The preparation method of ethyl isopentyl malonate diethyl ester

A technology of diethyl ethyl isopentyl malonate and diethyl ethyl malonate, which can be used in the preparation of carboxylic acid esters, organic compounds, metal alcohols, etc., and can solve the problem of low yield and purity etc. to achieve the effect of high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

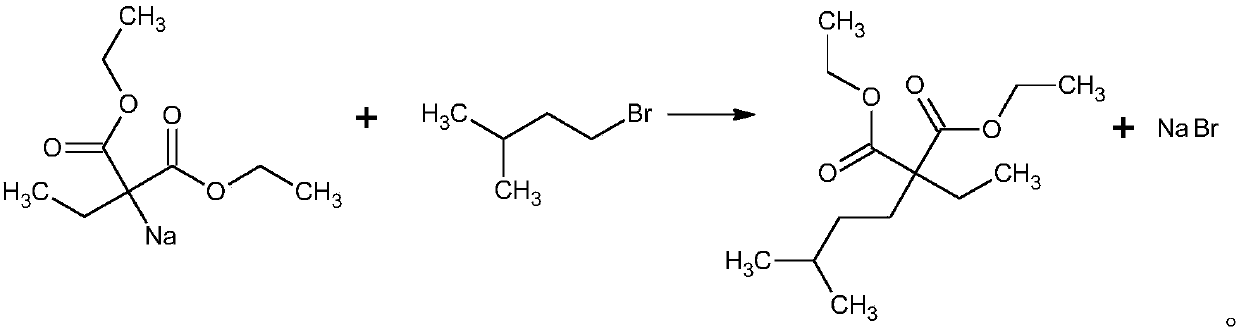

[0015] A preparation method of diethyl ethyl isopentyl malonate, comprising the following steps:

[0016] 1) Ethanol and sodium react to generate sodium ethylate

[0017] 2) adding diethyl ethylmalonate to the sodium ethylate obtained in step 1), generating diethyl ethylmalonate sodium salt;

[0018] 3) Add bromoisopentane to the diethyl ethylmalonate sodium salt obtained in step 2), and react to generate diethyl ethylmalonate.

[0019] The invention uses ethanol, sodium, diethyl ethylmalonate and bromoisopentane as raw materials to prepare diethyl ethylisoamylmalonate with high yield and high purity, and meets the quality standard of medicines.

[0020] Wherein, the reaction of ethanol and sodium generates the reaction formula of sodium ethylate as follows:

[0021] Na+C 2 h 5 OH→C 2 h 5 ONa+H 2 ↑.

[0022] In the embodiment of the present invention, the preparation of sodium ethylate is in N 2 Prepared under atmosphere, avoiding the problem of easy decomposition and...

Embodiment 1

[0034] Feed N into the reactor containing 1200g ethanol 2 , add 80g of sodium to absolute ethanol, at 72°C, after 12h of reaction, stop feeding N 2 ; At the same time, heat the temperature to 80°C to remove ethanol to obtain sodium ethylate; then pass cooling water into the cooling water jacket of the reactor for 30 minutes, and then pass into N 2 , and slowly add 600g diethyl ethyl malonate dropwise to sodium ethylate, stop feeding cooling water and N 2 , to obtain diethyl ethyl malonate sodium salt; 450g of bromoisopentane was added dropwise, and kept at 76°C for 30min, filtered and rectified to obtain diethyl ethyl malonate.

[0035] The yield of diethyl ethyl isopentyl malonate prepared in this example was 83.33%, and the purity was 99.52%.

Embodiment 2

[0037] Feed N into the reactor containing 1350g ethanol 2 , add 82g of sodium to absolute ethanol, at 73°C, after reacting for 13h, stop feeding N 2 At the same time, heat the temperature to 80°C to remove ethanol to obtain sodium ethylate; then pass cooling water into the cooling water jacket of the reactor for 60 minutes, and then pass into N 2 , and slowly add 600g diethyl ethyl malonate dropwise to sodium ethylate, stop feeding cooling water and N 2 , to obtain diethyl ethyl malonate sodium salt; 460g of bromoisopentane was added dropwise, and kept at 80°C for 45min, filtered and rectified to obtain diethyl ethyl isopentyl malonate.

[0038] The yield of diethyl ethyl isopentyl malonate prepared in this example was 82.95%, and the purity was 99.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com