Modified diaphragm and preparation method and application therefor

A diaphragm and modification technology, which is applied in the field of double-sided modified modified diaphragm and its preparation, can solve the problems of cycle life and rate performance of modified diaphragm lithium-sulfur batteries, weak alumina adsorption capacity, pierced diaphragm, etc. problem, to achieve the effect of inhibiting the shuttling effect, inhibiting the growth, and preventing the puncture of the septum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

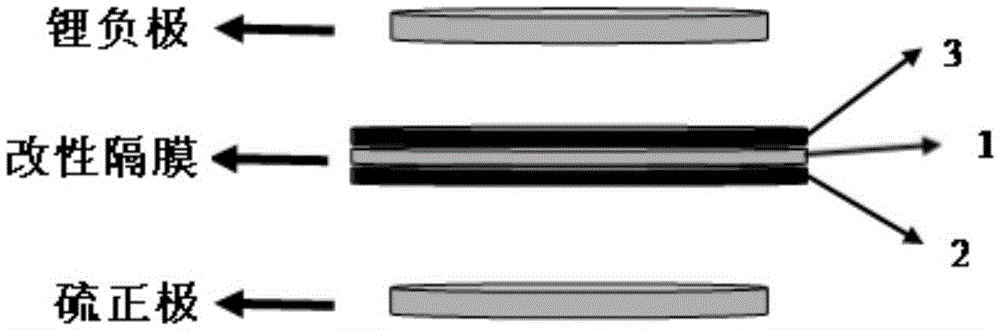

[0039] A modified diaphragm of the present invention includes a Celgard2325 diaphragm matrix (polypropylene / polyethylene / polypropylene three-layer diaphragm) and an electronic conductive coating (graphene and carbon nanotube mixed coating) on both surfaces of the Celgard2325 diaphragm, and Inorganic hard coating (carbon nitride coating); the mass content of graphene in the electronic conductive coating is 50%; the thickness of the electronic conductive coating is 50 μm; the thickness of the inorganic hard coating is 50 μm.

[0040] The preparation method of the modified diaphragm of this embodiment includes the following steps:

[0041] (1) Take a Celgard2325 diaphragm, clean it with ethanol, and dry it for later use;

[0042] (2) Disperse 0.9mg carbon nitride powder and 0.1mg polyvinylidene fluoride (PVDF) in N-methylpyrrolidone (NMP) to prepare a uniform inorganic hard material slurry;

[0043] Disperse 0.5mg graphene, 0.4mg carbon nanotubes and 0.1mg polyvinylidene fluoride (PVDF...

Embodiment 2

[0050] A modified diaphragm of the present invention, comprising a polyethylene diaphragm and an electronic conductive coating (graphene and carbon nanofiber mixed coating) and an inorganic hard coating (boron carbide coating) on both surfaces of the polyethylene diaphragm; The mass content of graphene in the electronic conductive coating is 40%; the thickness of the electronic conductive coating is 10 μm; the thickness of the inorganic hard coating is 10 μm.

[0051] The preparation method of the modified diaphragm of this embodiment includes the following steps:

[0052] (1) Take a polyethylene diaphragm, clean it with ethanol, and dry it for later use;

[0053] (2) Disperse 0.9 mg of boron carbide powder and 0.1 mg of polyvinylidene fluoride (PVDF) in N-methylpyrrolidone (NMP) to prepare a uniform inorganic hard material slurry;

[0054] Disperse 0.4mg graphene, 0.5mg carbon nanofibers and 0.1mg polyvinylidene fluoride (PVDF) in N-methylpyrrolidone (NMP) to prepare a uniform elec...

Embodiment 3

[0058] A modified diaphragm of the present invention includes a polypropylene diaphragm substrate and an electronic conductive coating (graphene and porous carbon mixed coating) and an inorganic hard coating (silicon nitride coating) on both surfaces of the polypropylene diaphragm. The mass content of graphene in the electronic conductive coating is 20%; the thickness of the electronic conductive coating is 50 μm; the thickness of the inorganic hard coating is 50 μm.

[0059] The preparation method of the modified diaphragm of this embodiment includes the following steps:

[0060] (1) Take a polypropylene diaphragm, clean it with ethanol, and dry it for later use;

[0061] (2) Disperse 0.8 mg of silicon nitride powder and 0.2 mg of polytetrafluoroethylene (PTFE) in water to prepare a uniform inorganic hard material slurry;

[0062] Disperse 0.2mg graphene, 0.6mg porous carbon and 0.2mg polyvinylidene fluoride (PVDF) in N-methylpyrrolidone (NMP) to prepare a uniform electronic conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com