Environment-friendly type long-life fettling sand and production method thereof

An environment-friendly, long-life technology, applied in the field of refractory materials for converter protection in iron and steel smelting, can solve the problems of unsatisfactory thermal shock resistance and oxidation resistance of refractory materials, high manual labor intensity, and affecting the overall furnace life, etc., to achieve Outstanding environmental protection effect, short sintering time, and uniform skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

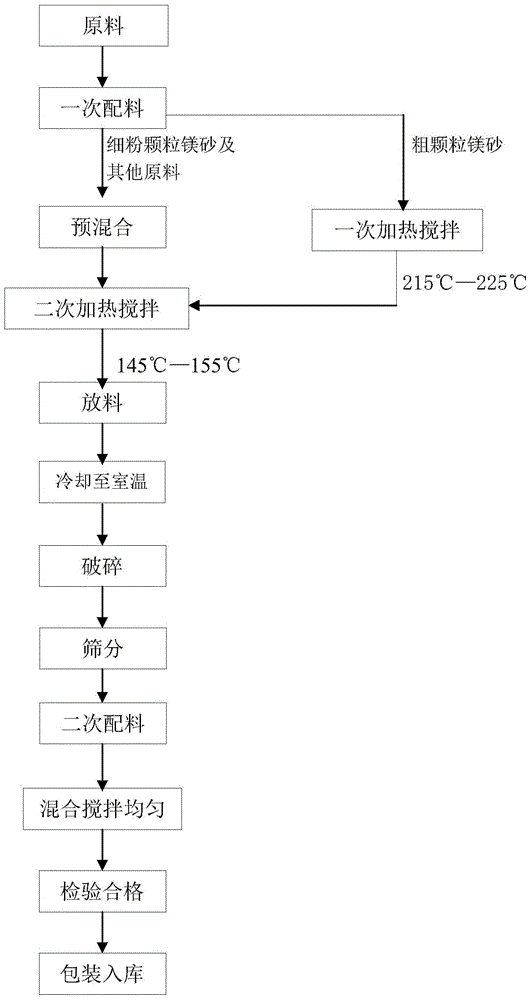

Method used

Image

Examples

Embodiment 1

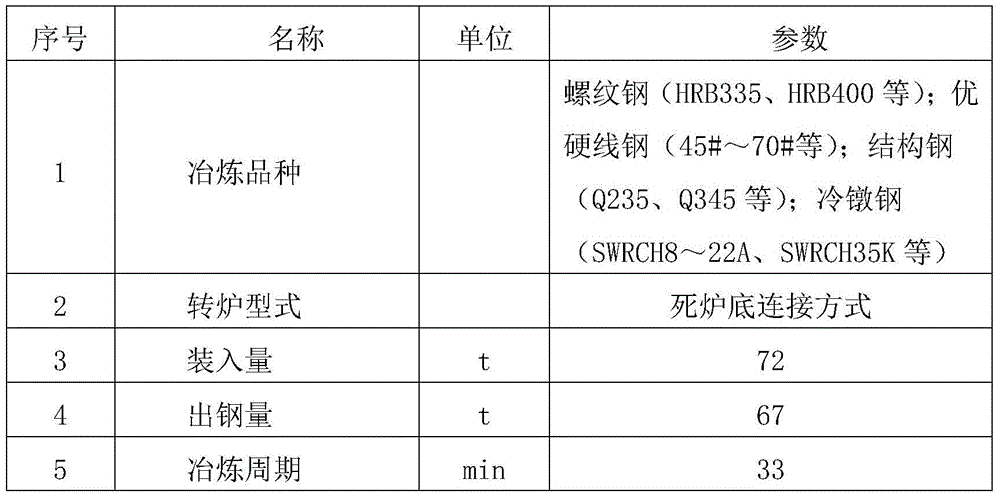

[0054] Take the repairing sand for a 70-ton converter in a steel plant as an example. The conditions are shown in Table 2:

[0055] Table 2 Production conditions of a 70-ton converter in a steel plant

[0056]

[0057]

[0058] In order to achieve the above purpose, the furnace sand for the converter can be realized through the following technical solutions:

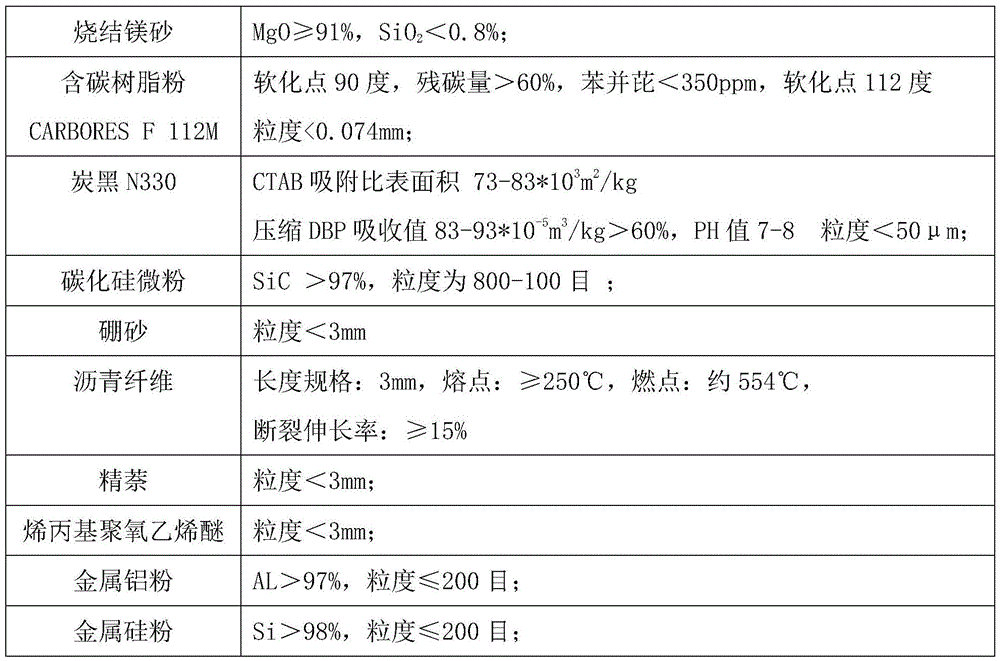

[0059] The 70-ton converter sand is an environmentally friendly and long-life repairing sand, which is prepared from the following raw materials in parts by weight: MS91 dead-burned magnesia: 65 parts, CARBORESF112M carbon-containing resin powder and superfine carbon black N330. Composite carbon source : 12 parts, asphalt fiber: 0.01 parts, composite fluidizing agent composed of refined naphthalene and allyl polyoxyethylene ether: 2.5 parts, composite sintering agent composed of silicon carbide micropowder and borax: 0.2 parts, metal aluminum powder and metal silicon Compound antioxidant composed of powder: 2.0 p...

Embodiment 2

[0071] Take the furnace sand for 300 tons converter in a steel plant as an example. The conditions are shown in Table 3:

[0072] Table 3 Production conditions of a 300-ton converter in a steel plant

[0073] 1 Nominal capacity 210t 2 Furnace ratio 1.0m 3 / t. 3 Average tapping amount 215t 4 Maximum tapping amount 230t 5 Average smelting cycle 45min, of which pure oxygen blowing time: 15min 6 blowing mode top and bottom blow 7 Tapping temperature 1630~1690℃ 8 Final slag alkalinity 2.8~4.0 9 furnace age 10000 furnaces 10 Tapping time 4.5~8min

[0074] In order to achieve the above purpose, the furnace sand for the converter can be realized through the following technical solutions:

[0075] The 300-ton converter sand is an environmentally friendly and long-life repairing sand, which is prepared from the following raw materials in parts by weight: MS95 mid-grade magnesia sintered magnesia: 90 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com