Sintering bearing plate and sintering method of planar ceramic target material

A ceramic target material and sintering method technology, which is applied in the field of ceramic target material sintering, can solve problems such as reducing friction, and achieve the effects of reducing friction, promoting full sintering, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for sintering a planar ceramic target, the steps are as follows:

[0033] 1) ZnO / Al 2 o 3 The AZO granulated powder with a composition ratio of 98:2wt% was successively strengthened by steel mold dry pressing and cold isostatic pressing to obtain a green body with a density greater than 56%, with a size of W400×L800×H15mm;

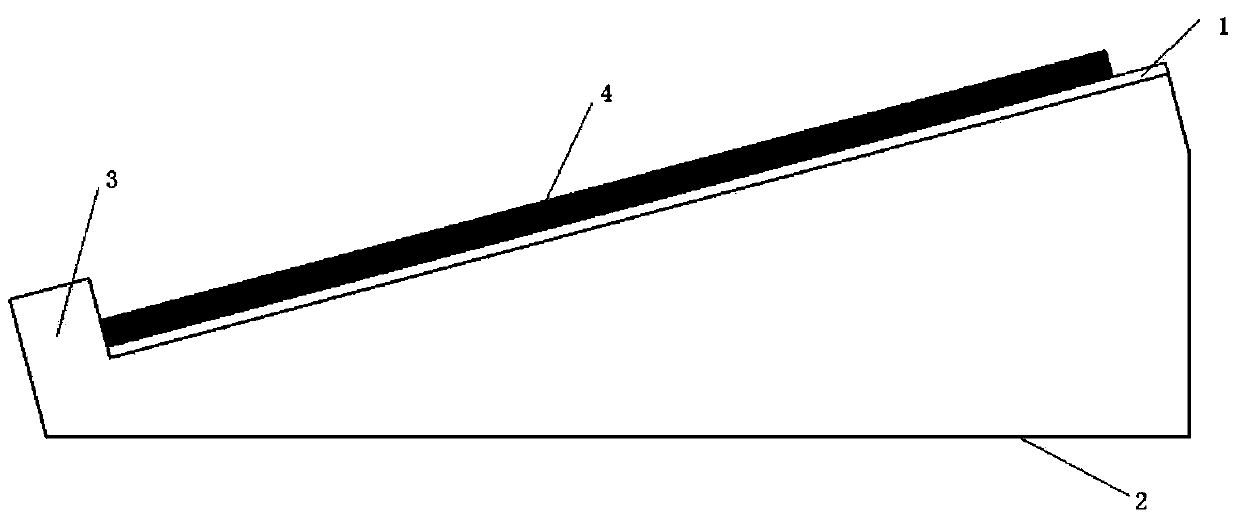

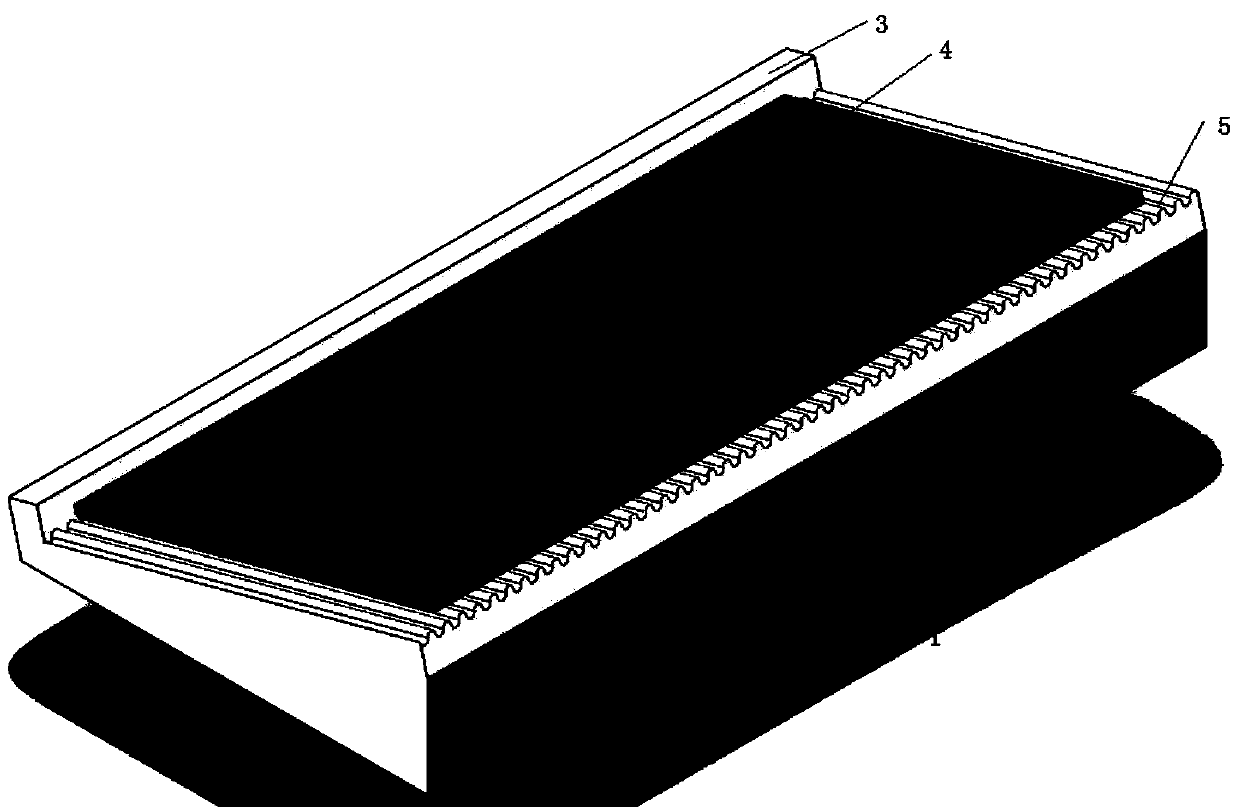

[0034] 2) if Figure 1-4 As shown, the alumina setter of this embodiment includes a support surface 1 and a horizontal surface 2, the support surface 1 is an inclined surface with an inclined angle to the horizontal surface 2, and the inclination angle of the support surface 1 relative to the horizontal surface 2 is 10°, and the support surface The bottom edge of the bottom edge is provided with a baffle plate 3, and the baffle plate 3 is perpendicular to the support surface 1; the support surface 1 is provided with several evenly spaced and parallel strip corrugated protrusions 5, and the strip corrugated protrusions 5 The cross section...

Embodiment 2

[0037] A method for sintering a planar ceramic target, the steps of which are basically the same as in Example 1, except that in this example, the inclination angle of the support surface of the setter relative to the horizontal plane is 15°.

Embodiment 3

[0039] A method for sintering a planar ceramic target, the steps of which are basically the same as in Example 1, except that in this example, the inclination angle of the support surface of the setter plate relative to the horizontal plane is 20°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com