Wood plastic clothes rack and preparation technology thereof

A hanger and wood-plastic technology, which is applied in the field of wood-plastic hangers and its preparation technology, can solve the problems of high difficulty, easy peeling of electroplating, and easy aging, etc., to improve hardness and flexural modulus, superior mechanical properties, and improve aging resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

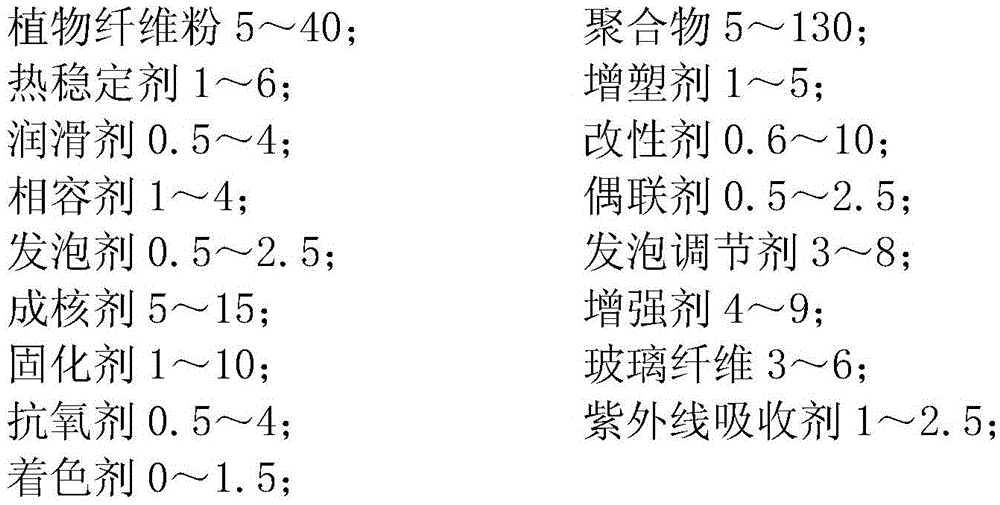

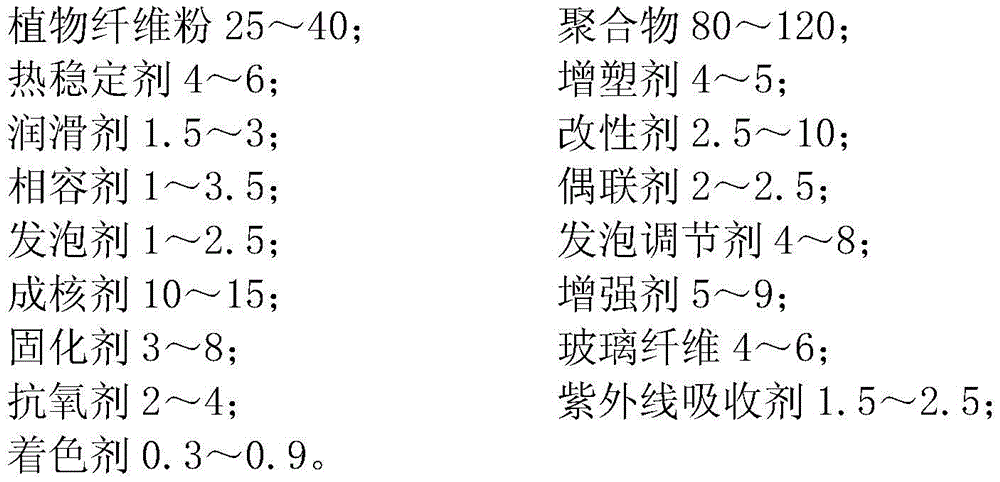

Method used

Image

Examples

Embodiment 1

[0041]1) Weigh each component according to the formula of Example 1 in the following Table 1, place it in a high-speed and low-speed mixer for mixing evenly (mixing time is about 8 minutes), and discharge when the temperature of the material drops to 40°C; discharge The material is sent to the granulator for granulation (the temperature of the granulator is controlled at 135-150°C) to obtain pellets;

[0042] 2) The obtained granules are fed into the injection molding machine to obtain the wood-plastic hanger billet through injection molding, wherein the process parameters during injection molding are: the temperature of the barrel is controlled at 150-190°C (the temperature in the first zone of the barrel is set to 150°C, the material The temperature of barrel 2 zone is set to 165°C, the temperature of barrel 3 zone is set to 180°C, the temperature of barrel 4 zone is set to 190°C, the temperature of barrel 5 zone is set to 190°C, the nozzle temperature is 200°C), and the inje...

Embodiment 2

[0047] 1) Weigh each component according to the formula of Example 2 in the following Table 1, put it in a high-speed and low-speed mixer for mixing evenly (mixing time is about 10 minutes), and discharge when the temperature of the material drops to 45°C; discharge The material is sent to the granulator for granulation (the temperature of the granulator is controlled at 150-180°C) to obtain pellets;

[0048] 2) The obtained granules are fed into an injection molding machine to obtain a wood-plastic hanger blank through injection molding. The process parameters during injection molding are as follows: the temperature of the barrel is controlled at 170-220°C (the temperature in the first zone of the barrel is set at 170°C, and the temperature of the barrel is set at 170°C. The temperature of barrel 2 zone is set to 180°C, the temperature of barrel 3 zone is set to 185°C, the temperature of barrel 4 zone is set to 190°C, the temperature of barrel 5 zone is set to 200°C, the nozzl...

Embodiment 3

[0053] 1) Weigh each component according to the formula of Example 3 in the following Table 1, place it in a high-speed and low-speed mixer for mixing evenly (mixing time is about 9 minutes), and discharge when the temperature of the material drops to 42°C; discharge The material is sent to the granulator for granulation (the temperature of the granulator is controlled at 150-190°C) to obtain pellets;

[0054] 2) The obtained granules are fed into an injection molding machine to obtain a wood-plastic hanger blank through injection molding. The process parameters during injection molding are as follows: the temperature of the barrel is controlled at 170-220°C (the temperature in the first zone of the barrel is set at 170°C, and the temperature of the barrel is set at 170°C. The temperature of barrel 2 zone is set to 190°C, the temperature of barrel 3 zone is set to 200°C, the temperature of barrel 4 zone is set to 210°C, the temperature of barrel 5 zone is set to 220°C, the nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com