A kind of preparation method of conductive photonic crystal hydrogel

A technology of photonic crystals and hydrogels, which is applied in the field of preparation of responsive photonic crystal materials, can solve problems such as lack of electrical conductivity, and achieve the effect of simple method and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

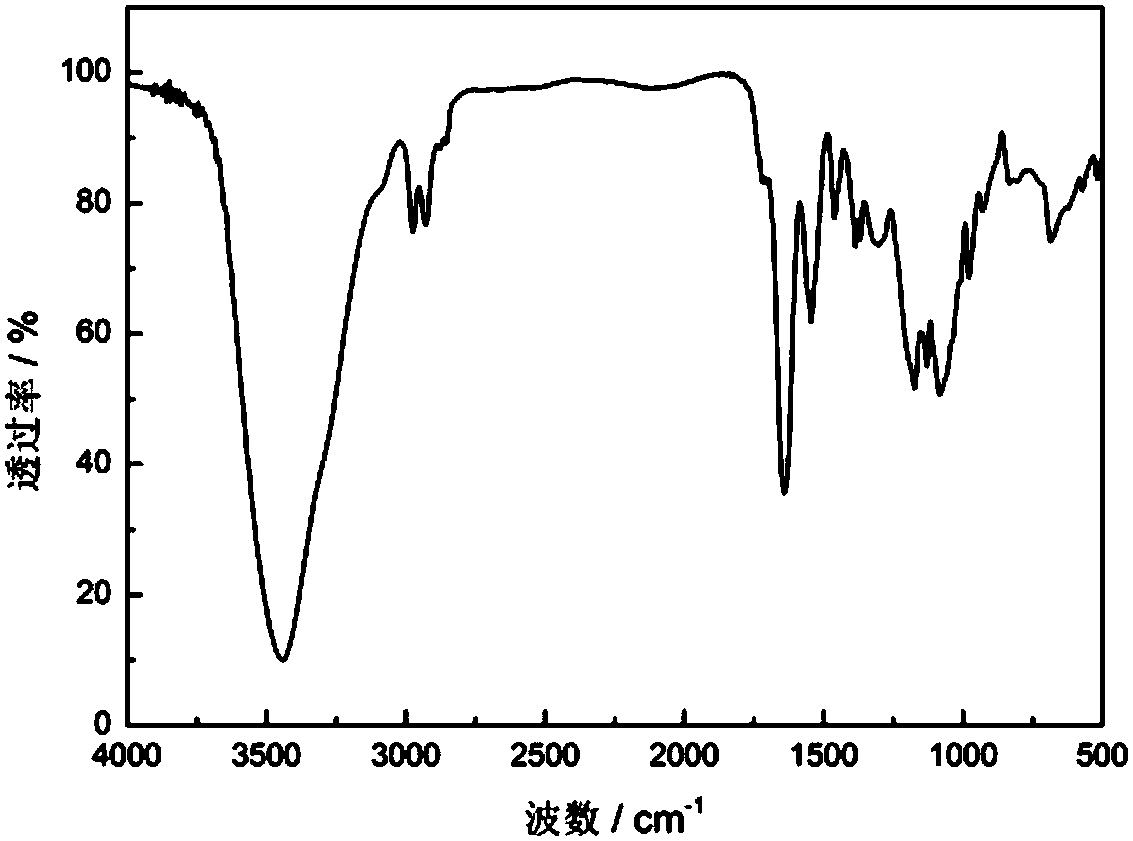

[0030] At room temperature, weigh 1.0g of N-isopropylacrylamide, 0.01g of N-N-methylenebisacrylamide, and 0.2g of acrylic acid, place them in a beaker, and add 120mL of ultrapure water. Magnetic stirring was performed at a stirring speed of 300 rpm for 30 minutes to fully dissolve the reactant and transfer it to a 250 mL three-neck flask. Place the three-necked flask in an oil bath, heat it to 80°C under the protection of argon atmosphere with stirring, condensing and refluxing, and pass in argon for 25 minutes to achieve the purpose of removing dissolved oxygen in ultrapure water. Next, 12 mL of potassium persulfate solution with a mass fraction of 5% was added into the three-necked flask, and reacted at 80° C. for 4 h. After the reaction was completed, the colloidal microsphere emulsion was cooled to room temperature under the protection of an argon atmosphere. Then, the colloidal emulsion was centrifuged at 27° C. at a rotational speed of 11000 rpm to obtain PNIPAM-Co-AAc ...

Embodiment 2

[0033]At room temperature, weigh 1.5g of N-isopropylacrylamide, 0.02g of N-N-methylenebisacrylamide, and 0.3g of acrylic acid, place them in a beaker, and add 140mL of ultrapure water. Magnetic stirring was performed at a stirring speed of 300 rpm for 30 minutes to fully dissolve the reactant and transfer it to a 250 mL three-neck flask. Place the three-neck flask in an oil bath, heat it to 70°C under the protection of argon atmosphere under stirring, condensing and refluxing, and pass in argon for 35 minutes to achieve the purpose of removing dissolved oxygen in ultrapure water. Next, 10 mL of potassium persulfate solution with a mass fraction of 8% was added into the three-necked flask, and reacted at 70° C. for 4 h. After the reaction was completed, the colloidal microsphere emulsion was cooled to room temperature under the protection of an argon atmosphere. Then, the colloidal emulsion was centrifuged at 30° C. at 10,000 rpm to obtain PNIPAM-Co-AAc colloidal microspheres....

Embodiment 3

[0035] At room temperature, weigh 2.5g of N-isopropylacrylamide, 0.03g of N-N-methylenebisacrylamide, and 0.4g of acrylic acid, put them in a beaker, and add 160mL of ultrapure water. Magnetic stirring was performed at a stirring speed of 300 rpm for 30 minutes to fully dissolve the reactant and transfer it to a 250 mL three-neck flask. Place the three-necked flask in an oil bath, heat to 60°C under stirring, condensing and refluxing, and protect by argon atmosphere, and let argon flow in for 40 minutes to achieve the purpose of removing dissolved oxygen in ultrapure water. Next, 9 mL of potassium persulfate solution with a mass fraction of 10% was added into the three-necked flask, and reacted at 60° C. for 6 h. After the reaction was completed, the colloidal microsphere emulsion was cooled to room temperature under the protection of an argon atmosphere. Then, the colloidal emulsion was centrifuged at 33° C. at 8000 rpm to obtain PNIPAM-Co-AAc colloidal microspheres, which w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com