High-density molybdenum-niobium alloy target and preparation process thereof

A molybdenum-niobium alloy and preparation process technology, applied in metal material coating process, ion implantation coating, coating and other directions, can solve the problems of high equipment condition requirements, complex process, reduced coating efficiency, etc., to ensure coating quality, Overcome the effect of coarse tissue and avoid particle splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

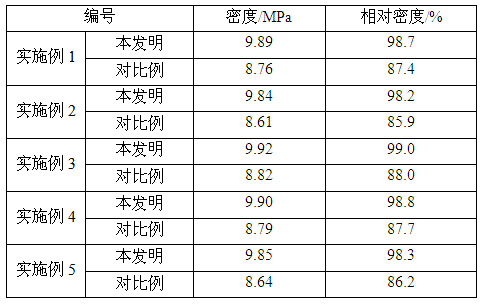

Examples

Embodiment 1

[0024] A high-density molybdenum-niobium alloy target is composed of the following components measured by weight percentage: 9.97% of niobium powder, 0.3% of zirconium hydride, and the balance of molybdenum powder.

[0025] Among them, molybdenum powder, niobium powder and zirconium hydride (ZrH 2 ) are common commercially available products, and the molybdenum powder is selected from Dengfeng Tungsten and Molybdenum Materials Factory with the brand name FMo-1. is 800ppm; the niobium powder is selected from the product of Zhuzhou Cemented Carbide Group Co., Ltd. brand FNb-1, the Fischer particle size of the niobium powder is 8μm, the carbon content of the niobium powder is 130ppm, and the oxygen content of the niobium powder is 1500ppm; ZrH 2 Products selected from Shanghai Shuitian Material Technology Co., Ltd., chemically pure, with a Fisher particle size of 2 μm.

[0026] The preparation process of the above-mentioned high-density molybdenum-niobium alloy target includes t...

Embodiment 2

[0034] A high-density molybdenum-niobium alloy target is composed of the following components measured by weight percentage: 9.96% niobium powder, 0.4% zirconium hydride, and the balance is molybdenum powder.

[0035] Among them, molybdenum powder, niobium powder and zirconium hydride (ZrH 2 ) are common commercially available products. The molybdenum powder is selected from Luoyang Yongzhuo Tungsten and Molybdenum Materials Co., Ltd. with the brand name FMo-1. The content is 1200ppm; the niobium powder is selected from the product of Dongfang Tantalum Industry Co., Ltd. with the brand name FNb-1, the Fischer particle size of the niobium powder is 10μm, the carbon content of the niobium powder is 500ppm, and the oxygen content of the niobium powder is 2000ppm; ZrH 2 Products selected from Jinzhou Haotian Titanium Powder Processing Co., Ltd., chemically pure, with a Fischer particle size of 3.0 μm.

[0036] The preparation process of the above-mentioned high-density molybdenum...

Embodiment 3

[0044] A high-density molybdenum-niobium alloy target is composed of the following components measured by weight percentage: 5.982% of niobium powder, 0.3% of zirconium hydride, and the balance of molybdenum powder.

[0045] Among them, molybdenum powder, niobium powder and zirconium hydride (ZrH 2 ) are common commercially available products, and the molybdenum powder is selected from Dengfeng Tungsten and Molybdenum Materials Factory with the brand name FMo-1. The niobium powder is selected as FNb-1 from Zhuzhou Cemented Carbide Group Co., Ltd., the Fischer particle size of the niobium powder is 8 μm, the carbon content of the niobium powder is 130 ppm, and the oxygen content of the niobium powder is 1500 ppm; ZrH 2 The product of Shanghai Shuitian Material Technology Co., Ltd. is selected, which is chemically pure and has a Fischer particle size of 2 μm.

[0046] The preparation process of the above-mentioned high-density molybdenum-niobium alloy target includes the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com