ethanol, and the selected high-temperature baking lamps are Yuba heating lamps.

[0073] Preparation method and steps:

[0074] 1) The liquid vinyl-terminated PDMS is directly placed in a container for use; PMHS and chloroplatinic acid are mixed and dissolved in a small amount of ethanol solvent, so that the mass concentrations of PMHS and chloroplatinic acid are 10% and 0.1% respectively , then add ZIF-8 nanoparticles so that the content is 10% of the PMHS mass, mix well and set aside;

[0075] 2) Cut the pretreated PSf base film into a disc with a diameter of 20 cm, fix it on a vertically placed film stage, an...

Embodiment 2

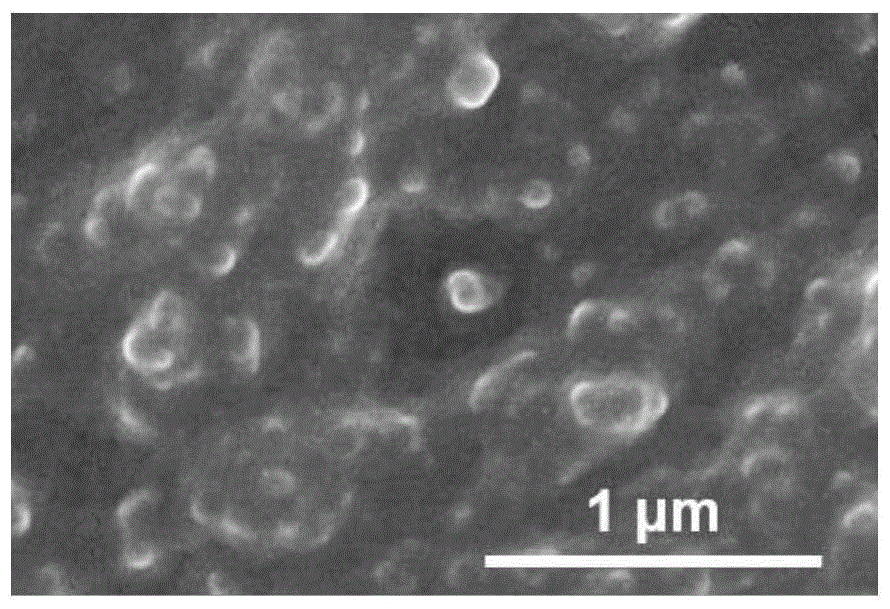

[0082] The porous base membrane is polysulfone (PSf) flat ultrafiltration membrane, the molecular weight cut-off is 20,000, the liquid oligomer is vinyl-terminated PDMS (viscosity is 300mPa s), and the cross-linking agent and catalyst are respectively PMHS. and chloroplatinic acid, the selected inorganic nanoparticles are ZIF-8, the environmentally friendly solvent is ethanol, and the selected high-temperature baking lamps are Yuba heating lamps.

[0083] Preparation method and steps:

[0084] 1) The liquid vinyl-terminated PDMS is directly placed in a container for use; PMHS and chloroplatinic acid are mixed and dissolved in a small amount of ethanol solvent, so that the mass concentrations of PMHS and chloroplatinic acid are 10% and 0.1% respectively , then add ZIF-8 nanoparticles to make its content 2.5% of the PMHS mass, mix well and set aside;

[0085] 2) Cut the pretreated PSf base film into a disc with a diameter of 20 cm, fix it on a vertically placed film stage, and ...

Embodiment 3

[0092] The porous base membrane is polysulfone (PSf) flat ultrafiltration membrane, the molecular weight cut-off is 20,000, the liquid oligomer is vinyl-terminated PDMS (viscosity is 300mPa s), and the cross-linking agent and catalyst are respectively PMHS. and chloroplatinic acid, the selected inorganic nanoparticles are ZIF-8, the environmentally friendly solvent is ethanol, and the selected high-temperature baking lamps are Yuba heating lamps.

[0093] Preparation method and steps:

[0094] 1) The liquid vinyl-terminated PDMS is directly placed in a container for use; PMHS and chloroplatinic acid are mixed and dissolved in a small amount of ethanol solvent, so that the mass concentrations of PMHS and chloroplatinic acid are 10% and 0.1% respectively , then add ZIF-8 nanoparticles to make its content 15% of the PMHS mass, mix well and set aside;

[0095] 2) Cut the pretreated PSf base film into a disc with a diameter of 20 cm, fix it on a vertically placed film stage, and rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com