Micro-electrolysis system and its preparation method and application

A micro-electrolysis and system technology, applied in the interdisciplinary field of bio-nano technology, can solve the problems of sewage treatment needs to be improved, narrow scope of application, high cost of removal, etc., and achieve the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

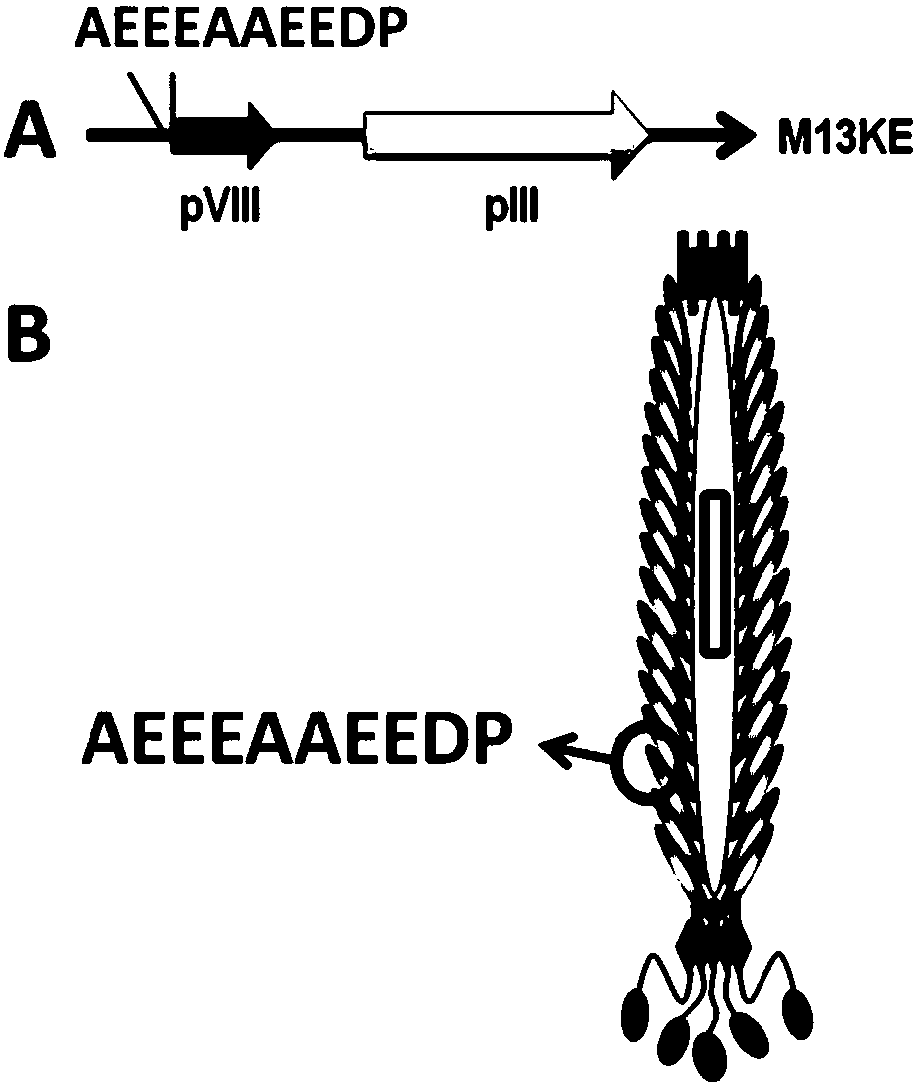

[0053] Example 1: Genetic engineering of the p8 capsid protein around the M13 bacteriophage

[0054] The N-terminal sequence of 2700 copies of p8(pVIII) protein in the wild-type M13 phage (purchased from NEB) is N-Ala-Glu-Gly-Asp-Asp-Pro-...(N-AEGDDP-). In this example, the strongly negatively charged polypeptide sequence AEEEAAEEDP was designed, and its gene sequence GAAGAAGAAGCGGCGGAAGAG (SEQ ID NO: 6) was inserted into the N-terminus of the wild-type M13 phage to obtain a gene with strong adsorption to multiple metal ions at the same time Engineering phage M13-6ED. The specific operation method is as follows:

[0055] First, the M13KE phage vector (Mao et al. Virus-Based Toolkit for the DirectedSynthesis of Magnetic and Semiconductor Nanowires. Science. 2004, 303: 213-217) was digested with Pst I (15U / μl, purchased from TaKaRa Biotechnology, Dalian) , the reaction system is: Pst I, 1 μl; 10×H buffer, 2 μl; M13KE phage carrier, 1 μg; add sterile water to a total volume of ...

Embodiment 2

[0058] Example 2: Construction of Fe-Ni@M13 micro-electrolysis system

[0059] Using the method described in Example 1, the recombinant M13 phage M13-6ED obtained in Example 1 was amplified. Take an appropriate amount of recombinant M13 phage obtained by amplification, and supplement the volume to 200 μL with TBS buffer (50 mM Tris-HCl, 150 mM NaCl, pH=7.5). In the obtained mixture, the titer of the recombinant M13 phage is 10 11 pfu, and then add an equal volume (100 μL each) mixed ferrous chloride (2mM) and nickel chloride (2mM) solution to it, to treat the recombinant M13 phage on Fe 2+ and Ni 2+ After the adsorption is complete (stand still for about 5-10min), add the reducing agent NaBH 4 Solution (4mM) to the Fe in the system 2+ and Ni 2+ Perform reduction (reaction while oscillating), and react at normal temperature and pressure for about 10 minutes to construct the Fe-Ni@engineeredM13-1 micro-electrolysis system. The nano-iron and nano-nickel particles uniformly di...

Embodiment 3

[0060] Example 3: Fe-Ni@engineered M13-1 micro-electrolysis system efficiently reduces p-chloronitrobenzene and hexavalent chromium ions

[0061]In this example, the Fe-Ni@engineeredM13-1 micro-electrolysis system constructed in Example 2 was used for the reduction of p-chloronitrobenzene. Take 200 μL of p-chloronitrobenzene solution with a concentration of 1 mg / L, add 20 μL of phosphoric acid (2mol / L) to acidify the p-chloronitrobenzene solution, and then add the Fe-Ni@engineeredM13-1 micro-electrolysis system obtained in Example 2 to carry out Reduction reaction about 10min. The Fe@engineered M13-1 system (the preparation method is the same as in Example 2, the difference being that no nickel chloride solution was added), nano-iron particles, and a reducing agent were used as a control. Use high-performance liquid chromatography (chromatographic column: Gemini 5u C18110A (250 * 4.6mm); Mobile phase methanol: water=75:25, flow rate 1ml / min, carry out vacuum suction filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com