Resin CBN grinding disc for grinding copper alloy

A grinding disc and copper alloy technology, which is applied in the field of grinding wheel manufacturing, can solve the problems of unknowable product formula, easy blockage of grinding wheel by grinding debris, high roughness value, etc., and achieve the effect of not easily deformed, low roughness value and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] 1. Prepare the matrix according to the general method;

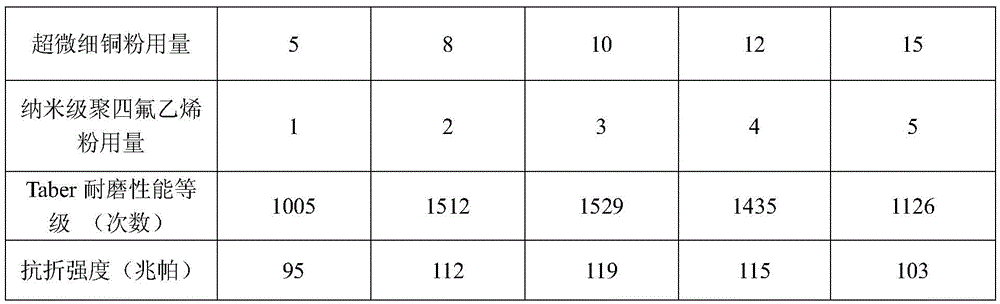

[0008] 2. Preparation of a working abrasive layer; the working abrasive layer includes a resin bond and a mixed filler; the resin bond is an ultrafine phenolic resin; the mixed filler is calculated by volume ratio: ultrafine silicon carbide 15 with a particle size of 20 μm, Nanoscale SiO with a particle size of 0.05μm 2 3. Glass beads with a particle size of 8 μm 10, ultrafine copper powder with a particle size of 0.5 μm 5, ultrafine kaolin with a particle size of 20 μm 1, ultrafine talc powder with a particle size of 20 μm 1, nano-sized polytetrafluoroethylene powder with a particle size of 0.05 μm 1; diamond 1, CBN25.

[0009] The working abrasive layer is integrated with the substrate according to the general method, that is, the CBN grinding disc;

Embodiment 2

[0011] 1. Prepare the matrix according to the general method;

[0012] 2. Preparation of a working abrasive layer; the working abrasive layer includes a resin bond and a mixed filler; the resin bond is an ultrafine phenolic resin; the mixed filler is calculated by volume ratio: ultrafine silicon carbide 20 with a particle size of 10 μm, Nanoscale SiO with a particle size of 0.03μm 2 5. Glass beads with a particle size of 15 μm 5, ultrafine copper powder with a particle size of 1.0 μm 8, ultrafine kaolin with a particle size of 15 μm 10, ultrafine talc powder with a particle size of 15 μm 3, nano-sized polytetrafluoroethylene powder with a particle size of 0.03 μm 2; diamond 10, CBN10.

[0013] The working abrasive layer is integrated with the substrate according to the general method, that is, the CBN grinding disc;

Embodiment 3

[0015] 1. Prepare the matrix according to the general method;

[0016] 2. Preparation of a working abrasive layer; the working abrasive layer includes a resin bond and a mixed filler; the resin bond is an ultrafine phenolic resin; the mixed filler is calculated by volume ratio: ultrafine silicon carbide 17 with a particle size of 15 μm, Nanoscale SiO with a particle size of 0.04μm 2 4. Glass beads with a particle size of 12 μm 8, ultrafine copper powder with a particle size of 0.7 μm 10, ultrafine kaolin with a particle size of 17 μm 5, ultrafine talc powder with a particle size of 18 μm 2, nano-sized polytetrafluoroethylene powder with a particle size of 0.04 μm 3; diamond 6. CBN15.

[0017] The working abrasive layer is integrated with the substrate according to the general method, that is, the CBN grinding disc;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com