Preparation method of graphene oxide/boric acid-based metal organic framework/polyurethane material

An organic framework and graphene technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, organic chemistry, etc., can solve problems such as poor selectivity, secondary environmental pollution, cumbersome operation, etc., and achieve good mechanical properties , the effect of efficient specific recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of graphene oxide (GO):

[0040] Add 2g of graphite powder and 0.2g of sodium nitrate into 50mL of concentrated sulfuric acid, cool to below 5°C; add 1g of potassium permanganate into the above reaction system, and stir at 30°C for 2 hours; then, slowly add 100mL of distilled water Add to the flask until the temperature reaches 98°C. Finally, 10 mL of hydrogen peroxide (30%) was added into the reaction system to react for 15 min. Afterwards, 100ml of concentrated hydrochloric acid (5%) was added to the mixture at room temperature and washed with distilled water several times, and finally dried at 60°C.

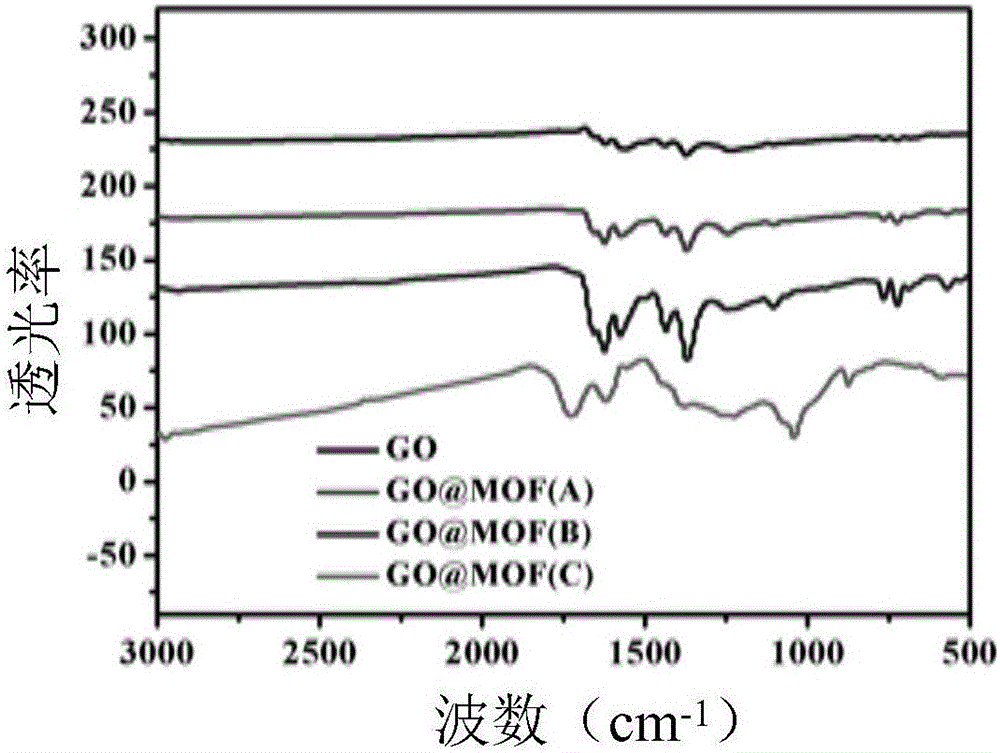

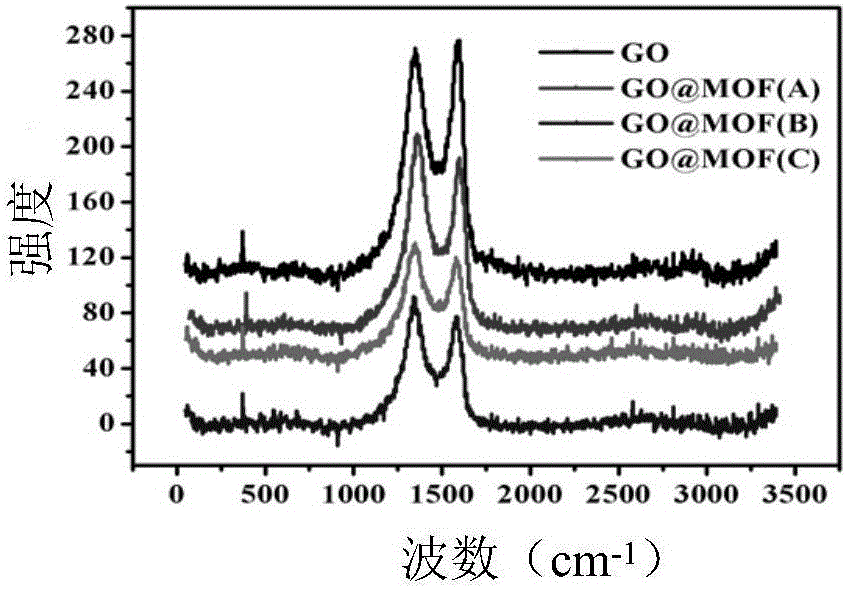

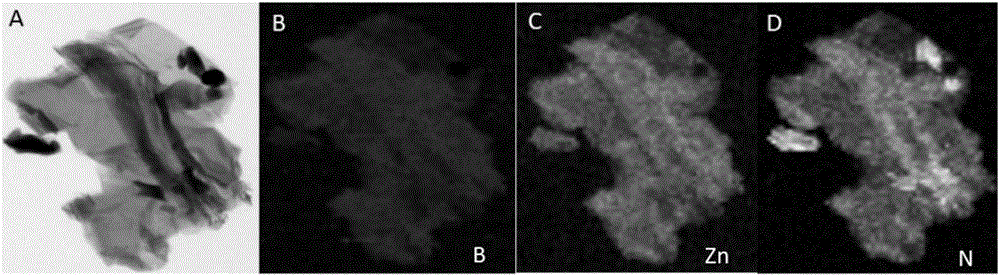

[0041] (2) Preparation of boric acid-based metal-organic framework (GOMOF(C)) grown in situ on graphene oxide:

[0042] First, 40 mg of graphene oxide, 5 mg of 3,5-dicarboxyphenylboronic acid, 5 mg of 1,3,5-benzenetricarboxylic acid, 200 mg of zinc nitrate hexahydrate, 5 mL of N,N-dimethyl Formamide was added into a 50mL reactor and ultrasonically dis...

Embodiment 2

[0056] (1) Preparation of graphene oxide (GO):

[0057] First, add 5g of graphite powder and 1g of sodium nitrate into 100mL of concentrated sulfuric acid and cool to below 5°C. Next, 5 g of potassium permanganate was added into the reaction system, and stirred at 30° C. for 2 hours. Subsequently, 150 mL of distilled water was slowly added to the flask until the temperature reached 98°C. Finally, 50 mL of hydrogen peroxide (30%) was added into the reaction system to react for 15 min. Afterwards, 400 mL of concentrated hydrochloric acid (5%) was added to the mixture at room temperature and washed with distilled water several times, and finally dried at 60°C.

[0058] (2) Preparation of boric acid-based metal-organic framework (GOMOF(C)) grown in situ on graphene oxide:

[0059] First, 50 mg of graphene oxide, 10 mg of 3,5-dicarboxyphenylboronic acid, 10 mg of 1,3,5-benzenetricarboxylic acid, 400 mg of zinc nitrate hexahydrate, 20 mL of N,N-dimethyl Formamide was added into ...

Embodiment 3

[0066] (1) Preparation of graphene oxide (GO):

[0067] First, add 3g of graphite powder and 0.5g of sodium nitrate into 69mL of concentrated sulfuric acid, and cool to below 5°C. Next, 3g of potassium permanganate was added to the reaction system, and stirred at 30°C for 2 hours; then, 138mL of distilled water was slowly added into the flask until the temperature reached 98°C. Finally, 30mL hydrogen peroxide (30%) was added to the reaction system for 15min. After that, 200mL of concentrated hydrochloric acid (5%) was added to the mixture at room temperature and washed with distilled water several times, and finally dried at 60°C.

[0068] (2) Preparation of boric acid-based metal-organic framework (GOMOF(C)) grown in situ on graphene oxide:

[0069]First, 45 mg of graphene oxide, 7.8 mg of 3,5-dicarboxyphenylboronic acid, 7.8 mg of 1,3,5-benzenetricarboxylic acid, 300 mg of zinc nitrate hexahydrate, 10 mL of N,N-dimethyl Phenyl formamide was added into a 50mL reactor and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com