A kind of gan-based LED epitaxial structure and growth method of n-type gan structure

A technology of epitaxial structure and growth method, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven lateral expansion of holes, large lattice mismatch of superlattice, insufficient electron blocking, etc., to prevent electron overflow , Reduce crystal growth dislocations and cracks, improve the effect of antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

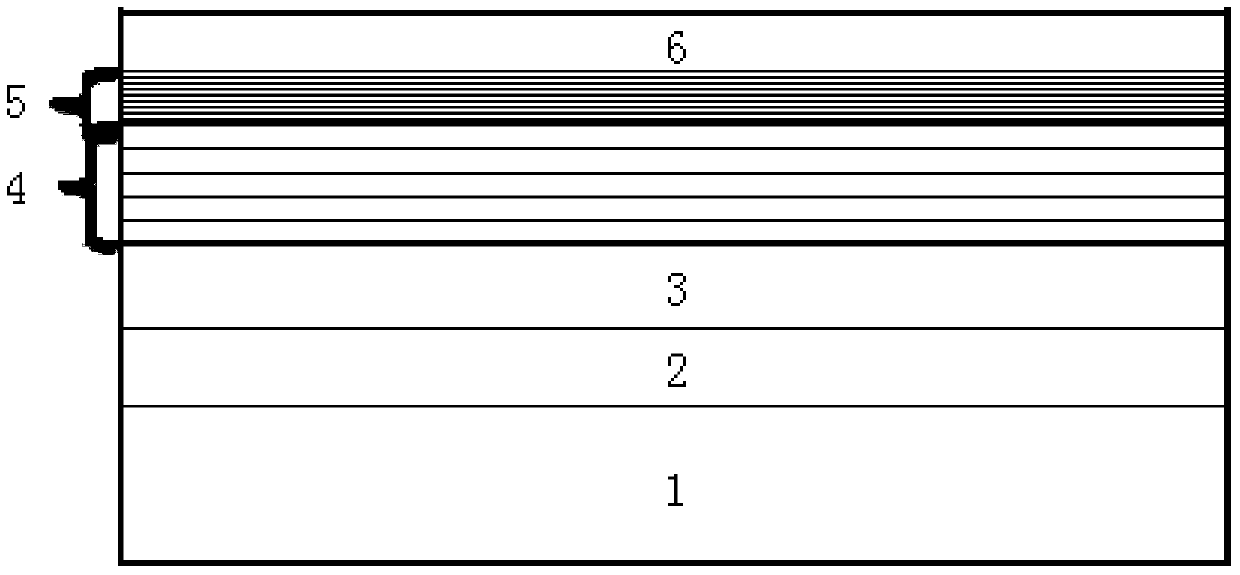

[0043] A GaN-based LED epitaxial structure with an n-type GaN structure, including a substrate layer 1, a buffer layer, an n-type structure 4, a multi-quantum well light-emitting layer 5, and a p-type structure 6 arranged sequentially from bottom to top;

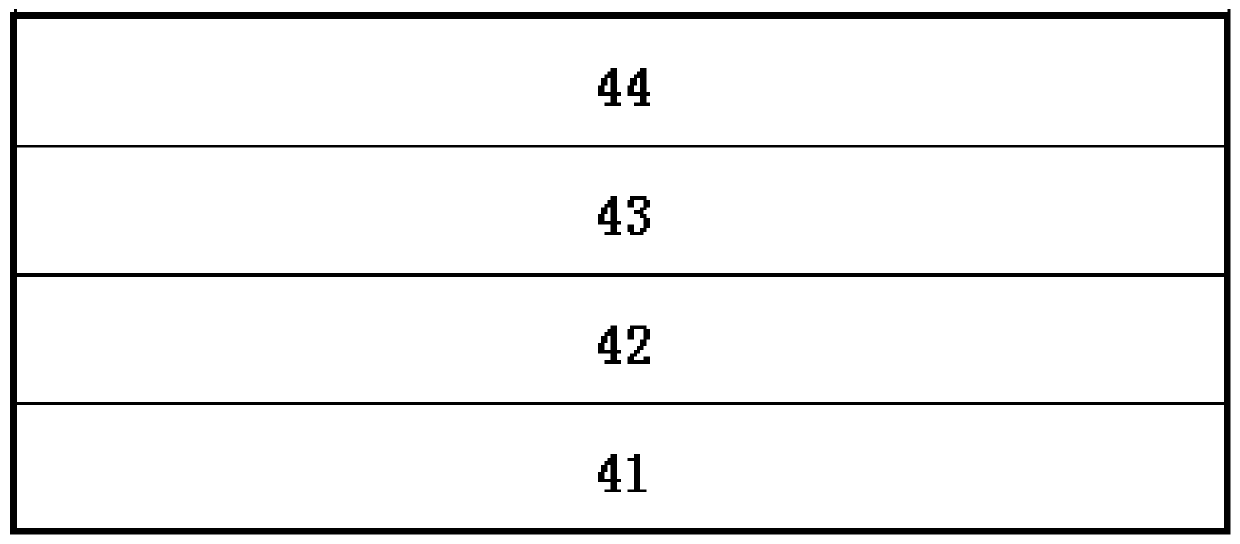

[0044] The n-type structure 4 includes an n-type GaN layer with low doped Si concentration gradient, a Si-doped n-type AlGaN layer, a u-type GaN layer, and a highly Si-doped n-type GaN layer arranged in sequence from bottom to top.

[0045] The Si doping concentration of the low-doped Si concentration gradient n-type GaN layer is 5E18-2E19 / cm 3 ; The Si doping concentration of the n-type AlGaN is 5E17-5E19 / cm 3 ; The Si doping concentration of the highly doped Si n-type GaN layer is 1.5E19-5E20 / cm 3 .

[0046] The thickness of the n-type GaN layer with low-doped Si concentration gradient is 2-3 μm; the thickness of the n-type AlGaN layer is 20-60 nm; the thickness of the u-type GaN layer is 20-40 nm; the highly doped Si T...

Embodiment 2

[0051] The method for growing LED epitaxial structure as described in embodiment 1, comprises the following steps:

[0052] (1) Carry out nitriding treatment to substrate layer 1; The preferred sapphire substrate of substrate layer 1 described here, utilizes metal-organic chemical vapor deposition (MOCVD) equipment to grow on the sapphire substrate with metal-organic chemical vapor deposition, using high Pure H 2 or high purity N 2 or high purity H 2 and N 2 The mixed gas as the carrier gas, high-purity NH 3 As a N source, the reaction chamber pressure is 200mbar;

[0053] (2) A buffer layer is grown on the substrate layer 1 after nitriding treatment, that is, a nucleation layer 2 and a non-doped gallium nitride layer 3 are grown sequentially; Layer 2, thickness 20-40nm;

[0054] (3) growing the n-type structure 4 on the buffer layer includes:

[0055] a. The growth temperature of n-type GaN layer with low-doped Si concentration gradient is 1100°C, the growth pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com